Functional layer ink, preparation method of photoelectric device functional layer as well as photoelectric device

A technology for optoelectronic devices and functional layers, applied in the field of inkjet printing, can solve the problem that the functional layer ink is difficult to form a functional layer of uniform thickness, and achieve the effect of preventing color mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

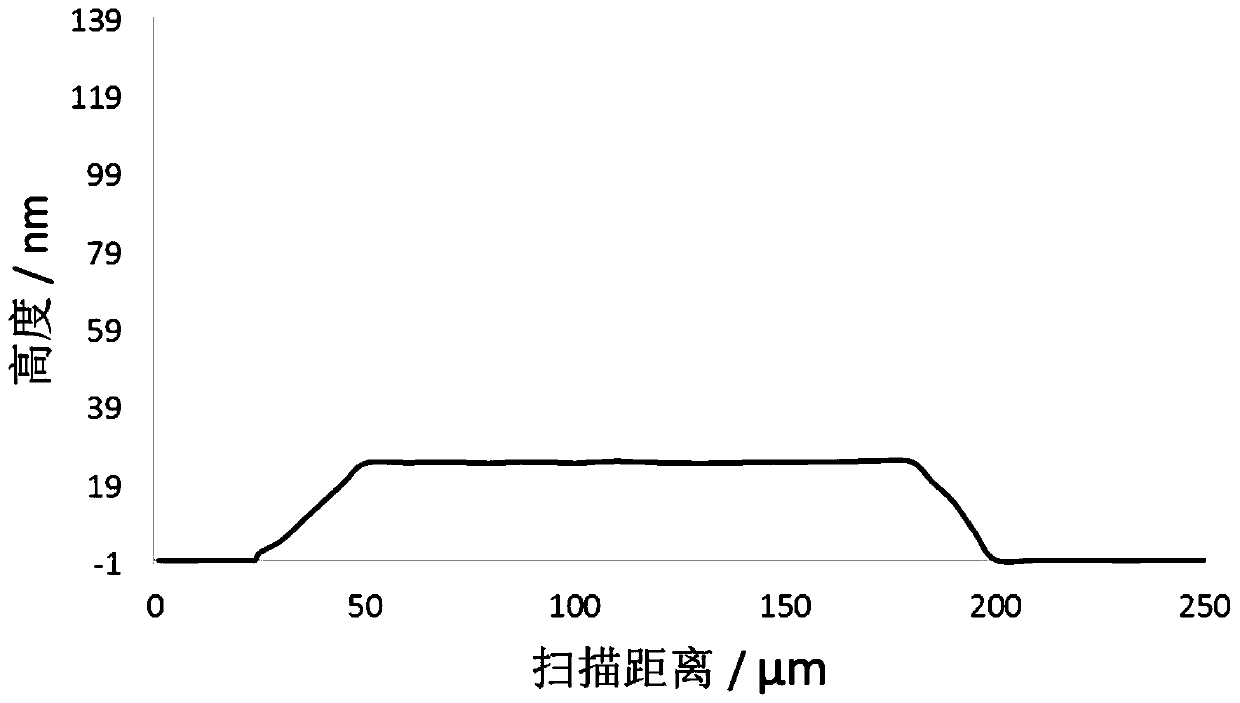

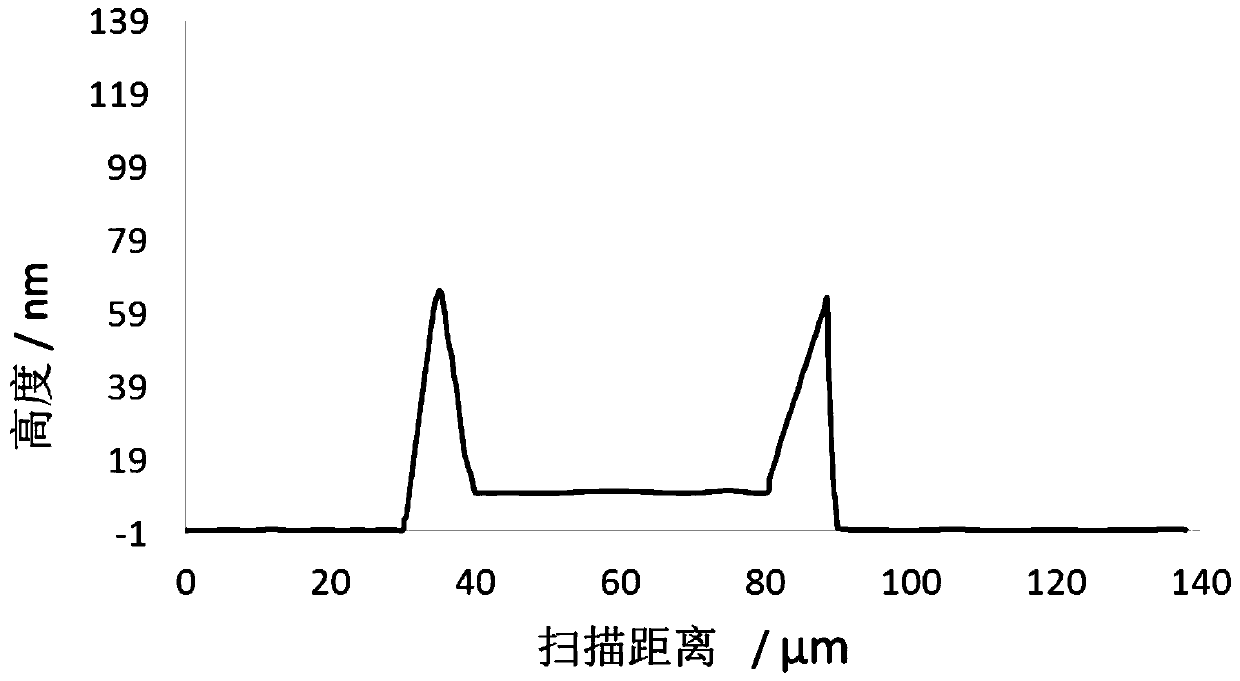

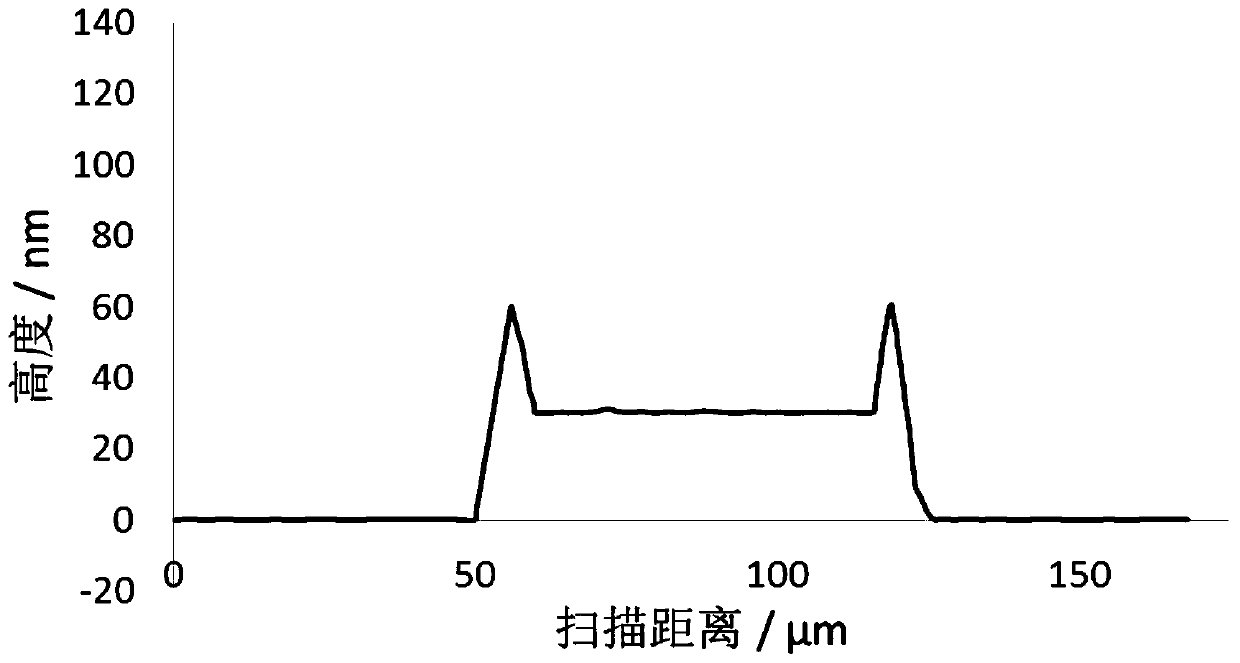

[0046] In another typical embodiment of the present application, a method for preparing a functional layer of a photoelectric device is provided, the preparation method comprising: providing a base layer; using a film-forming process to arrange any one of the above-mentioned functional layer inks on the base layer, and During the implementation of the film forming process, at least part of the main solvent in the functional layer ink is volatilized and the spreading regulator is precipitated and solidified to form a functional layer precursor film; and the functional layer precursor film is heated to remove the spreading regulator and the remaining main solvent to form a functional layer. layer.

[0047] The functional layer ink of the present application contains a spreading regulator, and since the melting point of the spreading regulator is greater than or equal to 15°C, in the conventional functional layer preparation process, the main solvent in the functional layer ink wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com