Waste tire breaker convenient to clean

A technology for crushers and waste tires, which is applied in grain processing, mechanical material recovery, filter screens, etc., can solve the problems of affecting the service life of the crusher, raising the water storage cavity, and being easy to get stuck on the screen mesh, etc. The effect of improving crushing effect, increasing reliability and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

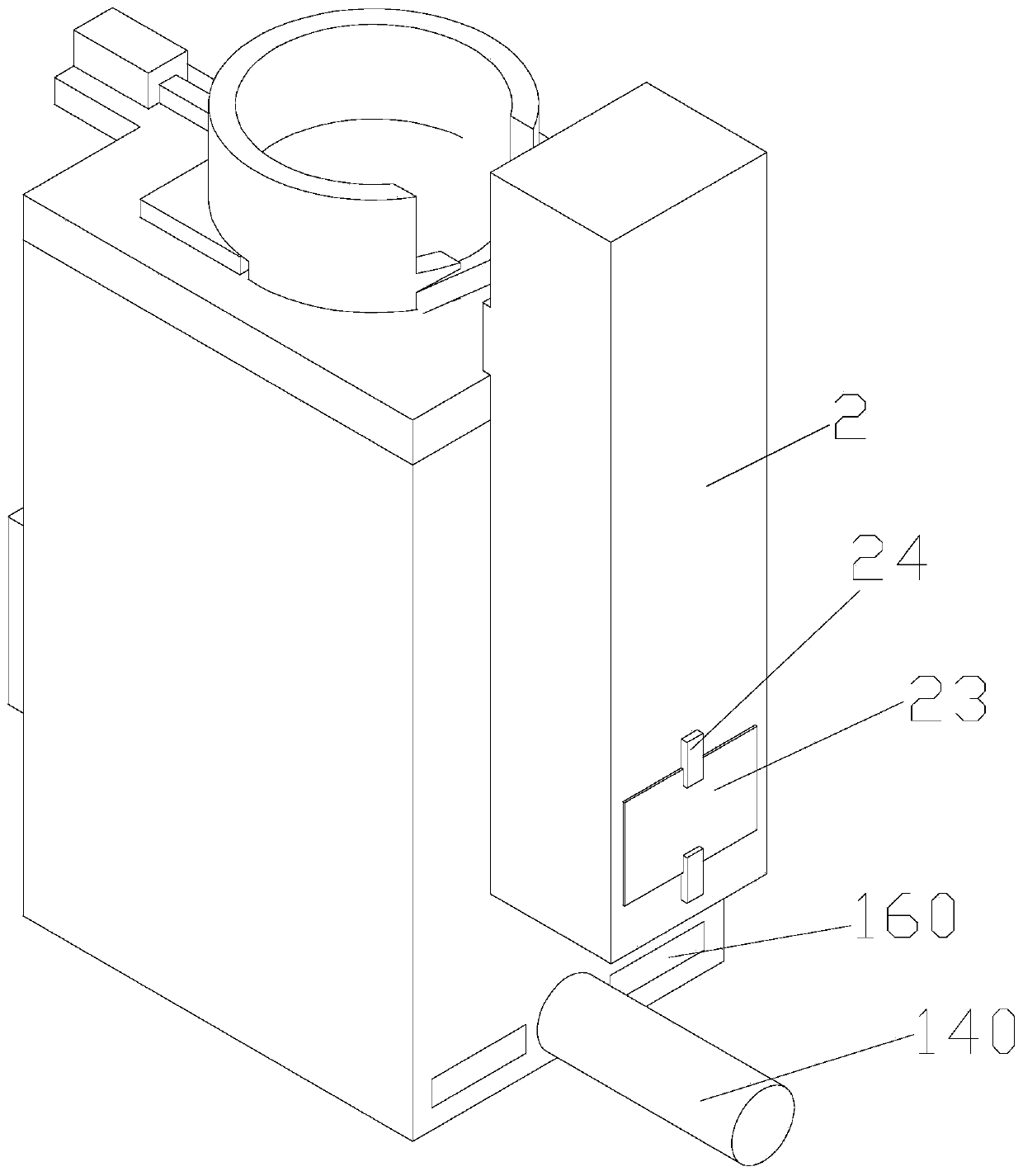

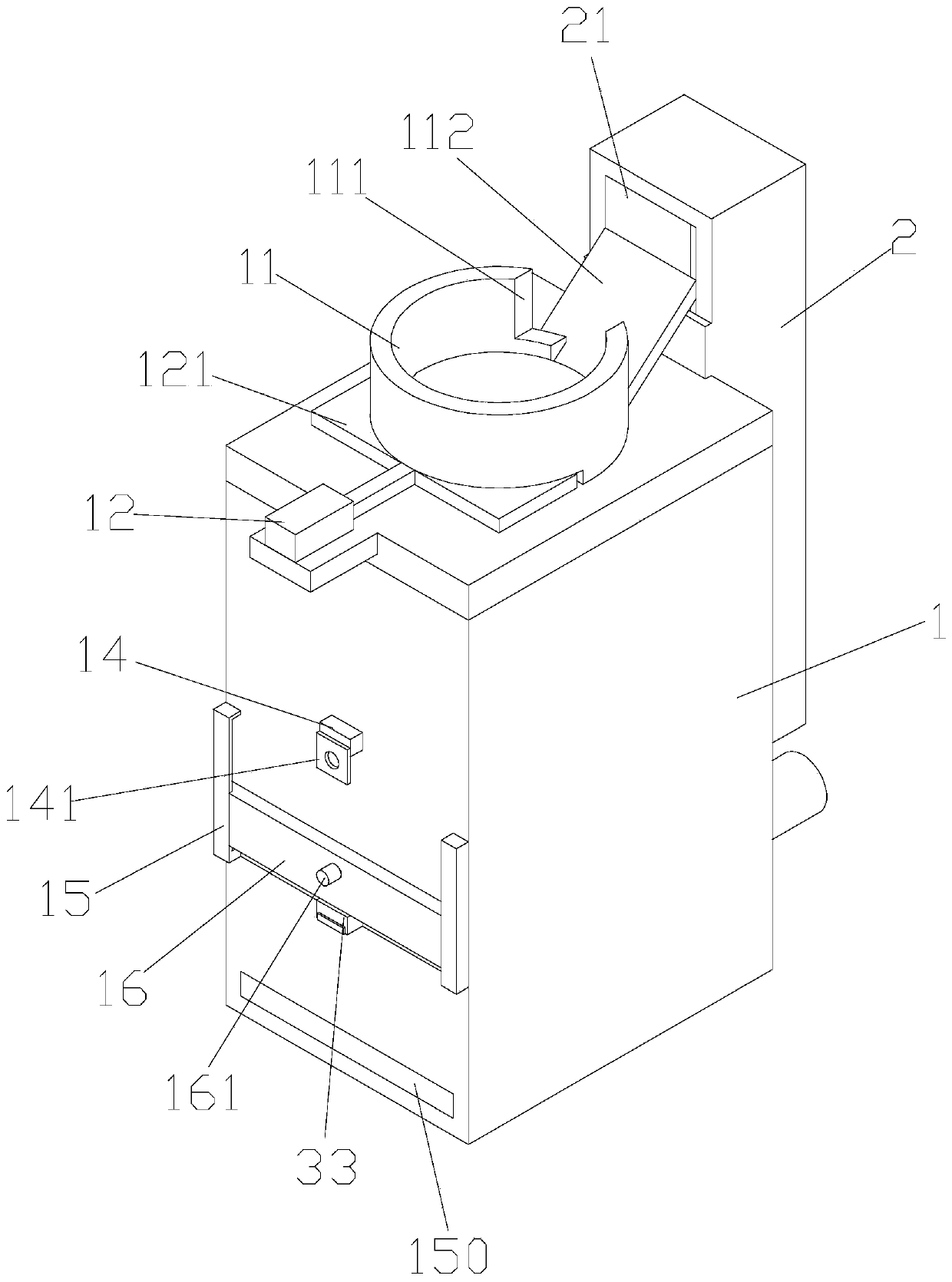

