Modified adhesive for paper cultural relics and preparation method of modified adhesive

A technology for paper cultural relics and adhesives, applied in the direction of adhesive types, amylose/amylopectin adhesives, adhesives, etc., can solve the problem of easy hydrolysis, acidification, ratio and performance instability of adhesives and other problems to achieve a good feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

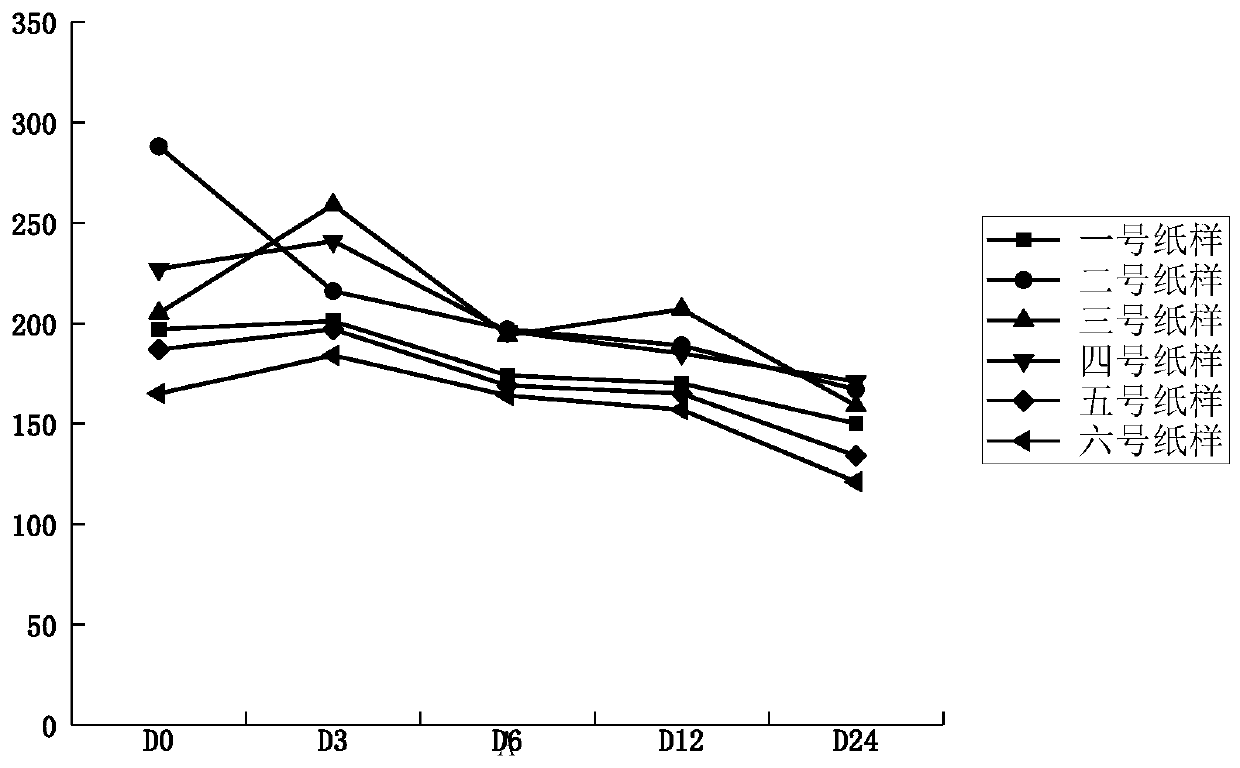

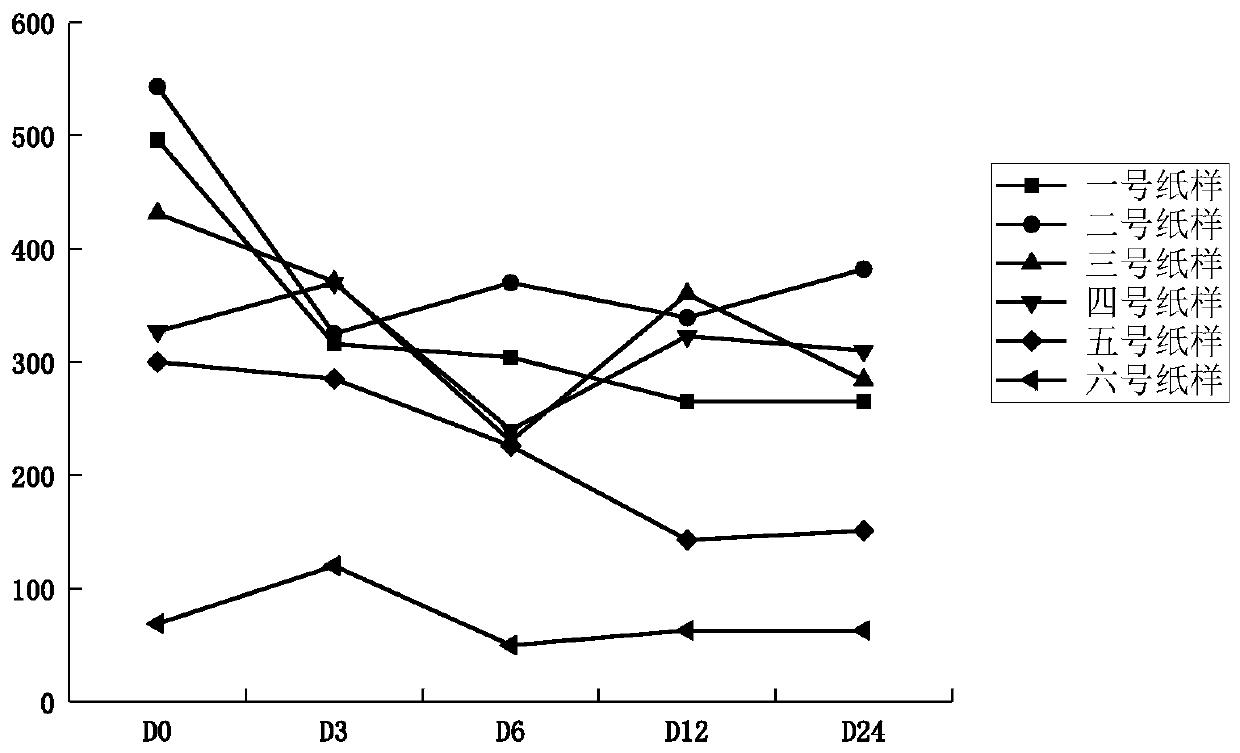

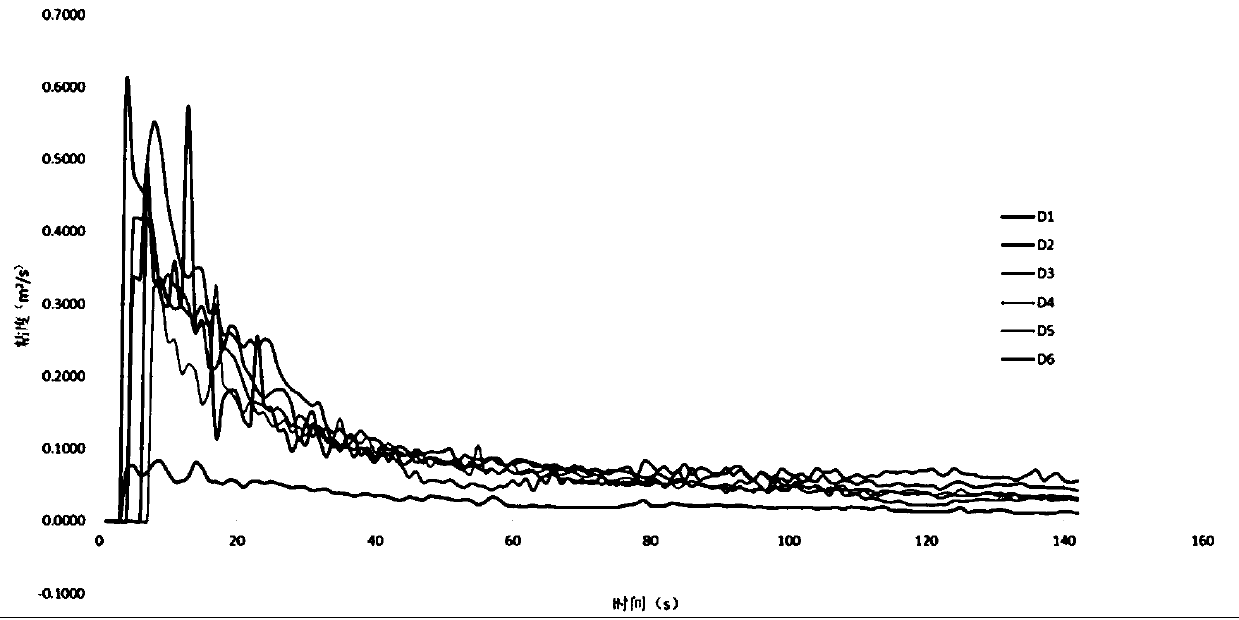

[0044] Example 1: Discussion on the preparation process of modified adhesives containing additives in different proportions and tests on the pH, viscosity, peeling degree, mildew resistance, and practical application effects of the adhesive

[0045] 1. Experimental materials and instruments: wheat starch (Baihe brand); ultrapure water; additives; rotary stirring heater (lesavcier); Clean PH30 portable pH value tester; viscosity meter (RST rheometer); automatic tensile tester).

[0046] 2. Preparation of modified adhesive

[0047] Through literature review, investigation and interviews, we learned about the practical experience of professionals who have been engaged in the protection of paper cultural relics for many years. At the same time, combined with multiple process tests, it was initially determined that the mass ratio of starch and ultrapure water was 1:5, and heated in a rotating stirring heater. Prepare for 30 minutes to completely gelatinize the starch in the adhesi...

Embodiment 2

[0077] Embodiment 2: performance test of modified adhesive coated rice paper

[0078] 1. Experimental materials and instruments: wheat starch (Baihe brand); ultrapure water; additives (compounds that can react with hydroxyl, carboxyl and other groups); cotton four-foot cotton rice paper (Wangliuji brand); Refractometer (MIT); Horizontal Tensile Tester (TMI); Tear Tester (Tinius&Olsen); Dynamic Contact Angle Tester (DAT); Pure Water Tester (Elix3); Portable pH Tester (Clean PH30); Portable Colorimeter (HPG-2132); Constant temperature and humidity test chamber (RMF-115).

[0079] 2. Preparation of modified adhesive

[0080] Using the preparation method in Example 1, sample Nos. 1-6 adhesives were obtained.

[0081] 3. Preparation of coated rice paper samples

[0082] 1) Dilute No. 1-6 adhesives to 50% concentration respectively. Use a pad pen to evenly coat one side of the cotton four-foot cotton continuous rice paper, collapse it on the table, take it off after the rice pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com