Injection molding machine

A technology for injection molding machines and rotating motors, applied in the field of mechanical equipment, can solve problems such as difficult quality control, high manual labor intensity, and inconvenient operation, and achieve the effects of stable production quality, reduced labor intensity, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without some of these specific details. The following description of the embodiments is only to provide a better understanding of the present invention by showing examples of the present invention.

[0014] The technical solutions of the embodiments of the present invention will be described below with reference to the accompanying drawings.

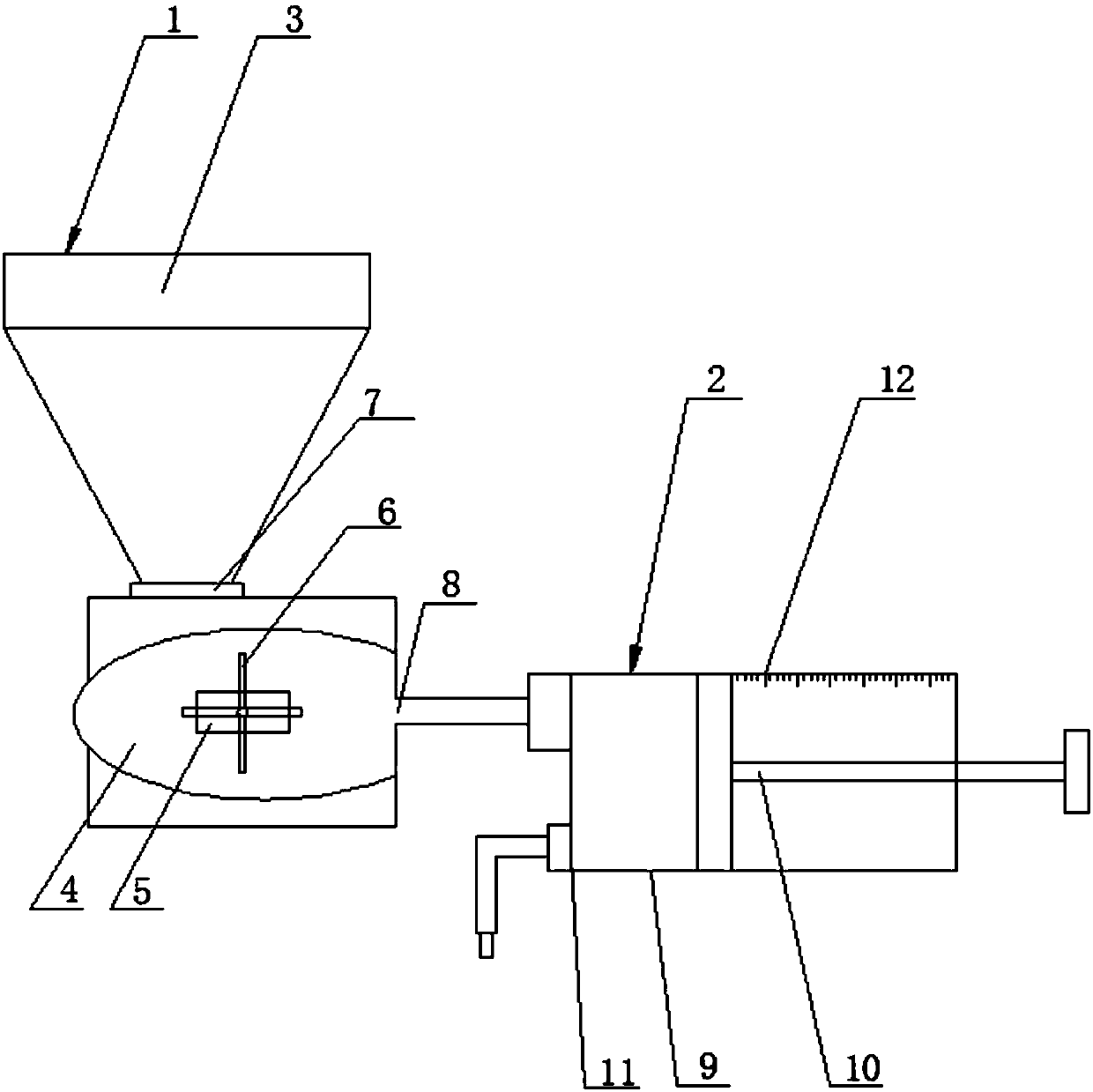

[0015] Such as figure 1 As shown, the present invention provides a kind of injection molding machine, comprises: feeding device 1 and feeding device 2, and described feeding device 1 comprises: hopper 3, mixer 4, rotating motor 5, agitating blade 6; The upper end of the device 4 is provided with a feed inlet 7, and the feed inlet 7 is connected to the hopper 3; the side of the mixer ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap