On-line cutting-off method for special-shaped end of automobile frame cross beam

A technology of end-on-line and automobile frame, which is applied in the direction of vehicle parts, transportation and packaging, etc., can solve the problems of reducing the processing accuracy of the beam, prolonging the processing process of the beam, and increasing the processing cost, so as to shorten the processing process, avoid errors, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

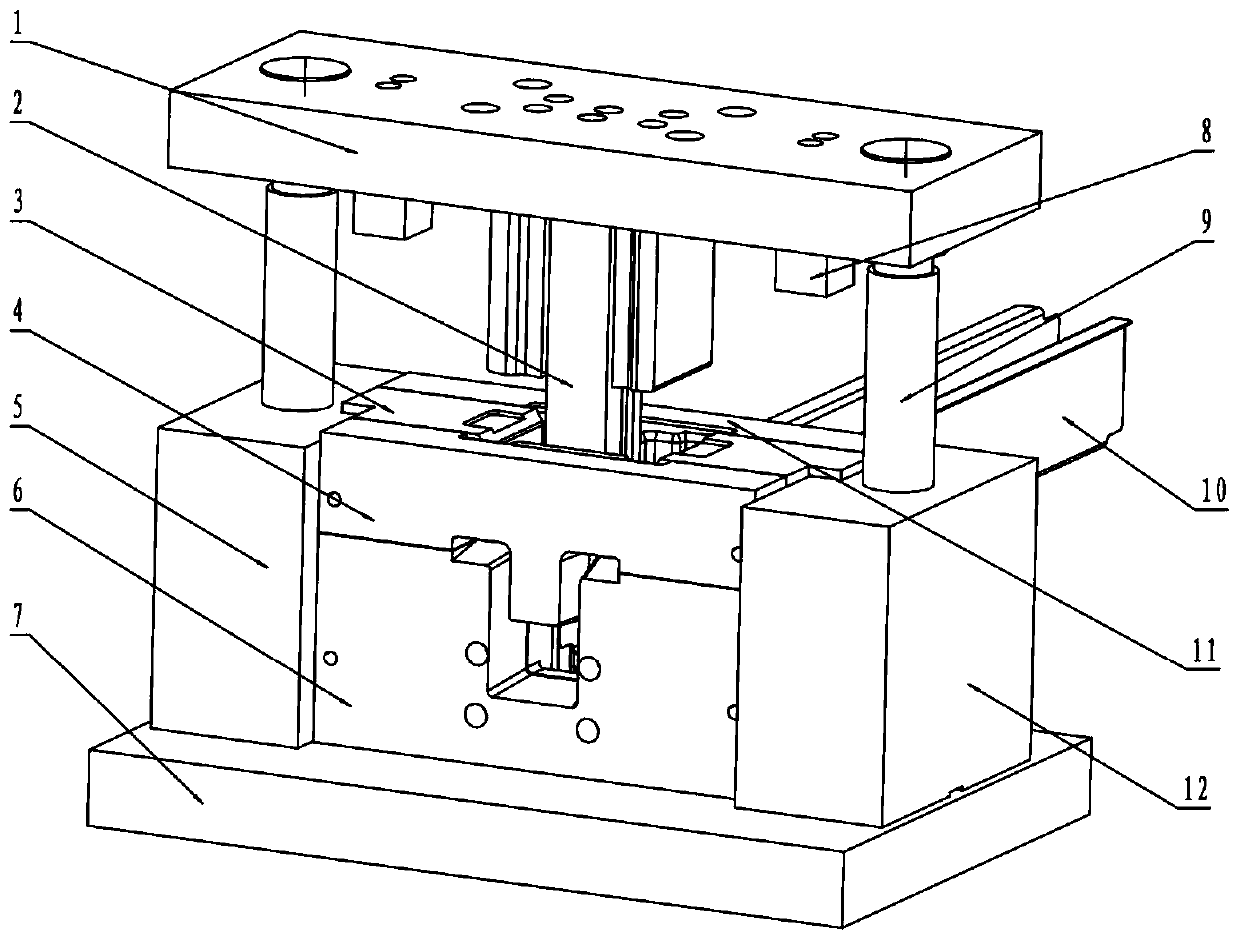

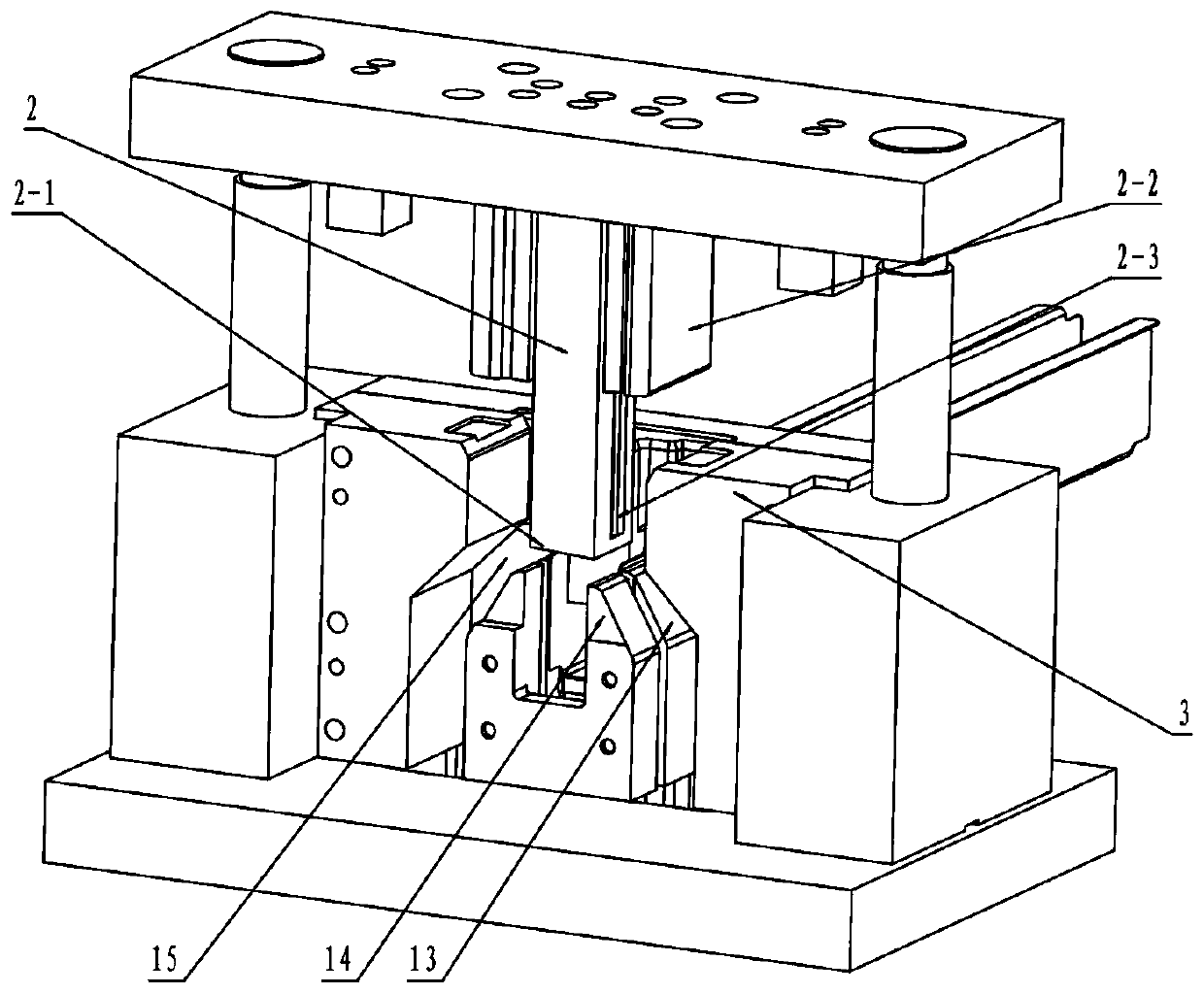

