Stirring hook and making technology thereof

A technology of preparation process and stirring part, which is applied in the field of stirring hook and its preparation process, can solve the problems of high production cost and achieve the effects of low production cost, good thermal processability and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

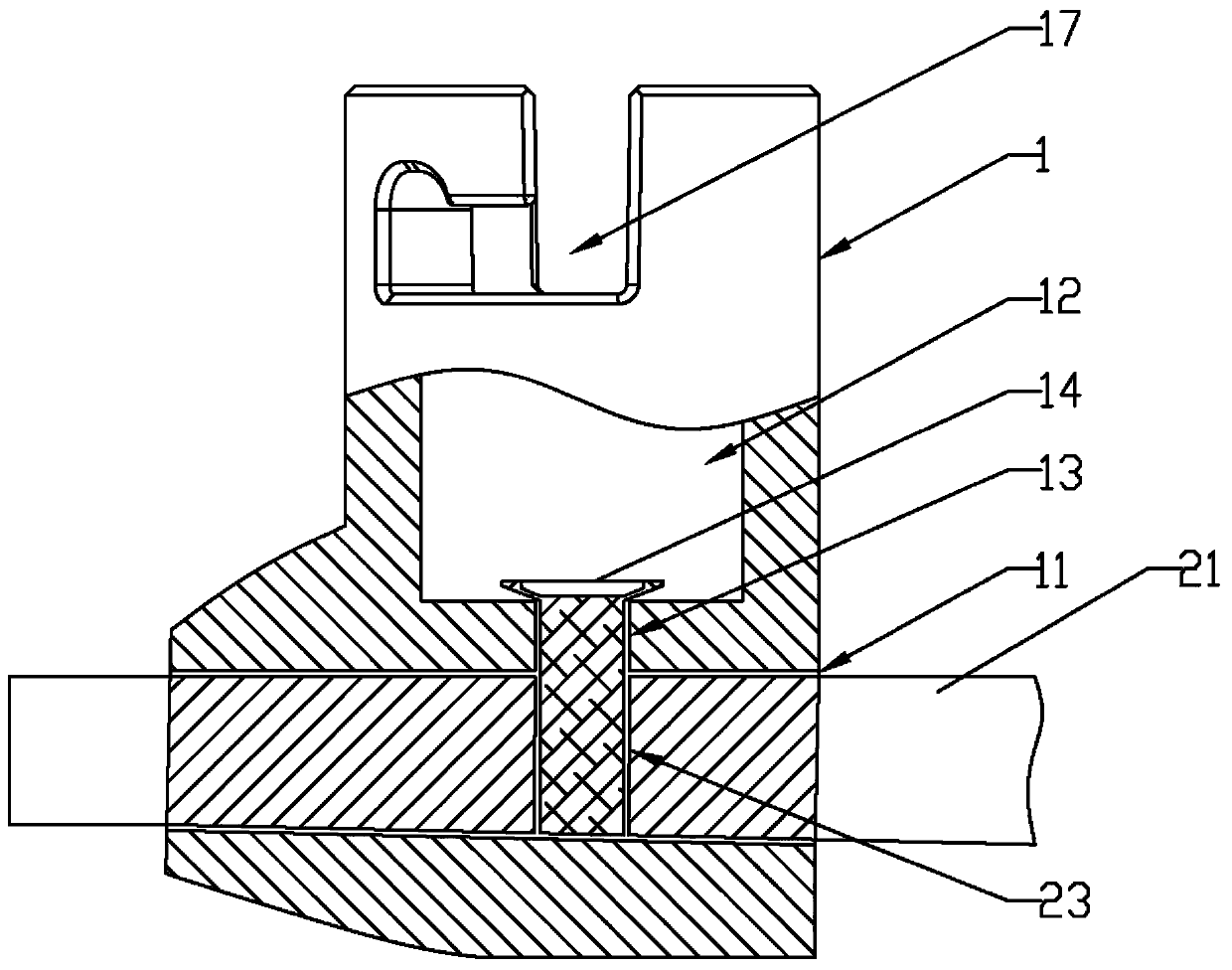

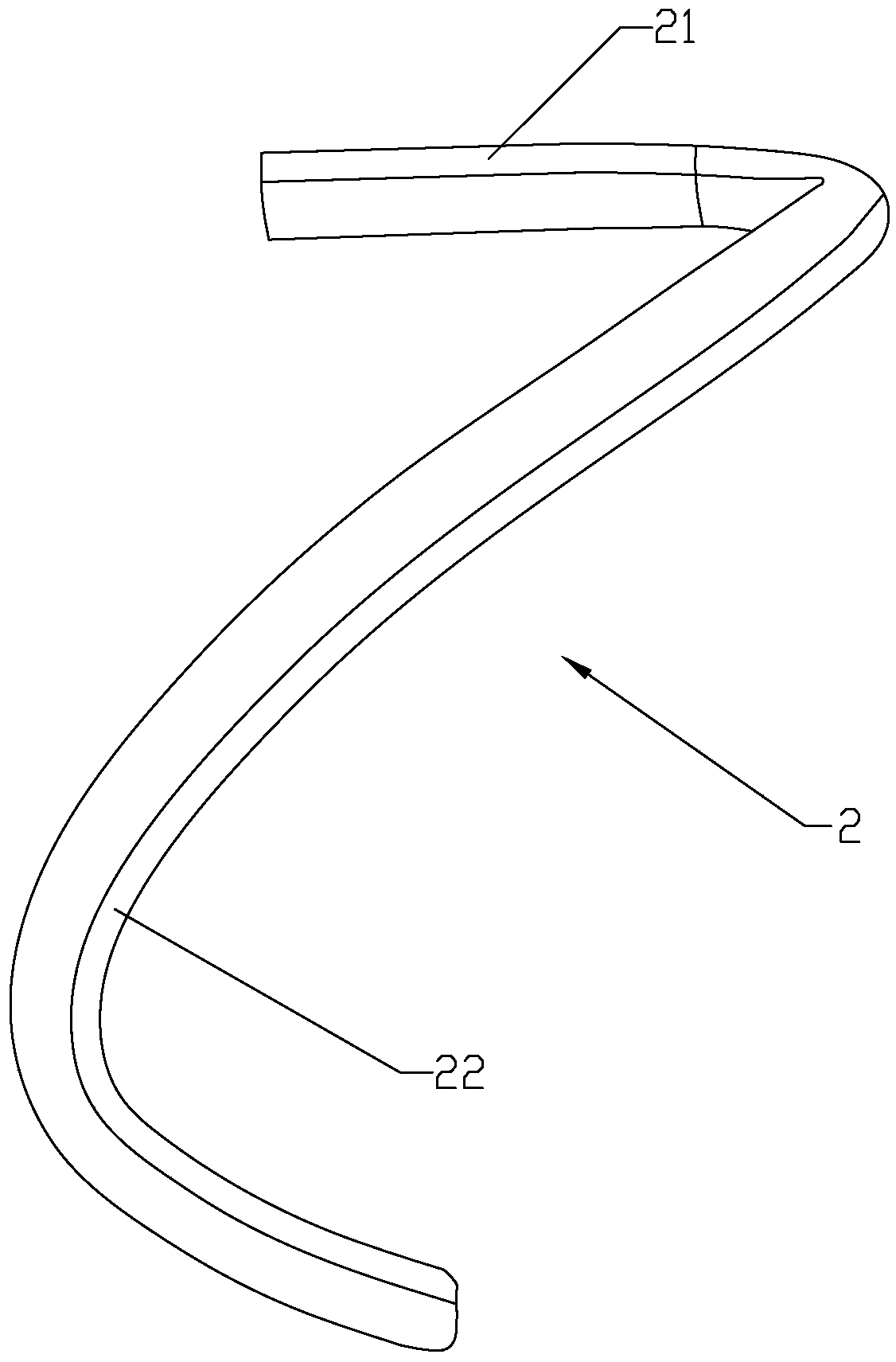

[0034] See figure 1 , a stirring hook, including a stirring hook body, the stirring hook body includes a connecting head 1 and a hook body 2, the connecting head 1 and the hook body 2 are fixedly connected. The stirring hook of the present invention adopts the connecting head 1 and the hook body 2 to be separately processed, and then assembled, which is convenient for production, can be assembled with hook bodies of different shapes at will, does not need repeated mold opening, and has low production cost. Specifically, the existing integrally formed stirring hooks are processed using the integral precision casting process, but in the present invention, only the connecting head 1 is required to be precision cast, and the hook body 2 is formed by bending a rod body, and the production cost is lower than that of the existing integrally formed Compared with the process, it can be reduced by more than 40%, which has good economic benefits.

[0035] In this embodiment, the hook bo...

