Coal gangue separation sieve, coal gangue sorting part and coal purification gangue removal machine

A technology for separating sieves and gangue, which is applied in solid separation, separating solids from solids with airflow, and filtering and sieving, and can solve problems such as difficulties in pre-screening operations, mixing gangue, and affecting coal preparation work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

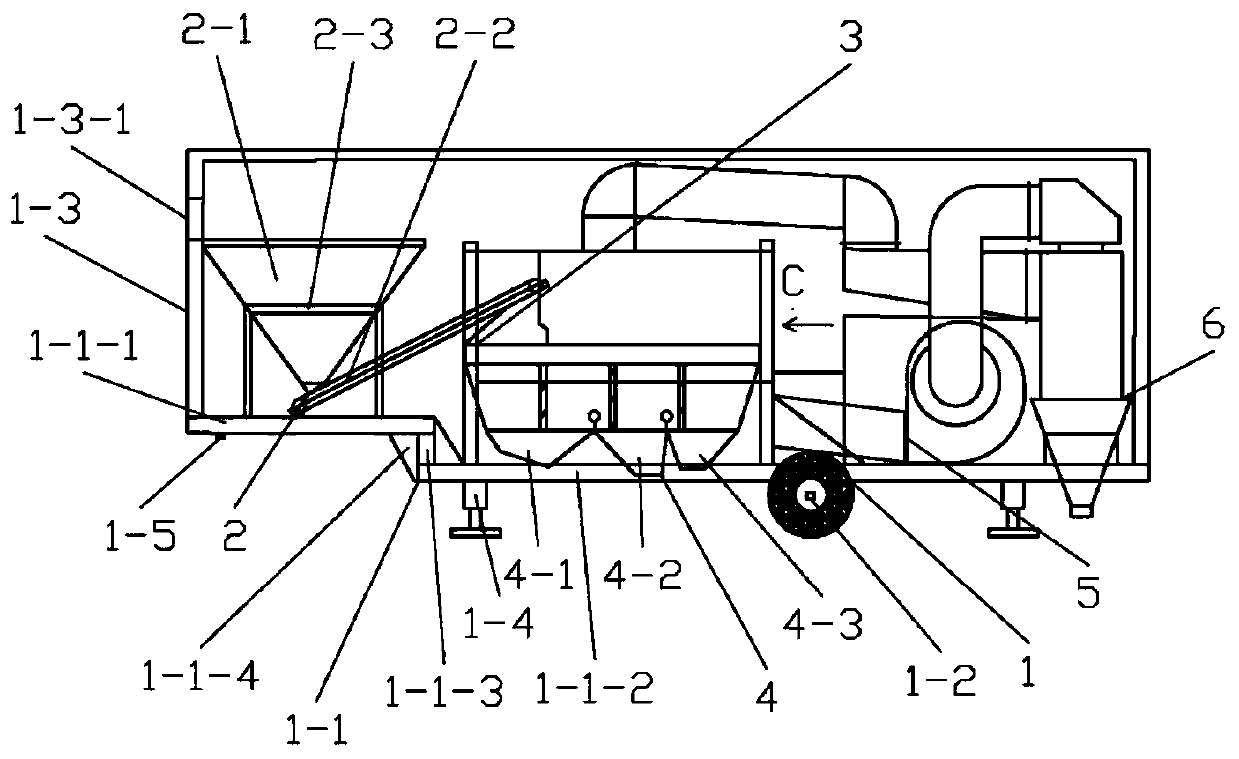

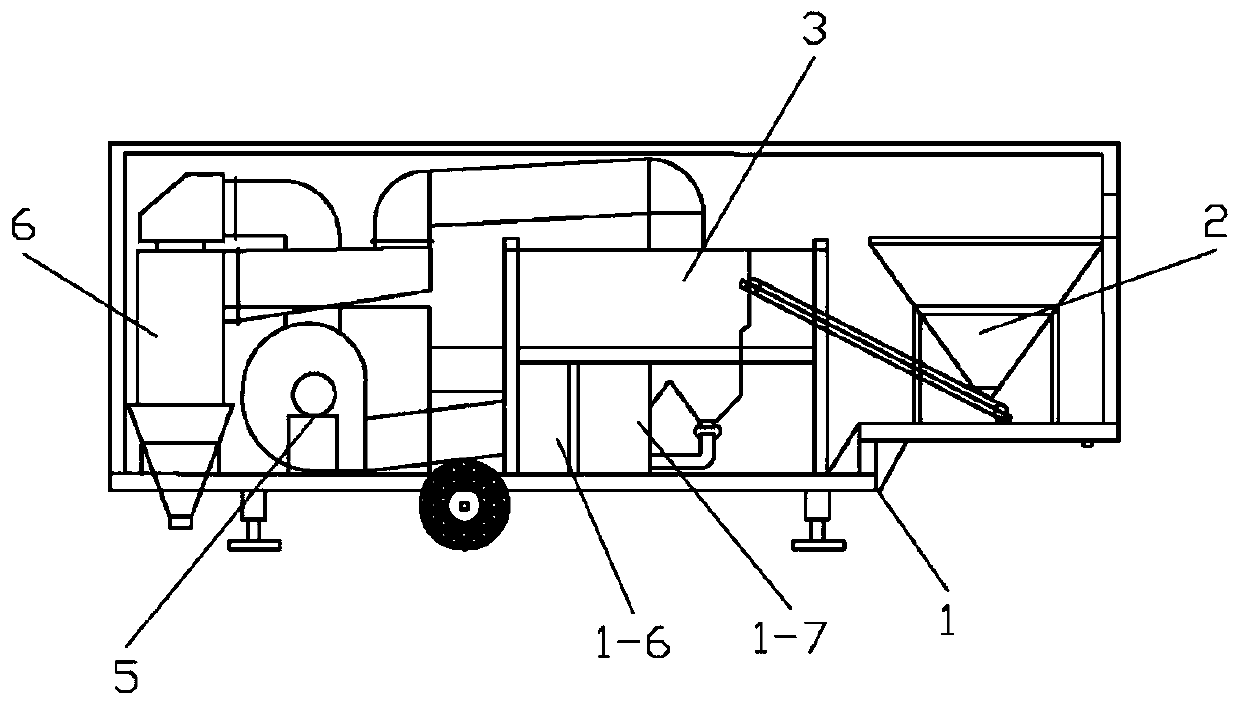

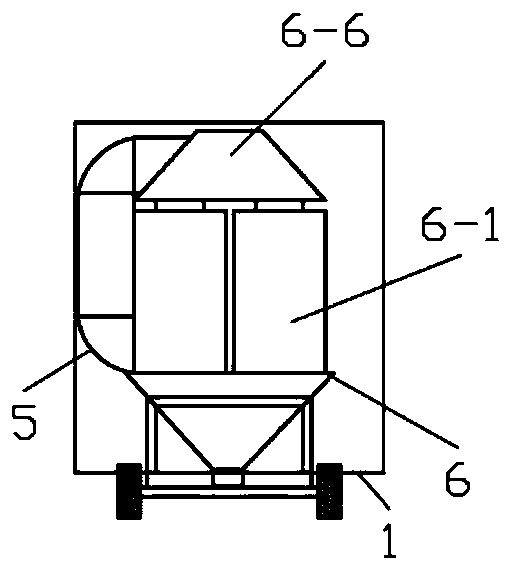

[0199] Such as Figure 7 to Figure 9 As shown, a gangue separation screen, the shape of the bottom plate of the gangue separation screen 3-1 is a right-angled trapezoid, and the high side of the bottom plate of the gangue separation screen 3-1 is provided with an inclined baffle 3-1-5, The angle between the inclined baffle 3-1-5 and the bottom plate of the gangue separation screen 3-1 is an acute angle, and at least one vibration motor 3-1 is arranged on the outside of the inclined baffle 3-1-5. 1-9, the rotation axis of the vibration motor 3-1-9 is perpendicular to the high side of the bottom plate of the gangue separation screen 3-1, and the rotation axis of the vibration motor 3-1-9 is separated from the gangue The angle between the bottom plates of the sieve 3-1 is greater than 0° and less than or equal to 90°. Viewed from the upper end of the rotating shaft of the vibrating motor 3-1-9, the rotating shaft of the vibrating motor 3-1-9 Rotate clockwise, the long base of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com