Rotary drill string directional drilling short section and drilling method

A directional drilling and sub-joint technology, which is used in directional wells, sub-joints for directional drilling operations in horizontal wells, and drilling fields, can solve the problems of shortening the ratio of drill string rotation, instability of screw drilling tools, affecting friction reduction and speed increase, etc. , to reduce friction, reduce the risk of sticking, and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

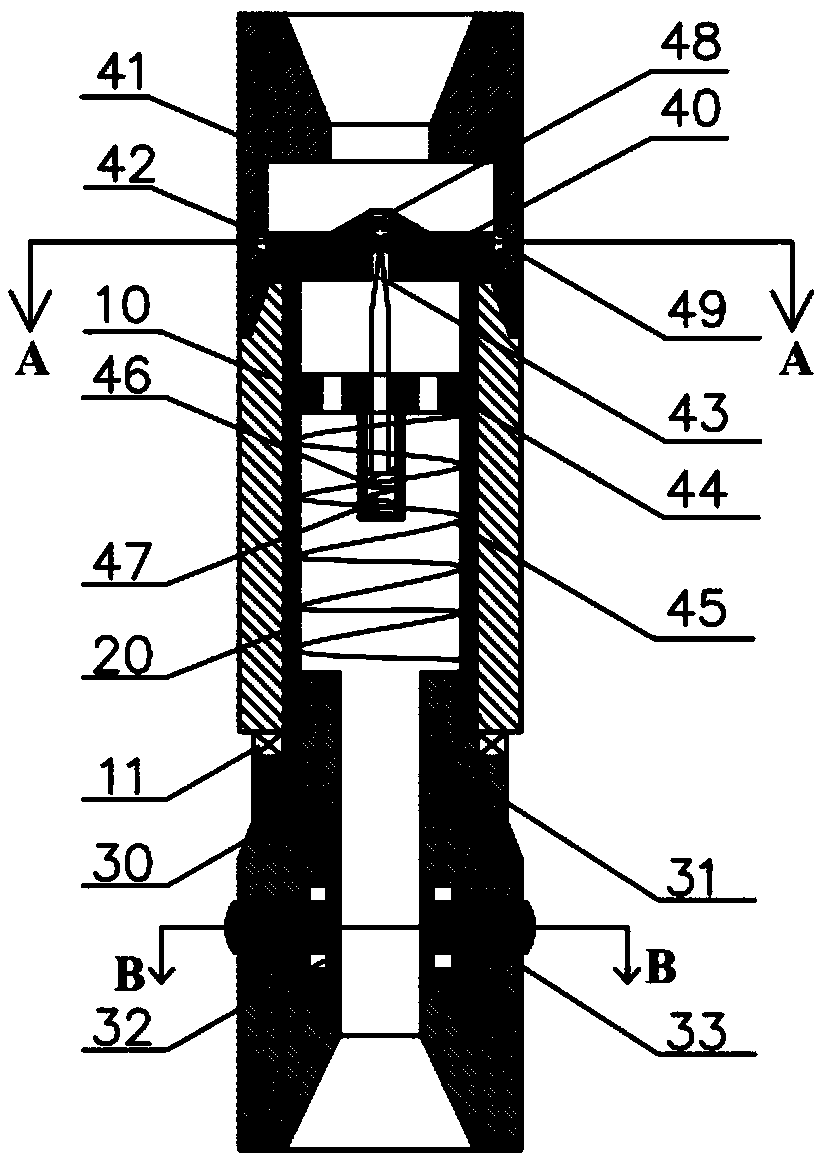

[0033] figure 1 Schematically shows a rotatable drill string directional drilling sub according to an embodiment of the present invention. The rotatable drill string directional drilling sub according to the invention can especially be used for drilling horizontal wells or directional wells.