Embodiment 2

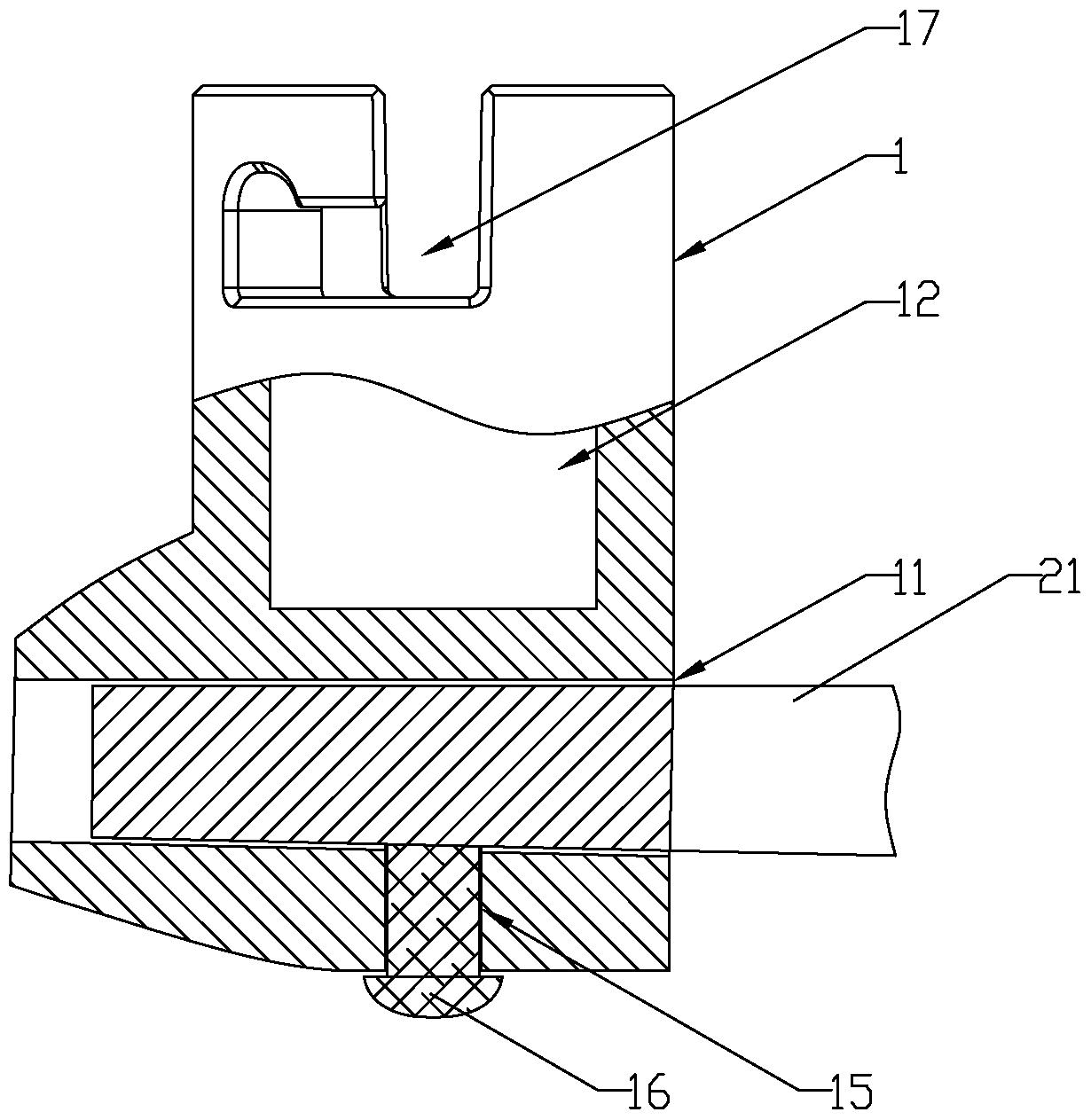

[0043] See figure 2 The difference between this embodiment and the above-mentioned embodiment 1 is that: the connecting head 1 and the hook body 2 are connected by a bolt. The bottom of the connector 1 is provided with a jack 15 , and a pin 16 is embedded in the jack 16 . The top of the pin 16 is in contact with the connecting portion 21 , and the connector 1 and the hook body 2 are fixed by the pin 16 . The setting of the above structure makes the connection head 1 and the hook body 2 firmly fixed, easy to disassemble, and low in cost. Another preferred embodiment of the present invention is: the connecting portion 21 is provided with a through hole or a blind hole at a position corresponding to the insertion hole 15 , and the top of the pin 16 is inserted into the through hole or the blind hole.

Embodiment 3

[0045] The difference between this embodiment and the above-mentioned embodiment 1 lies in that: the connecting head 1 and the hook body 2 are connected by welding, riveting or punching. The above-mentioned fixing methods through the screws 14 and the latches 16 are detachable fixed connection methods. When the detachable connection method is adopted, when replacing accessories of kitchen appliances to achieve different functions, only the hook body 2 needs to be replaced, and the connector 1 does not need to be replaced. Need to be replaced, easy to use and low cost. Or, the connecting head 1 and the hook body 2 of the present invention can also adopt non-detachable fixed connection methods, such as welding, riveting or stamping connection, etc., and can also realize arbitrary assembly of hook bodies 2 of different shapes without repeated mold opening, such as Purchase a certain amount of connecting heads 1 and hook bodies 2 of different shapes for assembly. Specifically, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com