Magnetic force adjusting type textile spool

An adjustable yarn bobbin technology, applied in the textile field, can solve the problems of cumbersome operation, time-consuming and labor-intensive, inconvenient yarn winding, etc., and achieve the effect of uniformity and stable chemical properties of the whole body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

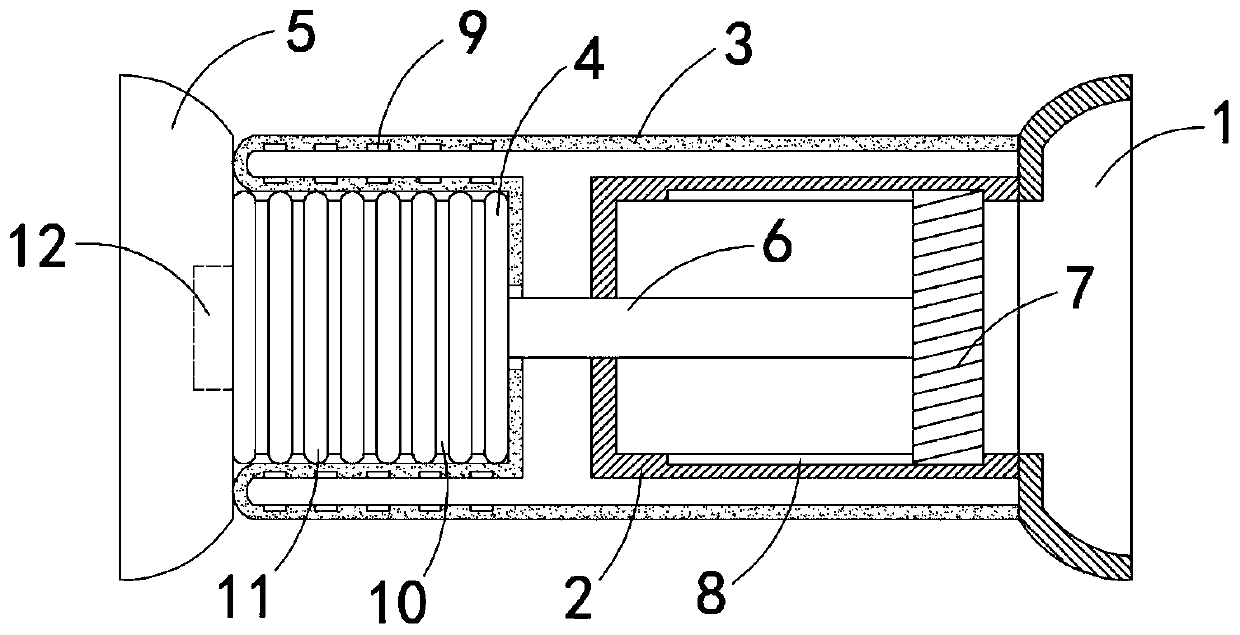

[0022] Such as Figure 1-4 As shown, a magnetically adjustable textile yarn tube includes a base 1, a fixed tube 2 is fixedly connected to the side wall of the base 1, the outer cover of the fixed tube 2 is provided with a flexible cylindrical bag 3, and one end of the flexible cylindrical bag 3 is connected to the base The side wall of 1 is fixedly connected, and the other end of the flexible cylindrical bag 3 extends inward and is fixedly connected with a magnetically stretchable bellows 4. Specifically, the magnetically stretchable bellows 4 includes a plurality of magnetic rings 10 and elastic rings 11, and a plurality of The magnetic rings 10 and the elastic rings 11 are fixedly connected alternately, the elastic force of the elastic rings 11 is greater than the suction force between the adjacent magnetic rings 10 , and the end of the magnetically stretchable bellows 4 away from the base 1 is fixedly connected with the fixing seat 5 .

[0023] The flexible cylindrical bag...

Embodiment 2

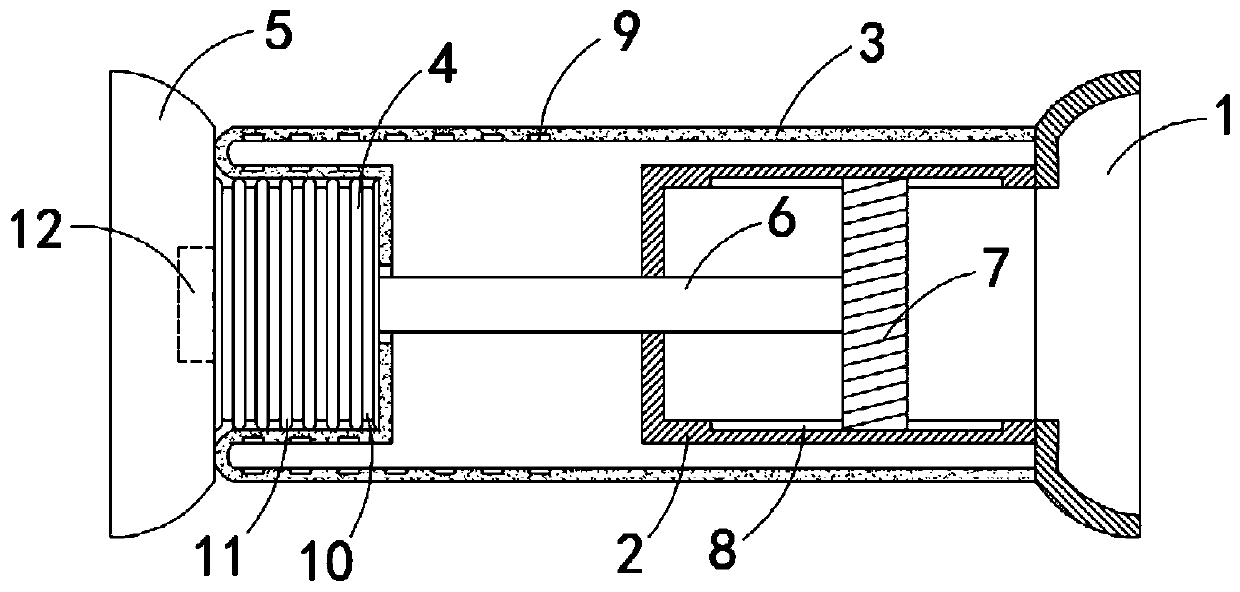

[0026] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the flexible cylindrical bag 3 is filled with magnetorheological fluid 13, which not only enables the flexible cylindrical bag 3 to have more stable chemical properties, but also can utilize magnetic The rheological fluid 13 exhibits characteristics of high viscosity and low fluidity in the magnetic field range, so that the flexible cylindrical bladder 3 is not easily deformed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com