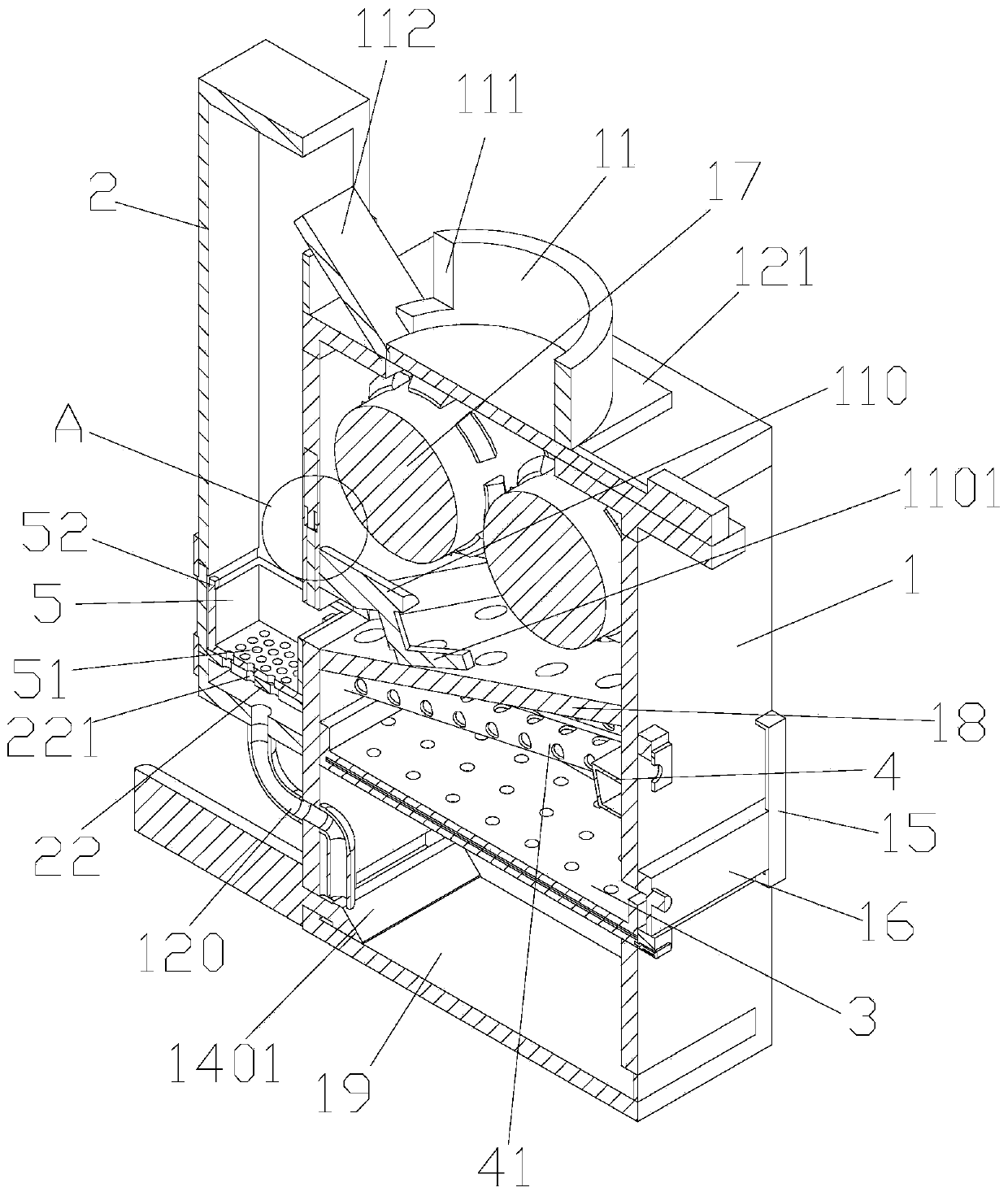

[0022] Such as Figure 1-10 As shown, a waste tire shredder that is easy to clean includes a box body 1, a crushing roller 17 arranged in the box body 1, and a sieve plate 18 arranged below the crushing roller 17, and the crushing rollers are two groups facing each other. The set of rollers, two sets of rollers rotate relatively, which is convenient for crushing waste tires; the top of the box body 1 is provided with a feeding port, and the top of the box body 1 is provided with a feeding port that matches the feeding port. The feed pipe 11, the box body 1 is provided with a material receiving plate 3, the material receiving plate 3 is arranged below the sieve plate 18, and the material receiving plate is provided with a baffle plate 31 to facilitate the collection of rubber blocks and prevent The rubber block falls from the receiving plate; the box body 1 is provided with a spraying device, and the spraying device is arranged below the sieve plate 18, and the side wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com