Method and device for extracting collagen fibers by using waste finished leather

A collagen fiber and finished product technology, which is applied in fiber treatment, recycling technology, and decomposition of fiber-containing substances, etc., can solve the problems of fiber quality degradation and other problems, and achieve the effects of large impact force, better opening effect, and improved mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: a kind of method utilizing waste and old finished product leather to extract collagen fiber, mainly comprises the following steps:

[0041] Step S1: crushing, placing the waste finished leather in a dry warehouse, and naturally fermenting for a period of time, so that the connection structure between the coating layer and the collagen fiber layer of the leather is weakened, thereby facilitating subsequent separation. The waste and old finished leather is delivered to the cloth breaker 4 for crushing, so that the large piece of leather is broken into small fragments of leather. Then the fragmented corium is screened, and the fragmented corium with a width greater than 3 mm is re-crushed.

[0042] Step S2: Opening, conveying the fragmented leather with a width of less than 3 mm to the opening machine for opening. Small pieces of fragmented dermis are opened to loosen the collagen fibers on the fragmented dermis and become flocculent, because the coating for...

Embodiment 2

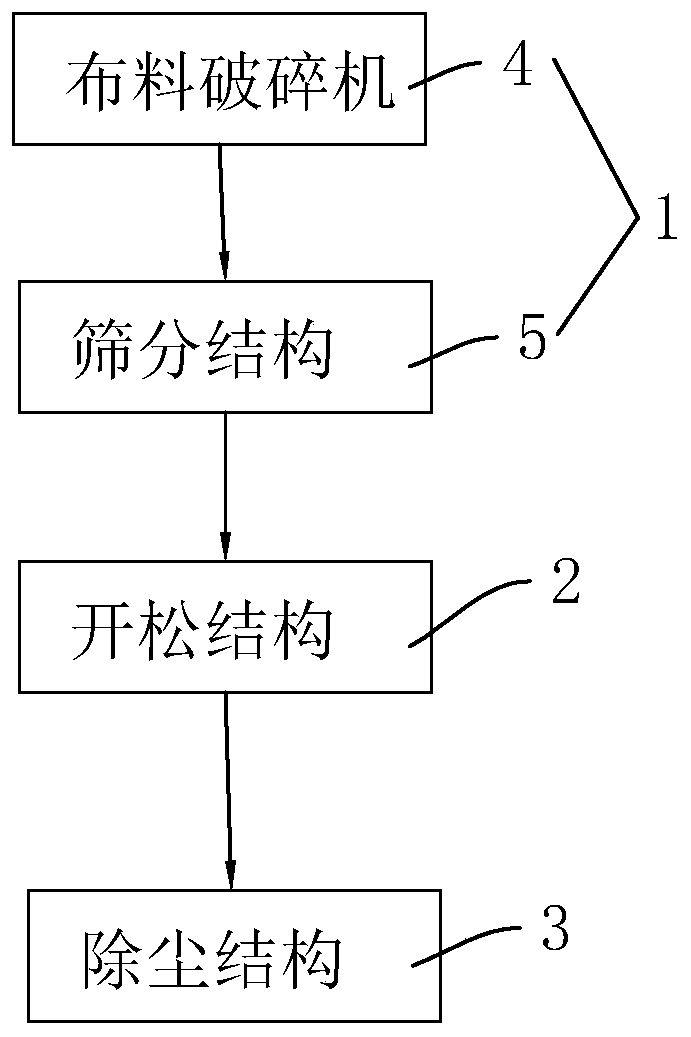

[0045] Embodiment 2: A kind of equipment that utilizes waste and old finished leather to extract collagen fibers, such as figure 1 As shown, it includes a crushing mechanism 1, an opening mechanism and a dust removal mechanism 3 in sequence. Utilize the crushing mechanism 1 to break the large pieces of leftover corium into small fragments of corium, and then use the opening mechanism 2 to open the small fragments of corium, so that the collagen fibers on the fragments of corium are loosened and become flocculent. Because the coating forms dust after crushing and loosening, then the dust and flocculent fibers are transported into the cyclone separator 31, the dust quality is relatively small so that it flows out from the air outlet along with the air, and the flocculent fibers flow out from the cyclone separator The discharge port 213 at the lower end of 31 is discharged, thereby realizing the separation of fibers and coating dust.

