Methanol synthesis catalyst

A methanol synthesis and catalyst technology, which is applied in catalyst activation/preparation, physical/chemical process catalyst, organic chemistry, etc., can solve problems such as short service life and poor thermal stability, and achieve the effect of improving economic benefits and reducing reaction procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

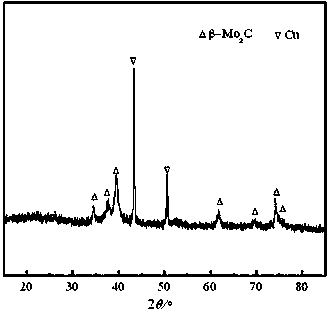

Image

Examples

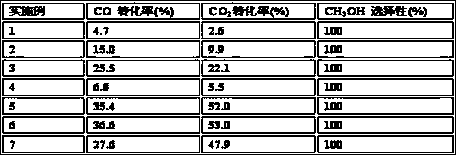

Embodiment 1

[0022] Weigh 2.9 g (NH 4 ) 6 Mo 7 o 24 ∙4H 2 O was ground for 10 min, dissolved in 150 mL ethanol, stirred for 24 h; 1.5 g Cu(NO 3 ) 2 ∙3H 2 O stirred for 1 h; slowly dropwise added 5.8 g C 3 h 9 OSi∙(CH 4 OSi) n ∙C 3 h 9 Si and 2 drops of ethylenediamine were stirred for 12 h; dried at 80 °C for 6 h; dried at 150 °C for 10 h; treated in a nitrogen atmosphere at 700 °C for 3 h to obtain the catalyst. The mass content of Cu is 5%, Mo 2 The mass content of C is 21%, SiO 2 The mass content is 74%. The sample has a pore size of 3.9 nm and a pore volume of 120mm 3 / g, the surface area is 117.3 m 2 / g. Methanol synthesis activity evaluation: feed gas composition CO 31.2%, CO 2 5.0%, H 2 61.8%. The reaction temperature was 150 °C, and the reaction pressure was 4 MPa. The results are shown in Table 1.

Embodiment 2

[0024] Weigh 2.9 g (NH 4 ) 6 Mo 7 o 24 ∙4H 2 O was ground for 10 min, dissolved in 150 mL ethanol, stirred for 24 h; 3.1 g Cu(NO 3 ) 2 ∙3H 2 O stirred for 1 h; slowly dropwise added 5.8 g C 3 h 9 OSi∙(CH 4 OSi) n ∙C 3 h 9 Si and 2 drops of ethylenediamine were stirred for 12 h; dried at 80 °C for 6 h; dried at 150 °C for 10 h; treated in a nitrogen atmosphere at 700 °C for 3 h to obtain the catalyst. Wherein the mass content of Cu is 10%, Mo 2 The mass content of C is 20%, SiO 2 The mass content is 70%. The sample has a pore size of 4.1 nm and a pore volume of 150 mm 3 / g, the surface area is 151.4 m 2 / g. The methanol synthesis activity was evaluated with reference to Example 1, and the results are shown in Table 1.

Embodiment 3

[0026] Weigh 2.9 g (NH 4 ) 6 Mo 7 o 24 ∙4H 2 O was ground for 10 min, dissolved in 150 mL ethanol, stirred for 24 h; 4.9 g Cu(NO 3 ) 2 ∙3H 2 O stirred for 1 h; slowly dropwise added 5.8 g C 3 h 9 OSi∙(CH 4 OSi) n ∙C 3 h 9 Si and 2 drops of ethylenediamine were stirred for 12 h; dried at 80 °C for 6 h; dried at 150 °C for 10 h; treated in a nitrogen atmosphere at 700 °C for 3 h to obtain the catalyst. Wherein the mass content of Cu is 15%, Mo 2 The mass content of C is 19%, SiO 2 The mass content is 66%. The sample has a pore size of 4.3 nm and a pore volume of 170 mm 3 / g, the surface area is 154.3 m 2 / g. The methanol synthesis activity was evaluated with reference to Example 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com