Bunker cleaning mechanical hand and coal bunker blockage cleaning robot

A manipulator and arm technology, applied in the field of coal bunker cleaning robots, can solve the problems of easily damaged ground coal bunker, low cleaning efficiency, poor safety, etc., to ensure safety and efficiency, light and compact structure, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1 of the present invention describes a clearing manipulator.

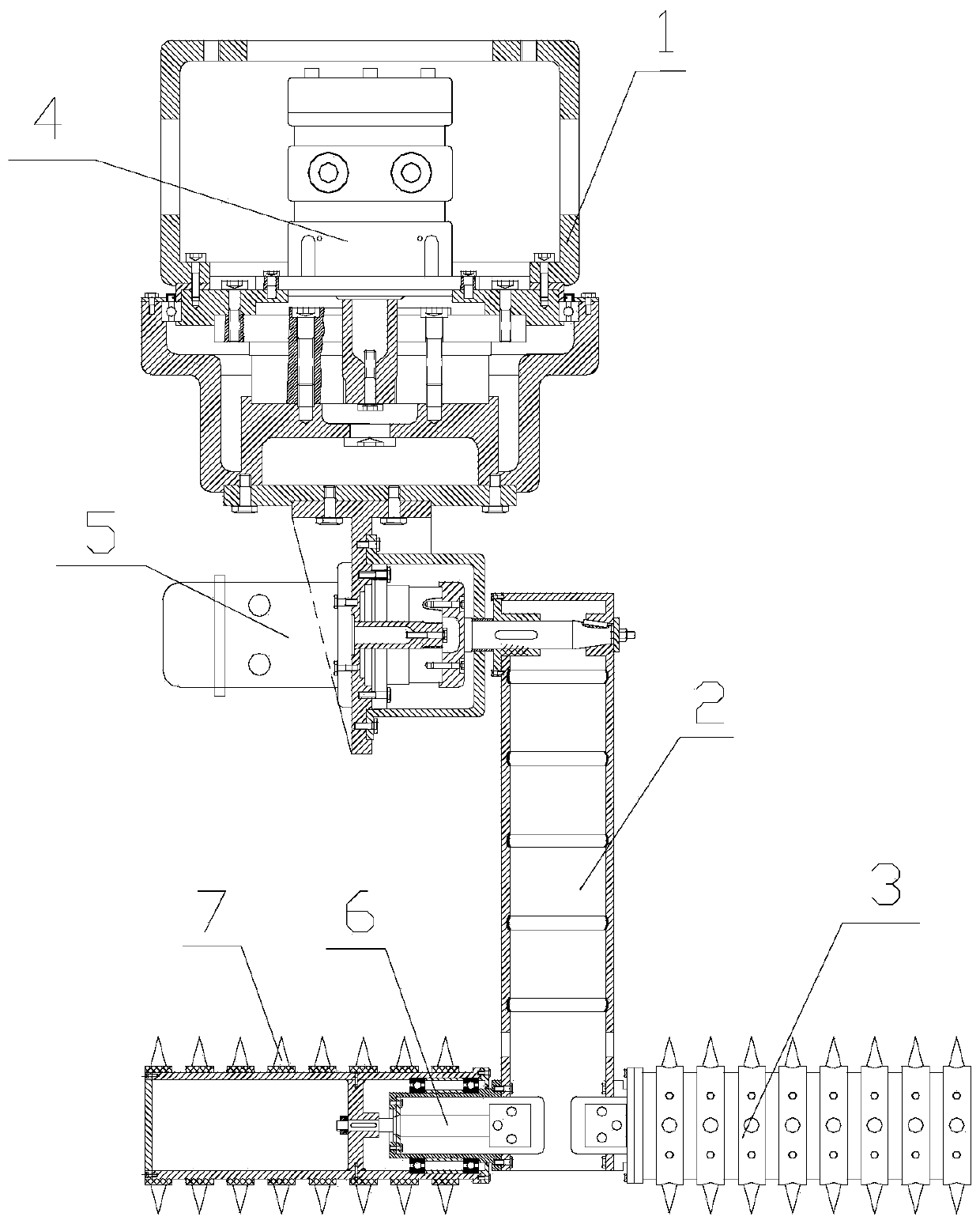

[0073] Such as figure 1 As shown, the clearing robot includes a base 1, a robot arm 2 and a scraper 3 connected sequentially from top to bottom.

[0074] Among them, the direction here only refers to the figure 1 The orientation in , may be different from the above orientation when used.

