A device and method based on continuous anode aluminum electrolysis

An electrolysis device and anode aluminum technology, applied in the field of aluminum electrolysis, can solve problems such as poor anode electrical contact and difficult collection of smoke, achieve uniform current distribution, reduce anode voltage drop, and prevent smoke leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

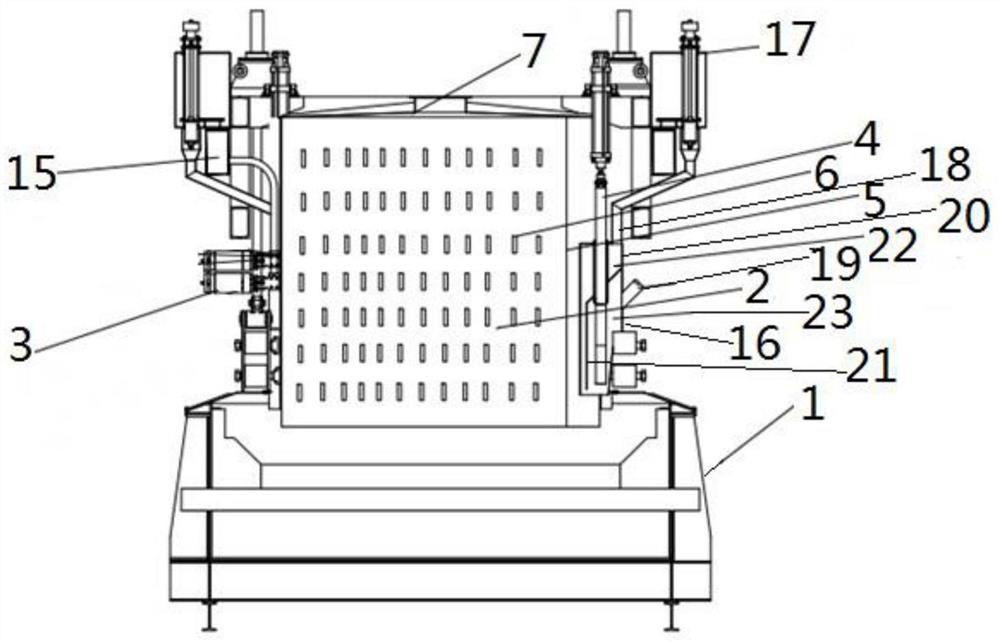

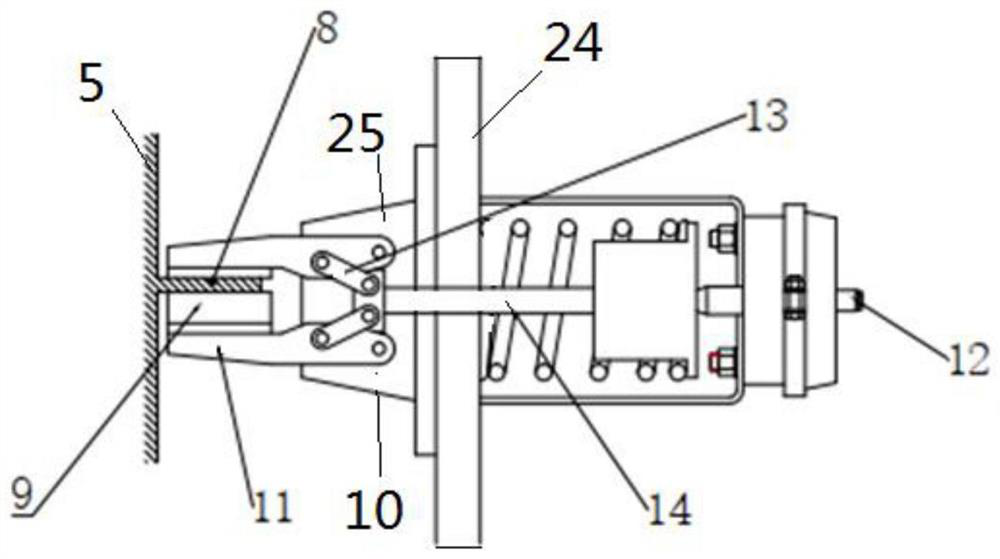

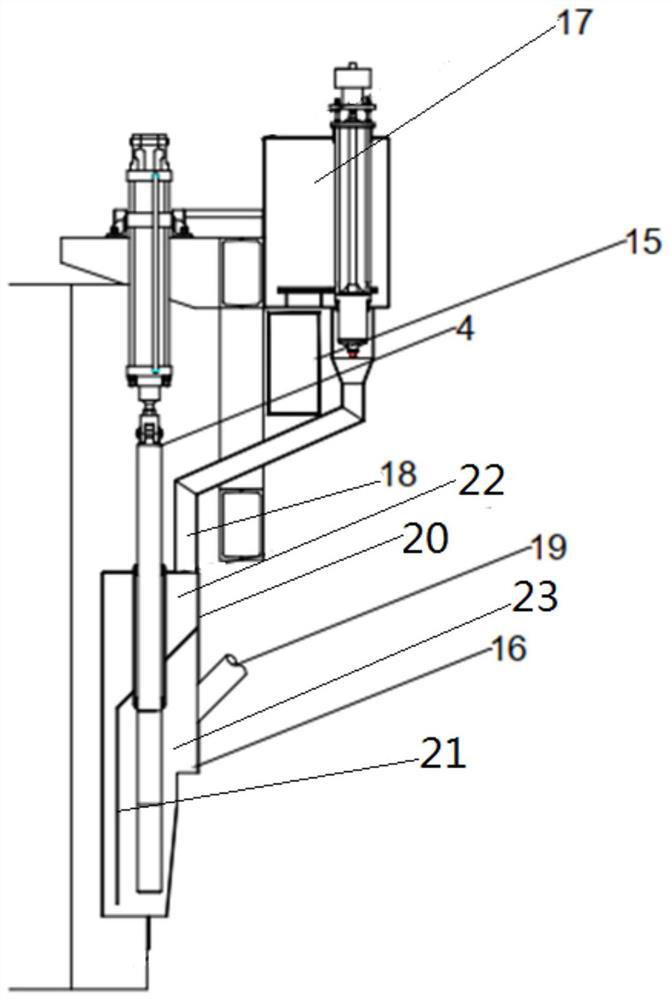

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] Such as Figure 1-4 As shown, an aluminum electrolysis device based on continuous anodes includes: an aluminum electrolysis cell 1, an anode structure 2, a power feeding device 3, and a shelling and unloading mechanism 4;

[0022] The anode structure is arranged above the aluminum electrolytic cell 1, and the anode structure includes the anode frame 5 and the anode, and the anode is arranged in the anode frame; the anode frame is a consumable frame, and the frame can be formed, calcined carbon material or the original Made of aluminum or aluminum alloy materials that have no influence on the quality of aluminum, the height of the anode frame is 0.5-4m;

[0023] There are several conductors 6 inside the anode frame. The function of the conductors is to ensure that the current is evenly distributed in the anode, and the anode is lowered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com