Method for performing laser hardening on leading edge on large-thickness blade of steam turbine

A large thickness, steam turbine technology, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve problems such as inability to meet hardening requirements, and achieve the effect of easy implementation, meeting hardening requirements, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

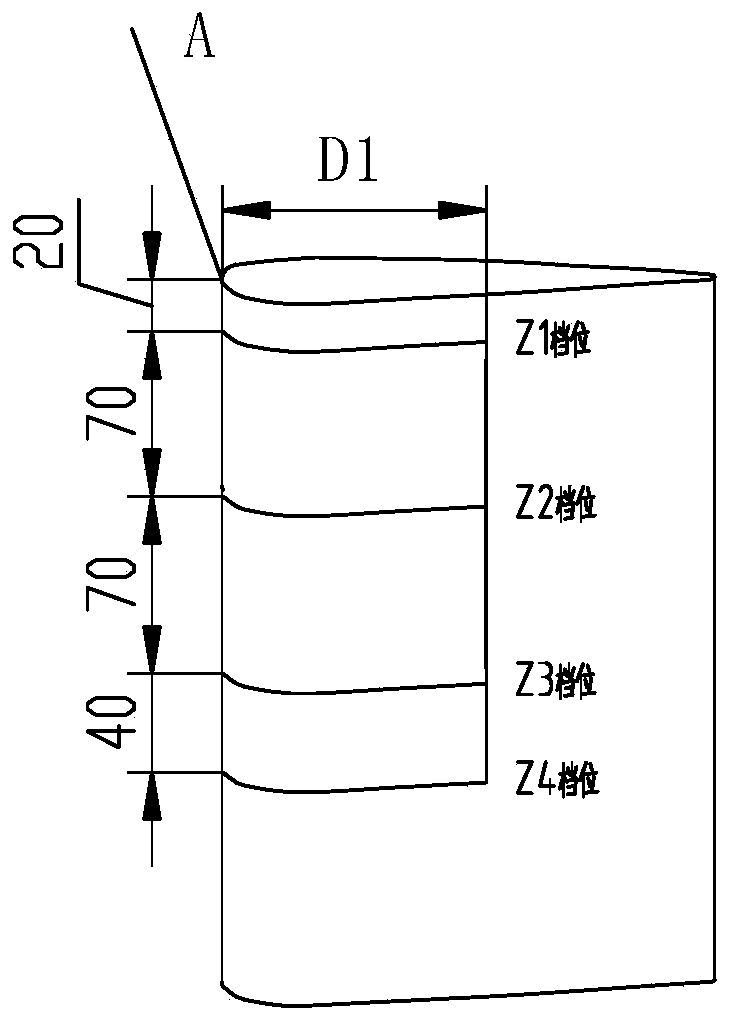

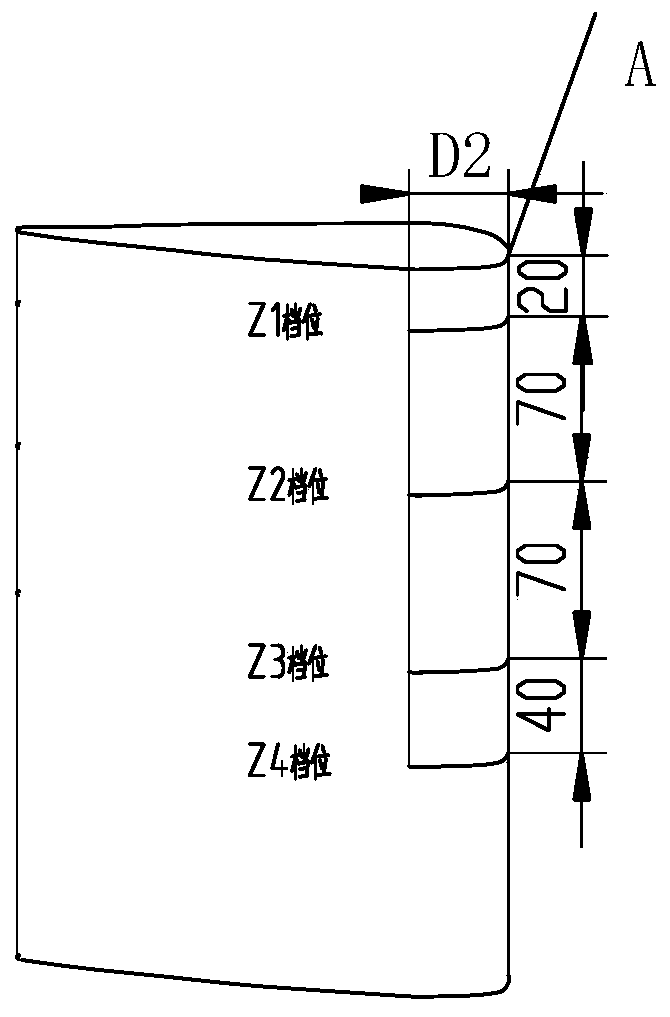

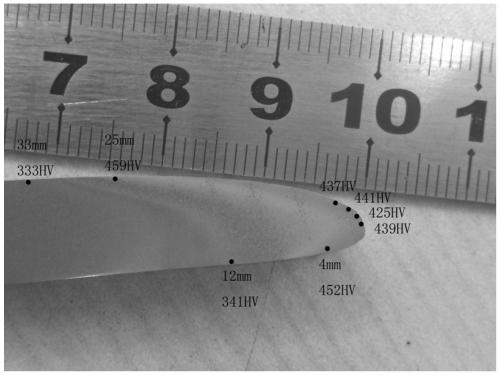

[0025] In this embodiment, a method for laser hardening of the steam inlet side of a large-thickness steam turbine blade comprises the following steps: 1) pretreatment, before laser hardening of the blade, the hardened area of the blade is first degreased, dedusted, and brushed Light absorbing agent and drying to increase the absorption of laser energy in the laser irradiation area; 2) Laser hardening, laser hardening is performed on the back of the blade according to the required size, the speed of back arc laser hardening is 80mm / min, the hardening temperature is 1400°C, laser hardening Use an infrared thermometer to monitor the hardening temperature in real time, and adjust the input laser power according to the temperature measurement results to ensure that the temperature of the spot irradiation area is uniform throughout the process, without large fluctuations, and the hardening is completed on the back arc surface Immediately after that, laser harden the inner arc of t...

Embodiment 2