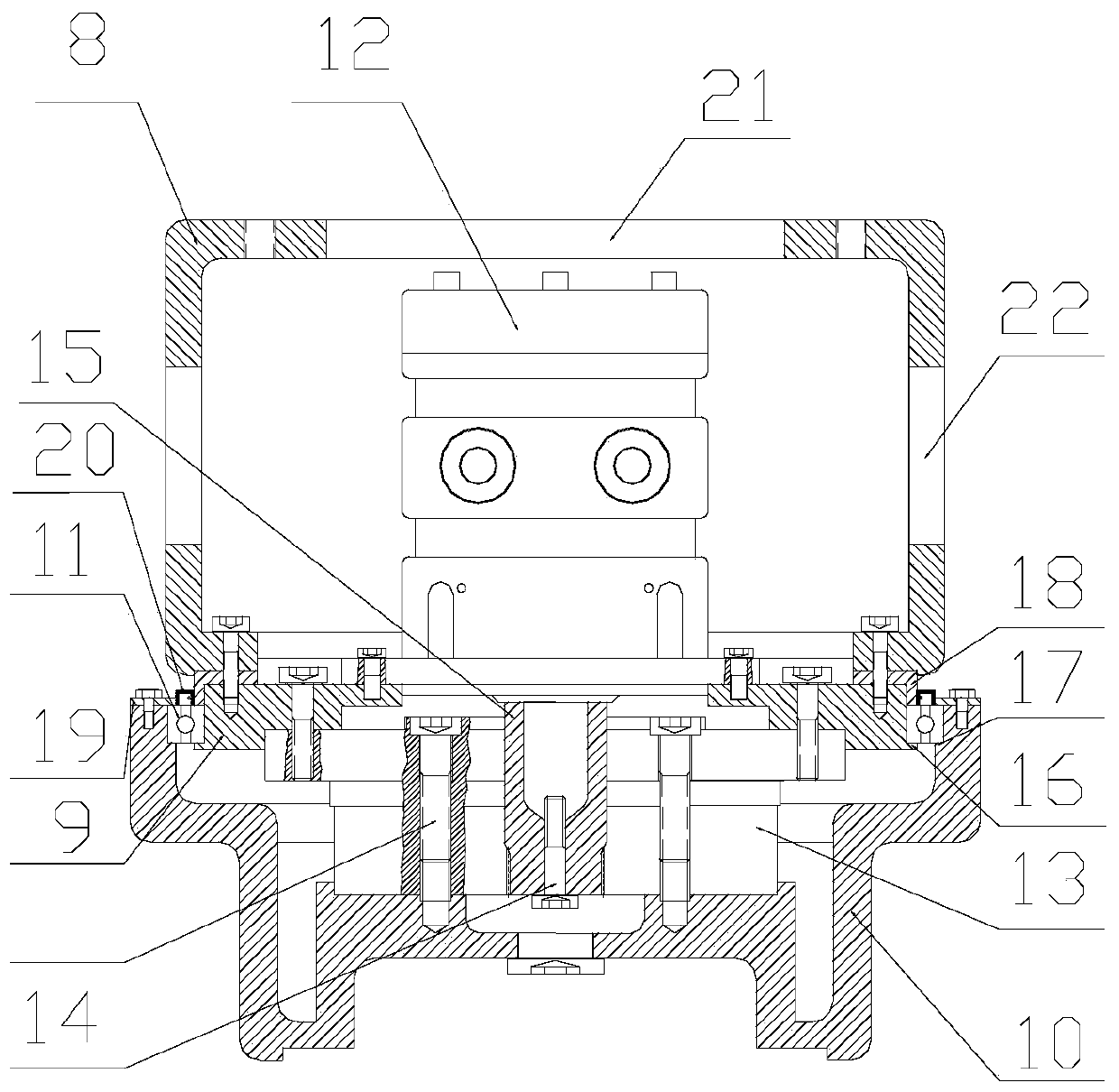

[0075] A first rotary drive mechanism 4 is installed in the base 1 .

[0076] The function of the first rotation driving mechanism 4 is to drive the manipulator arm 2 to rotate in the horizontal direction, which is the first degree of freedom.

