Mechanical processing waste chip treatment device

A processing device and mechanical processing technology, applied in metal processing equipment, water/sewage multi-stage treatment, metal processing machinery parts, etc., can solve the problems of incomplete separation of waste chips and cutting fluid, difficulty in recycling polluted environment, etc., and achieve structural Ingenious, thorough and efficient separation, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

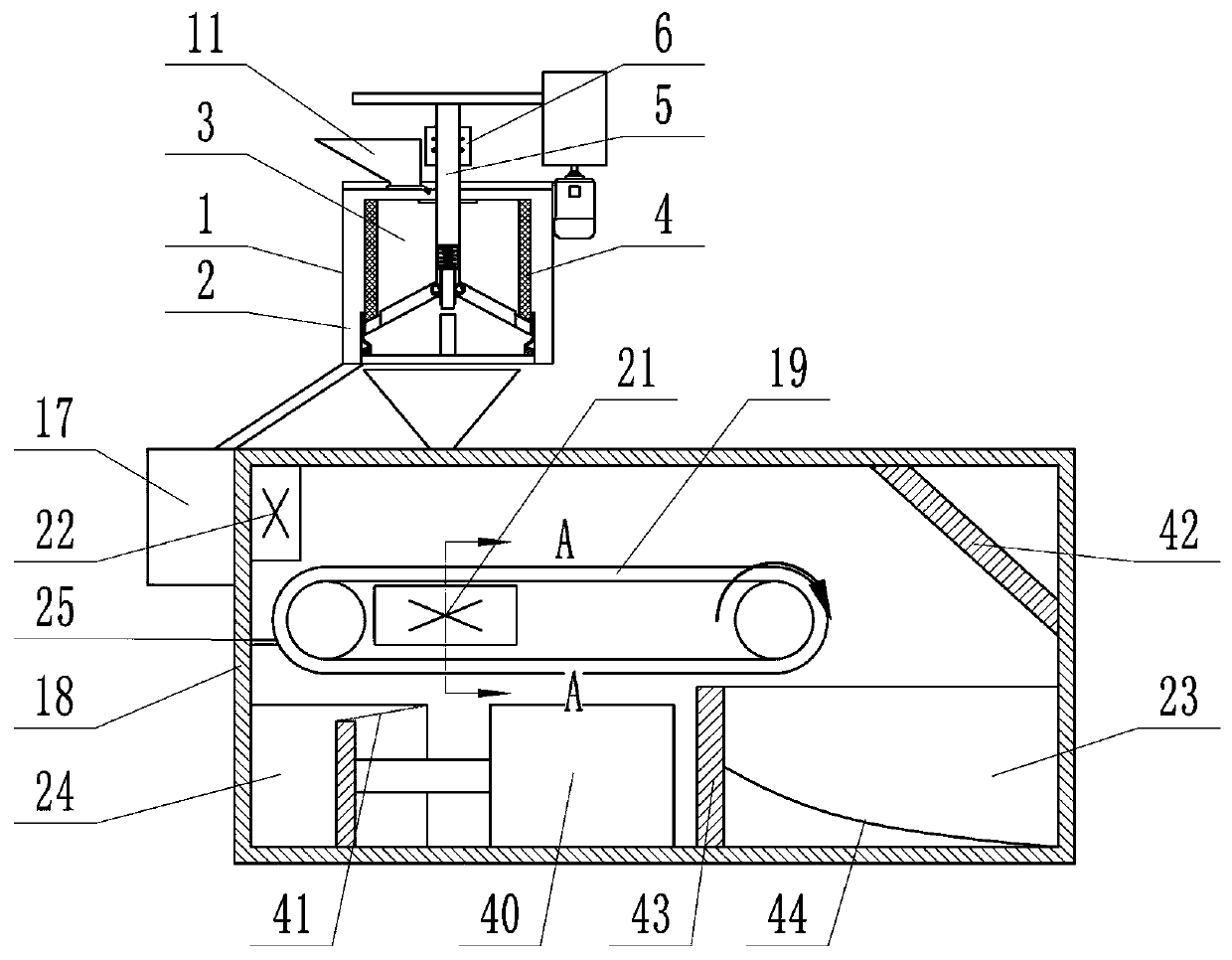

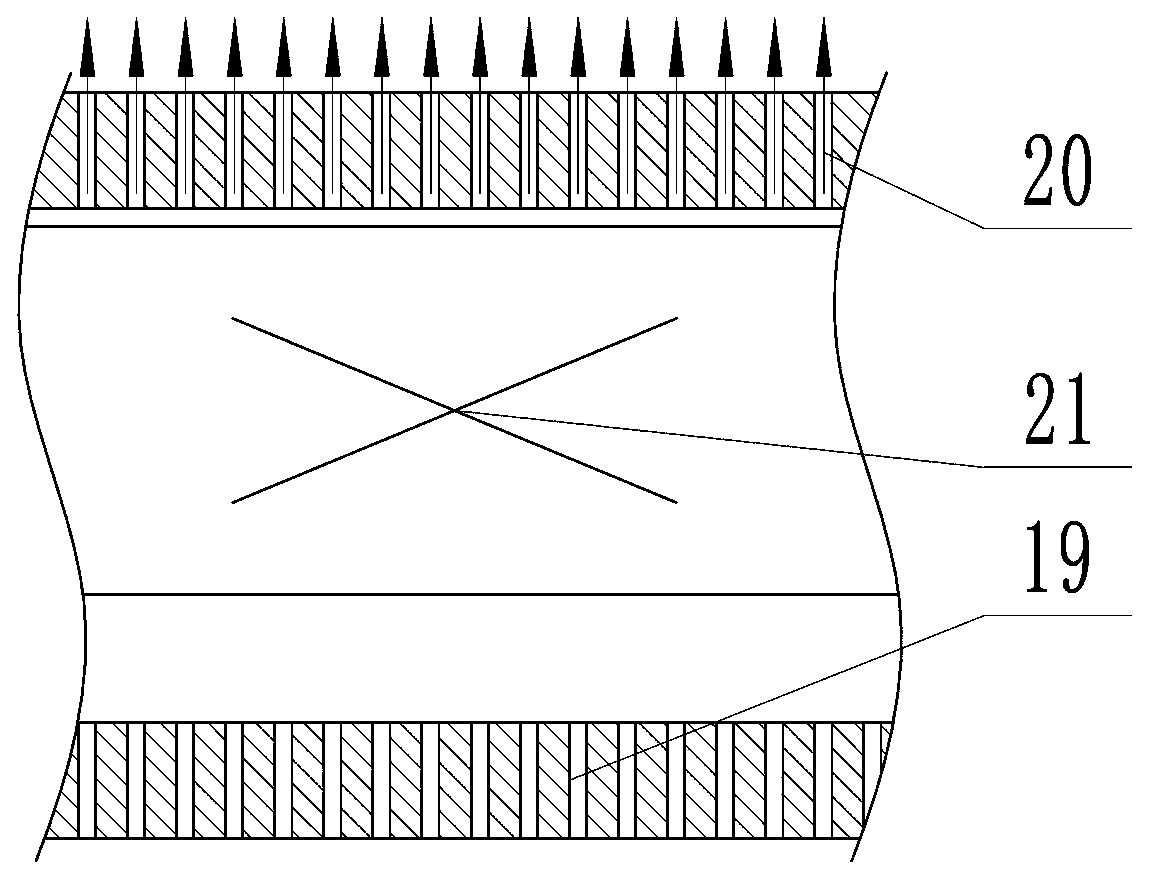