[0027] In this embodiment, a method for laser hardening of the steam inlet side of a large-thickness steam turbine blade comprises the following steps: 1) pretreatment, before laser hardening of the blade, the hardened area of the blade is first degreased, dedusted, and brushed Light absorbing agent and drying to increase the absorption of laser energy in the laser irradiated area; 2) Laser hardening, laser hardening is performed on the back of the blade according to the required size, the speed of back arc laser hardening is 115mm / min, the hardening temperature is 1600°C, laser hardening Use an infrared thermometer to monitor the hardening temperature in real time, and adjust the input laser power according to the temperature measurement results to ensure that the temperature of the spot irradiation area is uniform throughout the process, without large fluctuations, and the hardening is completed on the back arc surface Immediately after that, laser harden the inner arc of t...

Embodiment 3

[0029] In this embodiment, a method for laser hardening of the steam inlet side of a large-thickness steam turbine blade comprises the following steps: 1) pretreatment, before laser hardening of the blade, the hardened area of the blade is first degreased, dedusted, and brushed Light absorbing agent and drying to increase the absorption of laser energy in the laser irradiation area; 2) Laser hardening, laser hardening on the back of the blade according to the required size, the speed of back arc laser hardening is 150mm / min, the hardening temperature is 1800°C, laser hardening Use an infrared thermometer to monitor the hardening temperature in real time, and adjust the input laser power according to the temperature measurement results to ensure that the temperature of the spot irradiation area is uniform throughout the process, without large fluctuations, and the hardening is completed on the back arc surface Immediately after that, laser harden the inner arc of the blade. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com