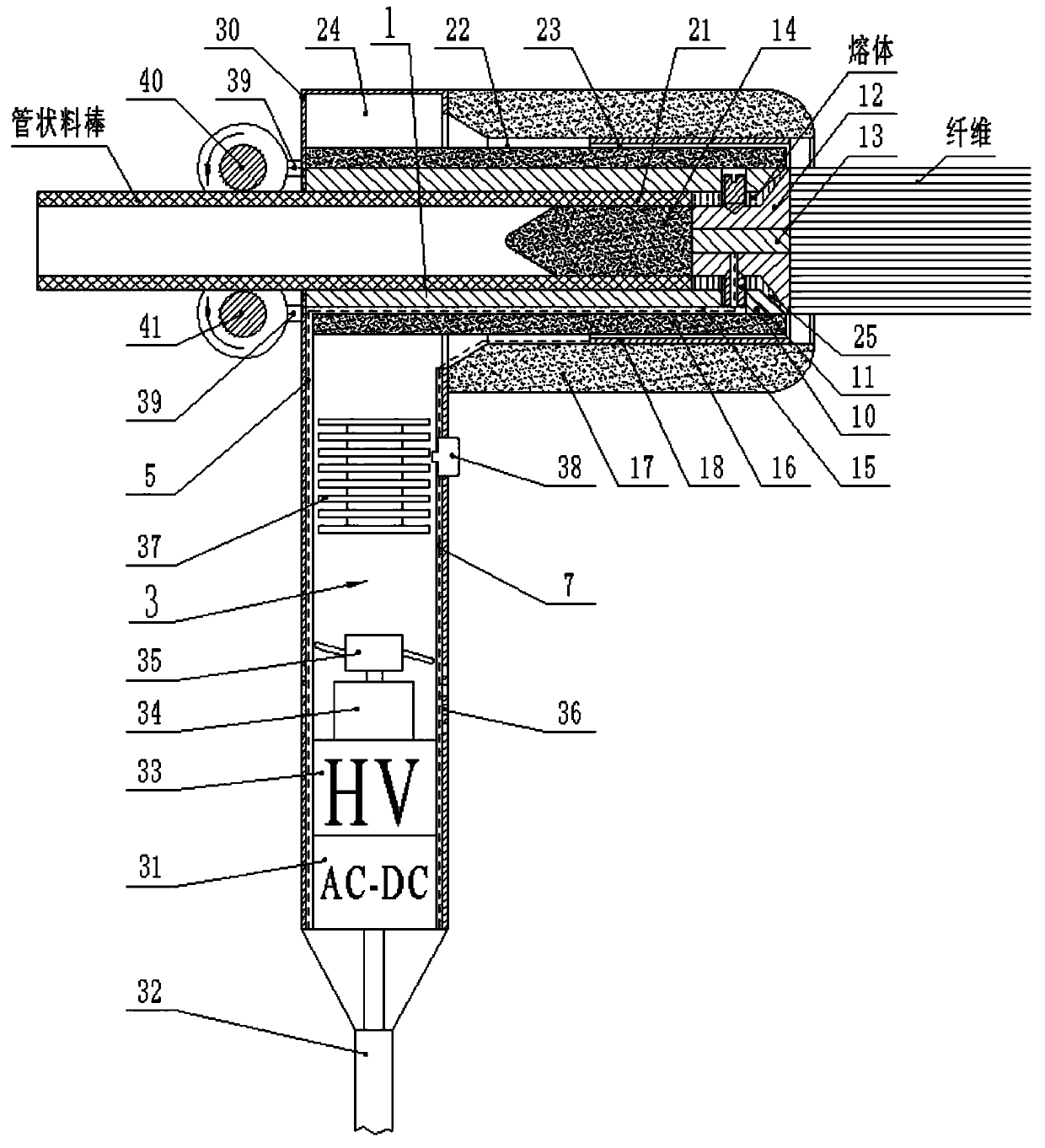

Portable melt electrospinning device

A melt electrospinning, portable technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of complicated operation, large volume, and limiting the development of electrospinning technology, and protect personnel safety , protect the safety of personnel and equipment, and facilitate storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

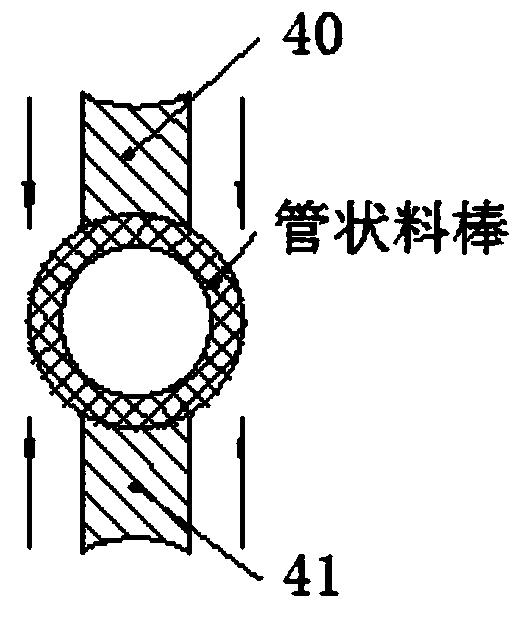

[0013] The main structure of the portable melt electrospinning device involved in this embodiment is composed of a spinning part 1, a handle part 3, a low-voltage wire 5 and a high-voltage wire 7; the main structure of the spinning part 1 includes a sleeve 10, a top wire 11, Spinning nozzle 12, heating rod 13, guide post 14, wire groove 15, inner isolation protective cover 16, outer isolation protective cover 17 and high-voltage electrode 18; the sleeve 10 of tubular structure passes through three top wires 11 arranged at equal intervals Connected with the spinning nozzle 12, one of the top wires 11 is a hollow structure, the center of the spinning nozzle 12 is provided with a cylindrical heating rod 13, and the rear ends of the spinning nozzle 12 and the heating rod 13 are arranged inside the sleeve 10 The guide post 14 is connected, the lower part of the outer surface of the sleeve 10 is provided with a wire groove 15, the outer periphery of the sleeve 10 is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com