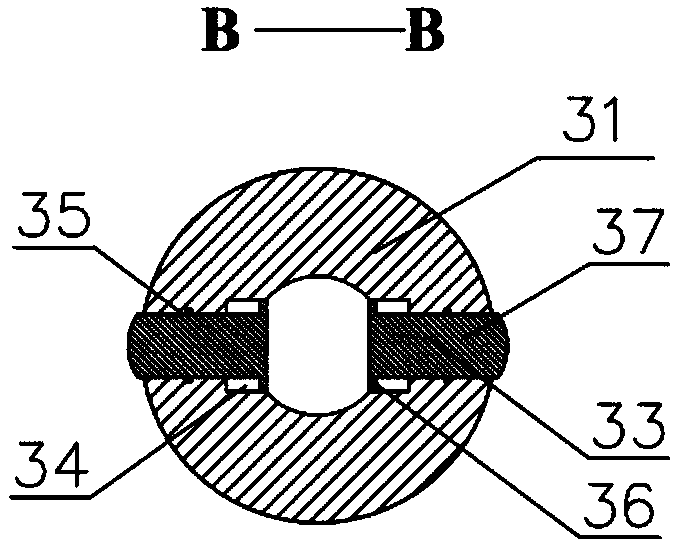

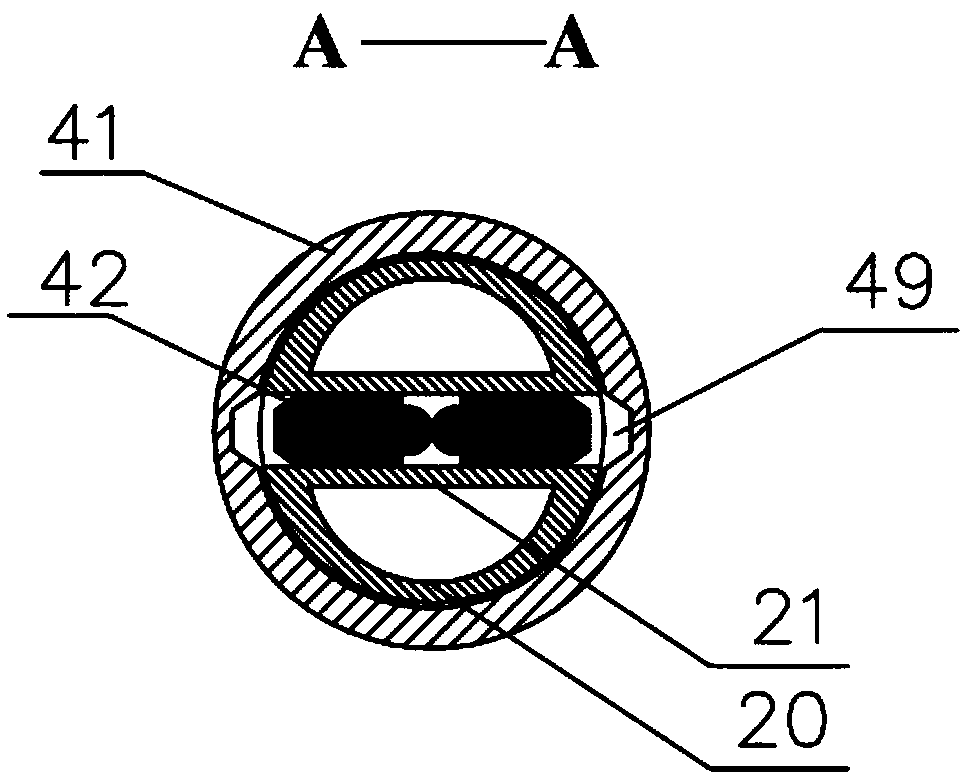

[0034] Such as figure 1 As shown, the pup joint of this embodiment includes a housing 10 . In this embodiment, the housing 10 is cylindrical. A cylinder body 20 is disposed inside the casing 10, and the cylinder body 20 is also cylindrical. The nipple of this embodiment also includes a switch assembly 40 . The switch assembly 40 is configured to separate the cylinder body 20 from the casing 10 for relative rotation when turned on, and connect the cylinder body 20 and the casing 10 for synchronous rotation when turned off. The pup joint of this embodiment also includes a well wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com