Sensitive thin film in thin film pressure sensor and its manufacturing method and application

A thin film pressure, sensitive thin film technology, applied in the measurement of the property force of piezoelectric resistance materials, fluid pressure measurement by changing ohmic resistance, instruments, etc., can solve the problem of large resistance temperature coefficient, poor corrosion resistance, thin film shedding and other problems, to achieve high sheet resistance, large strain factor, and reduce the temperature coefficient of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

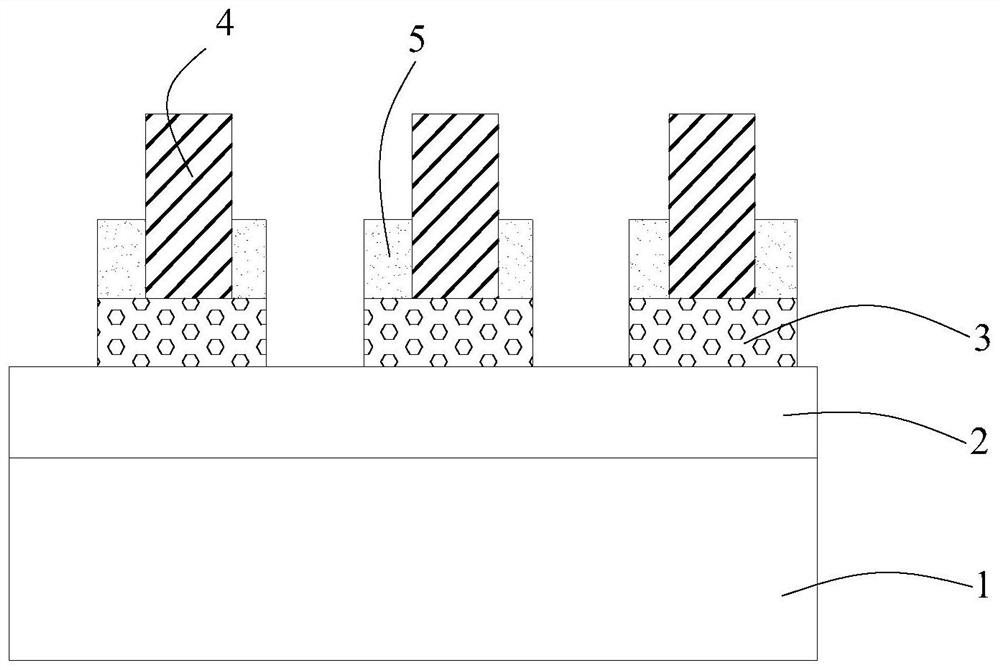

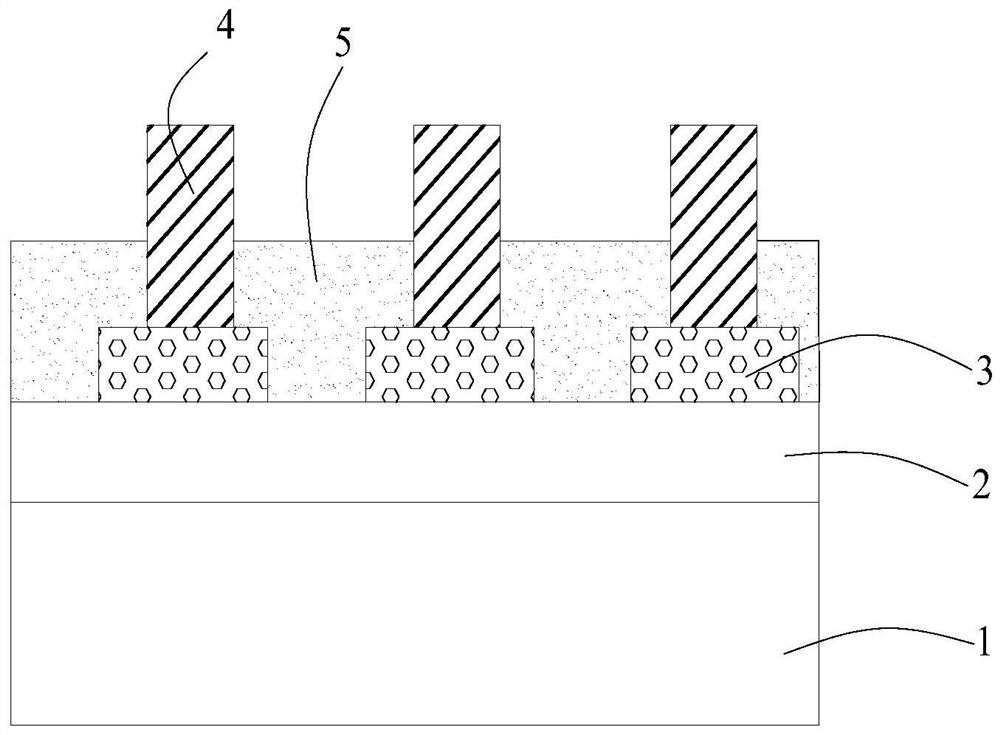

[0053] The present embodiment provides a kind of sensitive thin film in thin film pressure sensor, and its material is (Ni 0.8 Cr 0.2 ) 0.85 Ta 0.1 N 0.05 .

