Battery diaphragm coating head cleaning wastewater treatment device and treatment method

A technology for cleaning wastewater and battery diaphragms, applied in natural water treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of difficult guarantee of effluent water quality, high requirements for operators, and high cost of wastewater treatment, and achieve easy Automatic control, stable and reliable system operation, and good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

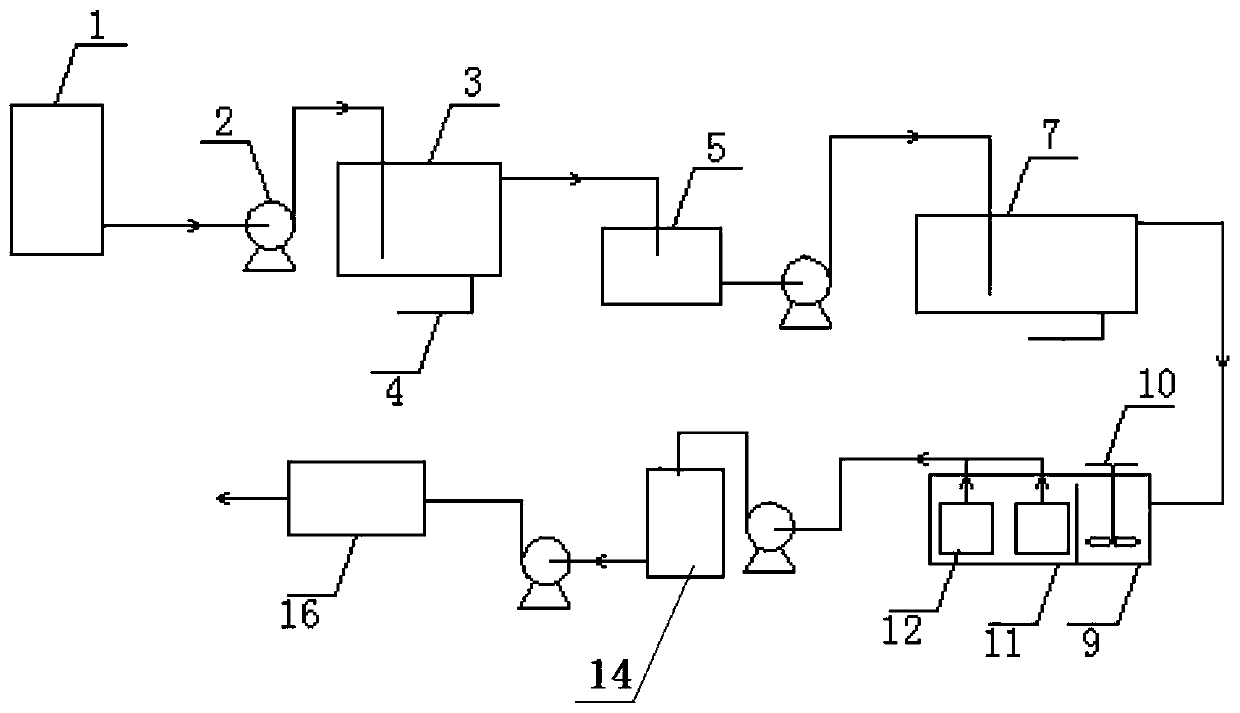

Method used

Image

Examples

Embodiment 1

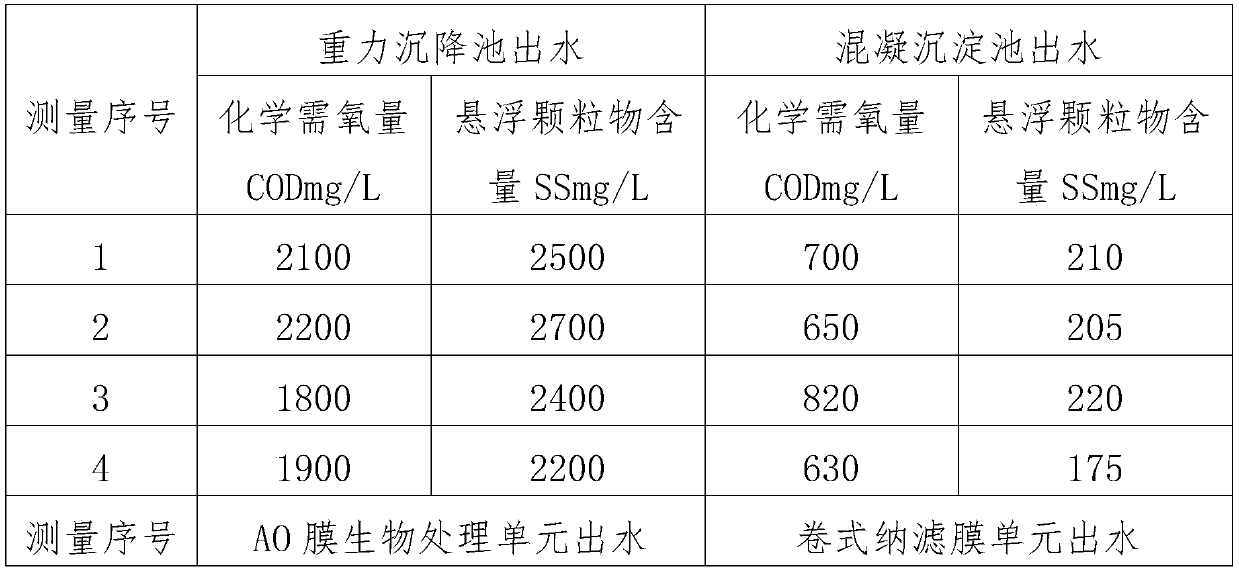

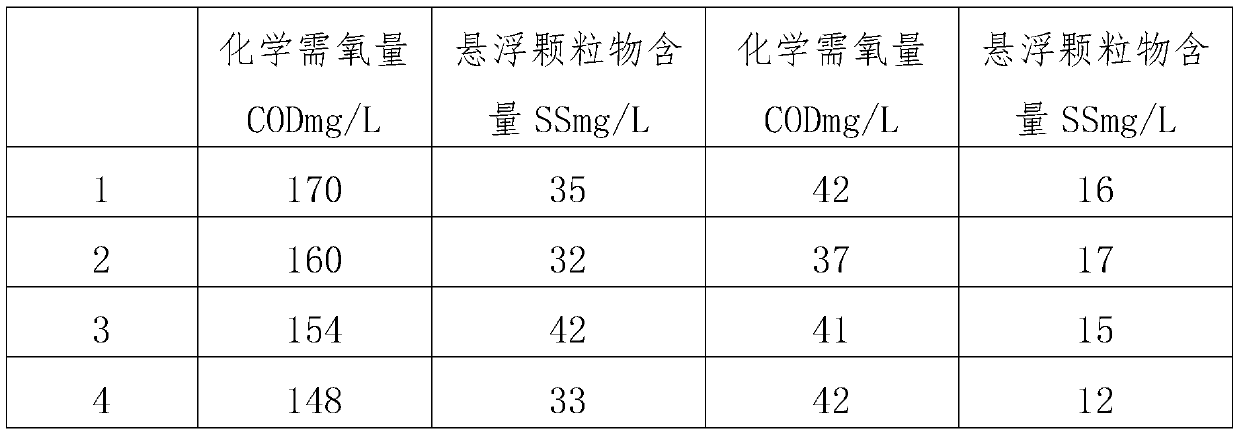

[0044]The used battery diaphragm coating head cleaning wastewater treatment device makes the battery diaphragm coating head cleaning wastewater flow through the gravity sedimentation tank 3, the coagulation sedimentation tank 7, the AO membrane biological treatment unit and the roll-type nanofiltration membrane unit 16 for treatment, so that The battery diaphragm coating head cleaning wastewater stays in the gravity settling tank for 8 hours, uses polyaluminum chloride PAC flocculant concentration of 100ppm, anionic polyacrylamide PAM coagulant concentration of 4ppm, and controls the speed of the agitator in the anaerobic tank to 85r / min, the DO value of the dissolved oxygen content in the anoxic pool 9 is 0.15mg / L, and the clear water treated by the roll-type nanofiltration membrane system unit 16 is sent to the reservoir for recycling, and the roll-type nanofiltration membrane system unit 16 is running The pressure is 0.65Mpa.

[0045] The above-mentioned embodiment 1 is us...

Embodiment 2

[0050] The used battery diaphragm coating head cleaning wastewater treatment device makes the battery diaphragm coating head cleaning wastewater flow through the gravity sedimentation tank 3, the coagulation sedimentation tank 7, the AO membrane biological treatment unit and the roll-type nanofiltration membrane unit 16 for treatment, so that The battery diaphragm coating head cleaning wastewater stays in the gravity settling tank for 12 hours. The concentration of polyaluminum chloride PAC flocculant is 100ppm, the concentration of anionic polyacrylamide PAM coagulant is 5ppm, and the rotation speed of the agitator in the anoxic tank is controlled to 100r. / min, the DO value of the dissolved oxygen content in the anoxic pool 9 is 0.2mg / L, and the clear water treated by the roll-type nanofiltration membrane system unit 16 is sent to the reservoir for recycling, and the roll-type nanofiltration membrane system unit 16 is running The pressure is 0.7Mpa.

[0051] The above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com