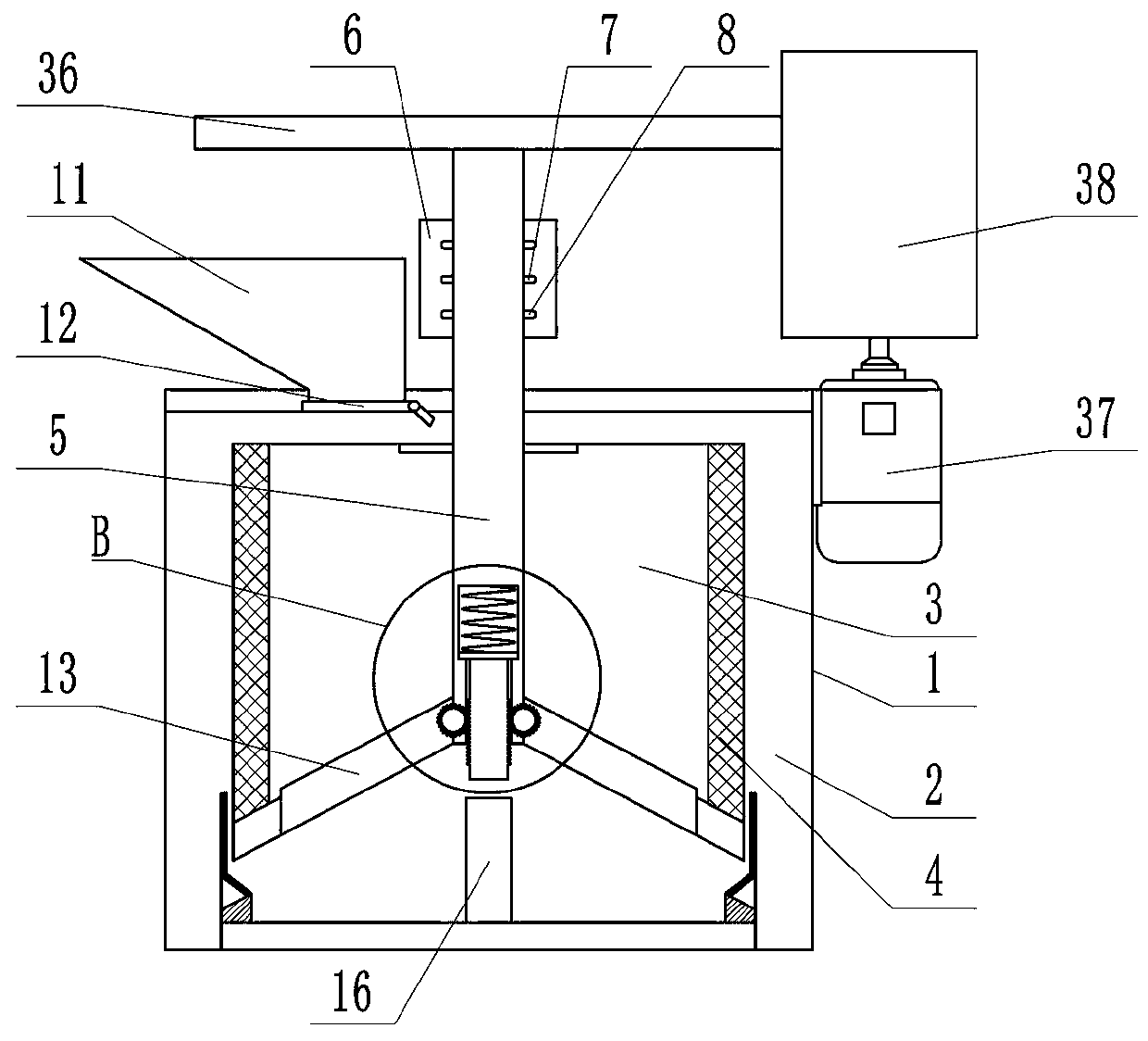

[0021] The following is attached Figure 1 to Figure 13 The specific implementation manner of the present invention will be described in further detail.

[0022] Depend on Figure 1 to Figure 13 It can be seen that a mechanical processing waste treatment device includes a solid-liquid separation bucket and a sundry separation box 18. The solid-liquid separation bucket includes a liquid collection bucket 1 and a dump bucket 3, and the dump bucket 3 is movable and fixed inside the liquid collection bucket 1. The outer wall of the barrel 3 is the first filter screen 4, the rotating shaft 5 of the throwing barrel 3 protrudes from the top of the liquid collecting barrel 1, the outside of the rotating shaft 5 is fixed with a fixed block 6, and the fixed block 6 is provided with a spiral groove, and the rotating shaft 5 protrudes from an insertion screw. The positioning rod 7 in the groove, the positioning rod 7 slides in the spiral groove all the time when the bucket 3 rotates, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com