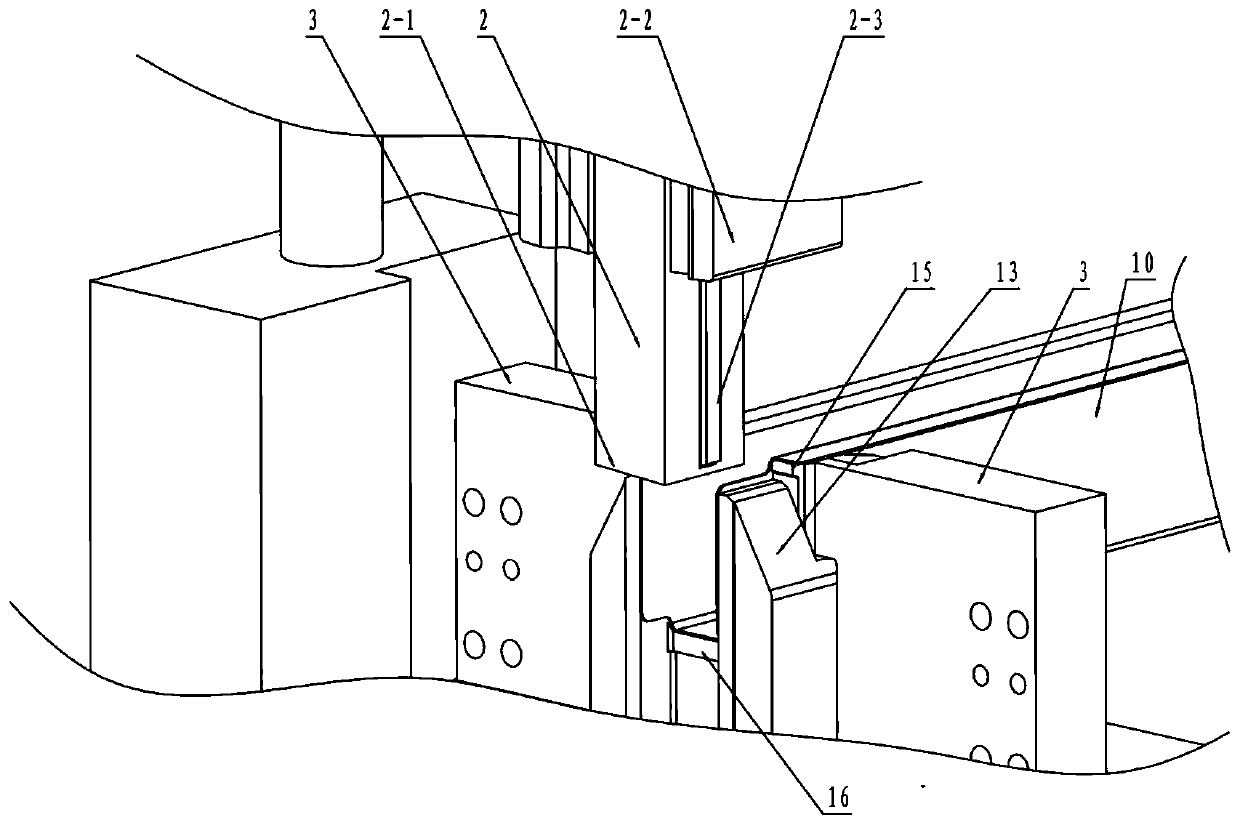

Image

Examples

Embodiment Construction

[0027] The inventive method comprises the steps: Figure 9-Figure 11 , first punch out the process slots in advance for the material strips for making the automobile frame beams, so that the material strips can be cut off at the process slots after roll forming. According to the requirements of the forming surface of the special-shaped end and the length of the product, four process slots and edge gaps are pre-punched at the cutting position of the material strip 17. The four process slots include two symmetrically arranged The bottom edge slot 17-3 and two symmetrically arranged flanging slots 17-2, the bottom edge slot is located at the bend of the bottom surface of the product strip after molding, and the flanging slot is located at the formed product strip At the bending position of the upper flanging, two symmetrically arranged edge notches 17-1 correspond to the flanging slots respectively. For the convenience of vertical punching, grooves are provided in the flange slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com