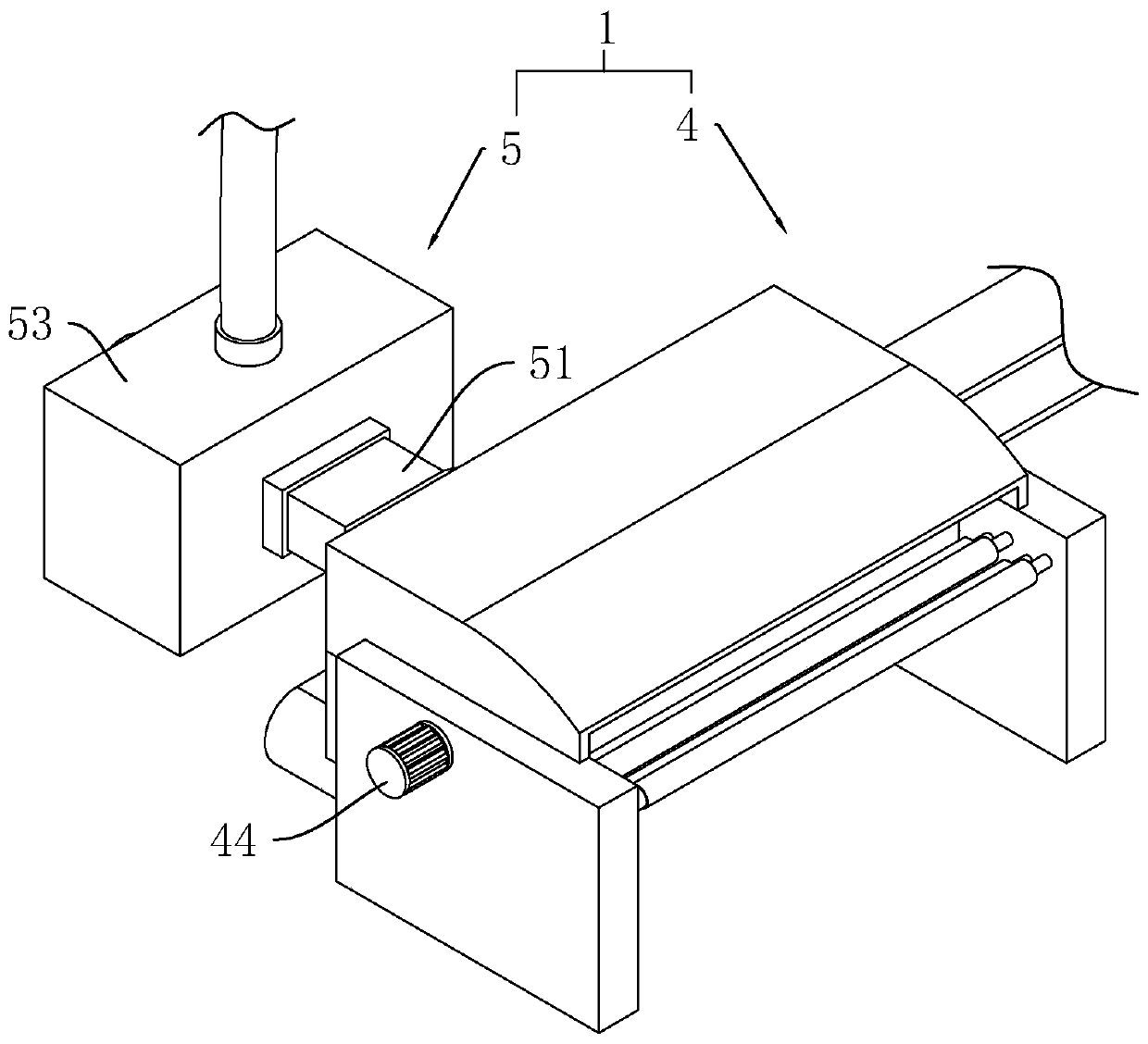

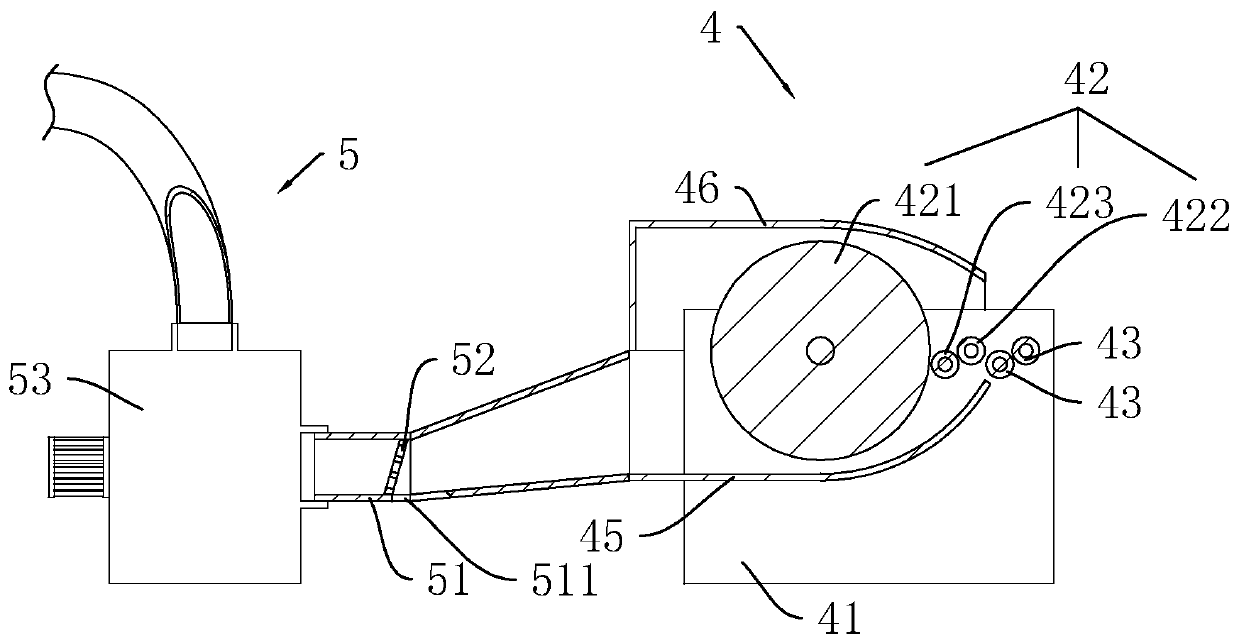

[0046] like figure 2 and image 3 As sho...

Embodiment 3

[0054] Embodiment 3, a production line for extracting collagen fibers by using waste and old finished leather, including a plurality of equipment for extracting collagen fibers by using waste and old finished leather in Example 2 arranged side by side along the longitudinal direction, and then horizontally provided with equipment for extracting collagen fibers The first conveyor belt 61 , the second conveyor belt 62 and the third conveyor belt 63 are connected in series. The first conveyor belt 61 is located below the discharge opening 511 of the connecting pipe 51, and one end of the first conveyor belt 61 in the transmission direction is provided with a vibrating screen machine 64 to remove dust and particles generated during crushing, keep larger fragments of corium, and then remove the larger fragments. The fragmented leather is re-transported to the equipment for extracting collagen fibers from waste finished leather in Example 2 for crushing, opening and dust removal.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com