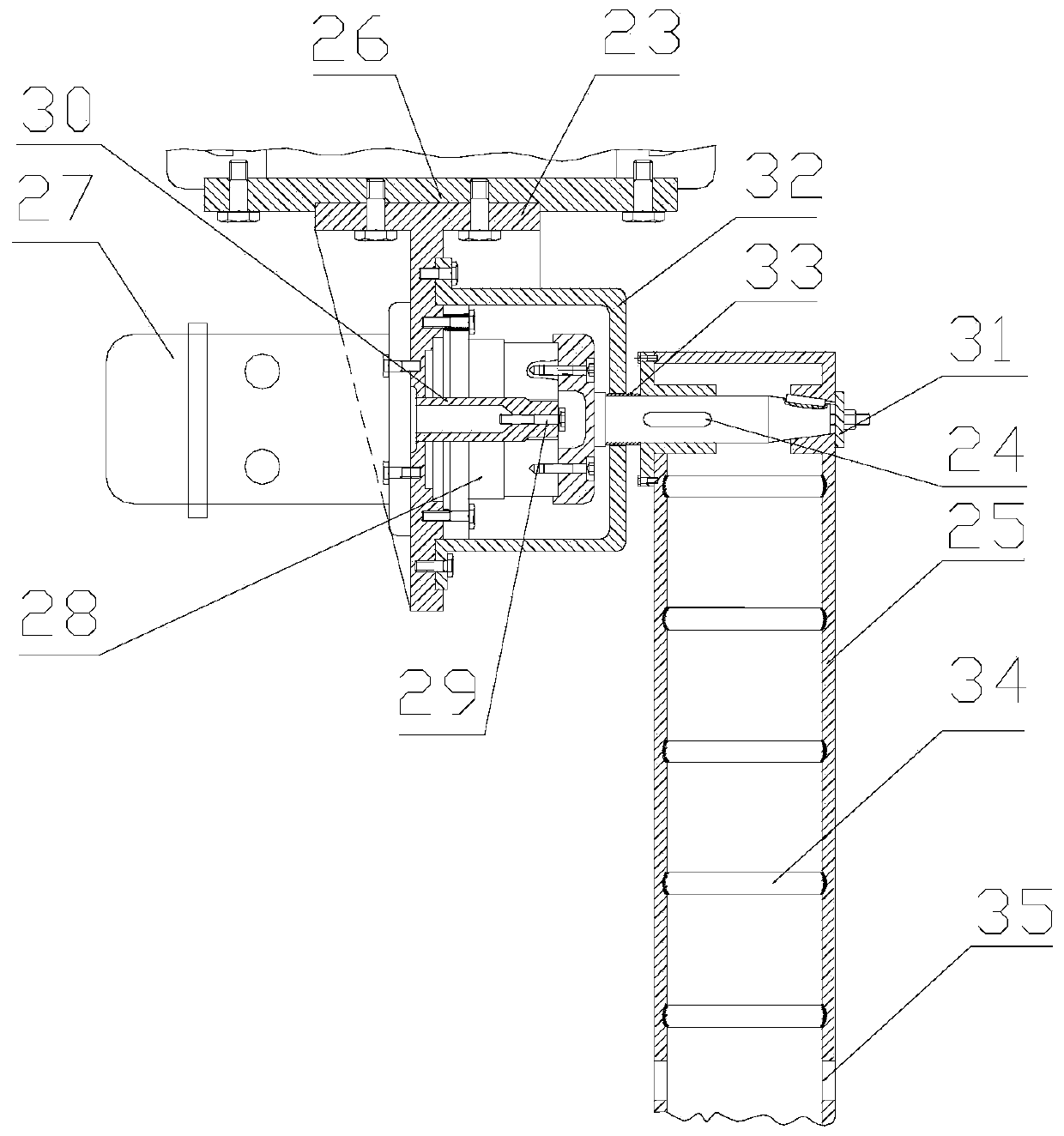

[0077] A second rotary drive mechanism 5 is disposed on the upper end of the manipulator arm 2 .

[0078] The function of the second rotary driving mechanism 5 is to drive the manipulator arm 2 to swing in the vertical plane, which is the second degree of freedom.

[0079] The swing angle, for example, can be within the range of 0°-90°.

[0080] That is, the manipu...

Embodiment 2

[0162] Embodiment 2 describes a coal bunker cleaning robot to meet the requirements of cleaning large ground coal bunkers.

[0163] The coal bunker unclogging robot includes a controller, a gas source and the bunker clearing manipulator in Embodiment 1 above. Wherein, the air source supplies air to the air motors of the above-mentioned rotary drive mechanisms through pipelines.

[0164] In particular, it should be noted that when the air source is the No. 3 air motor 39, its air supply pipeline can pass through the air inlet 35 at the lower part of the arm body 25, then go down through the arm body 25, and connect to the No. 3 air motor 39 on the gas road.

[0165] The controller is connected to the first rotary drive mechanism 4 , the second rotary drive mechanism 5 , and the third rotary drive mechanism 6 respectively through lines, and the controller can realize the three-degree-of-freedom control of the clearing manipulator in the above-mentioned embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com