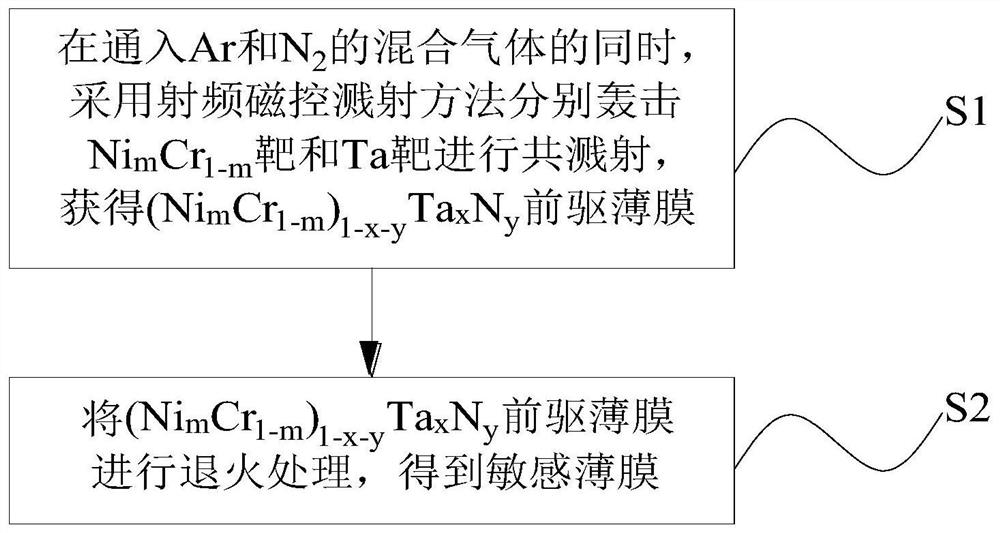

[0054] The above-mentioned sensitive film in the present embodiment adopts following method to prepare: (1) adopts radio frequency magnetron sputtering method to bombard Ni 0.8 Cr 0.2 target and Ta target, while sputtering, pass Ar gas and N into the reaction chamber 2 The mixed gas, control N 2 The flow rate is 5 sccm, the Ar flow rate is 100 sccm, and the background vacuum is 2×10 -4 , the deposition power is 300W, the deposition time is 2000s, the deposition temperature is 100°C, and the deposition pressure is 0.6Pa. According to the test results of secondary ion mass spectrometry (SIMS), it was confirmed that (Ni 0.8 Cr 0.2 ) 0.85 Ta 0.1 N 0.05 precursor film. (2) will (Ni 0.8 Cr 0.2 ) 0.85 Ta 0.1 N 0.05 Precursor film in N 2 Under the atmosphere, control the heating rate of 10°C / min to raise the ...

Embodiment 2

[0061] The present embodiment provides a kind of sensitive thin film in thin film pressure sensor, and its material is (Ni 0.8 Cr 0.2 ) 0.8 Ta 0.1 N 0.1 .

[0062] The above-mentioned sensitive film in the present embodiment adopts following method to prepare: (1) adopts radio frequency magnetron sputtering method to bombard Ni 0.8 Cr 0.2 target and Ta target, while sputtering, pass Ar gas and N into the reaction chamber 2 The mixed gas, control N 2 The flow rate is 28sccm, the Ar flow rate is 92sccm, and the background vacuum is 2×10 -4 , the deposition power is 100W, the deposition time is 2000s, the deposition temperature is 100°C, and the deposition pressure is 3Pa. According to the test results of secondary ion mass spectrometry (SIMS), it was confirmed that (Ni 0.8 Cr 0.2 ) 0.8 Ta 0.1 N 0.1 precursor film. (2) will (Ni 0.8 Cr 0.2 ) 0.8 Ta 0.1 N 0.1 Precursor film in N 2 Under the atmosphere, the temperature was raised to 900° C. at a controlled rate o...

Embodiment 3

[0068] The present embodiment provides a kind of sensitive thin film in thin film pressure sensor, and its material is (Ni 0.5 Cr 0.5 ) 0.75 Ta 0.12 N 0.13 .

[0069] The above-mentioned sensitive film in the present embodiment adopts following method to prepare: (1) adopts radio frequency magnetron sputtering method to bombard Ni 0.5 Cr 0.5 target and Ta target, while sputtering, pass Ar gas and N into the reaction chamber 2 The mixed gas, control N 2 The flow rate is 10sccm, the Ar flow rate is 70sccm, and the background vacuum is 5×10 -5 , the deposition power is 200W, the deposition time is 1000s, the deposition temperature is 300°C, and the deposition pressure is 3Pa. According to the test results of secondary ion mass spectrometry (SIMS), it was confirmed that (Ni 0.5 Cr 0.5 ) 0.75 Ta 0.12 N 0.13 precursor film. (2) will (Ni 0.5 Cr 0.5 ) 0.75 Ta 0.12 N 0.13 Precursor film in N 2 Under the atmosphere, control the heating rate of 30°C / min to raise the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com