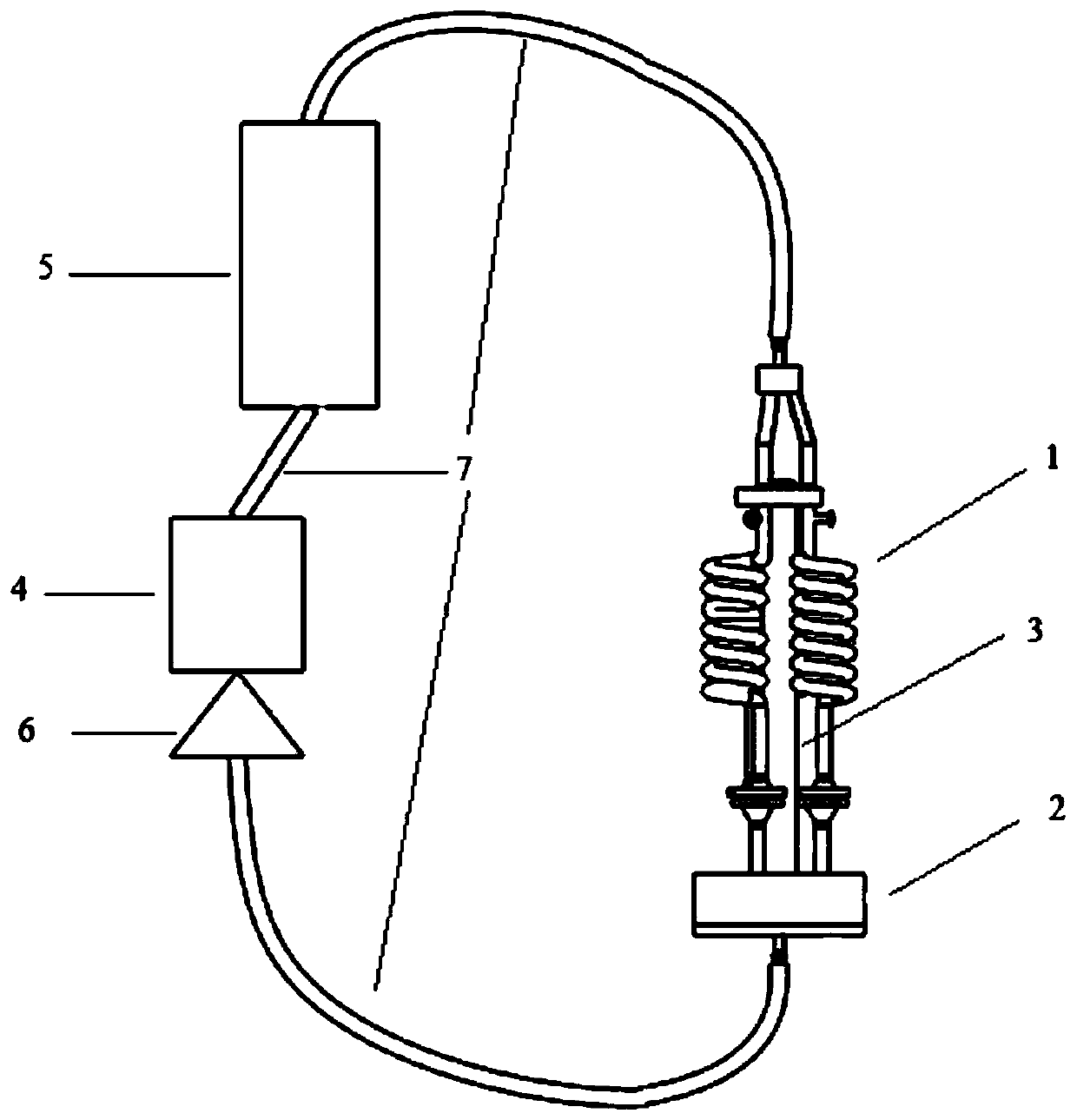

Refrigerating device with extensible structure and manufacturing method thereof

A technology of refrigerators and refrigeration tubes, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of small range of refrigeration capacity and poor space adaptability, and achieve increased adaptability, easy implementation, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

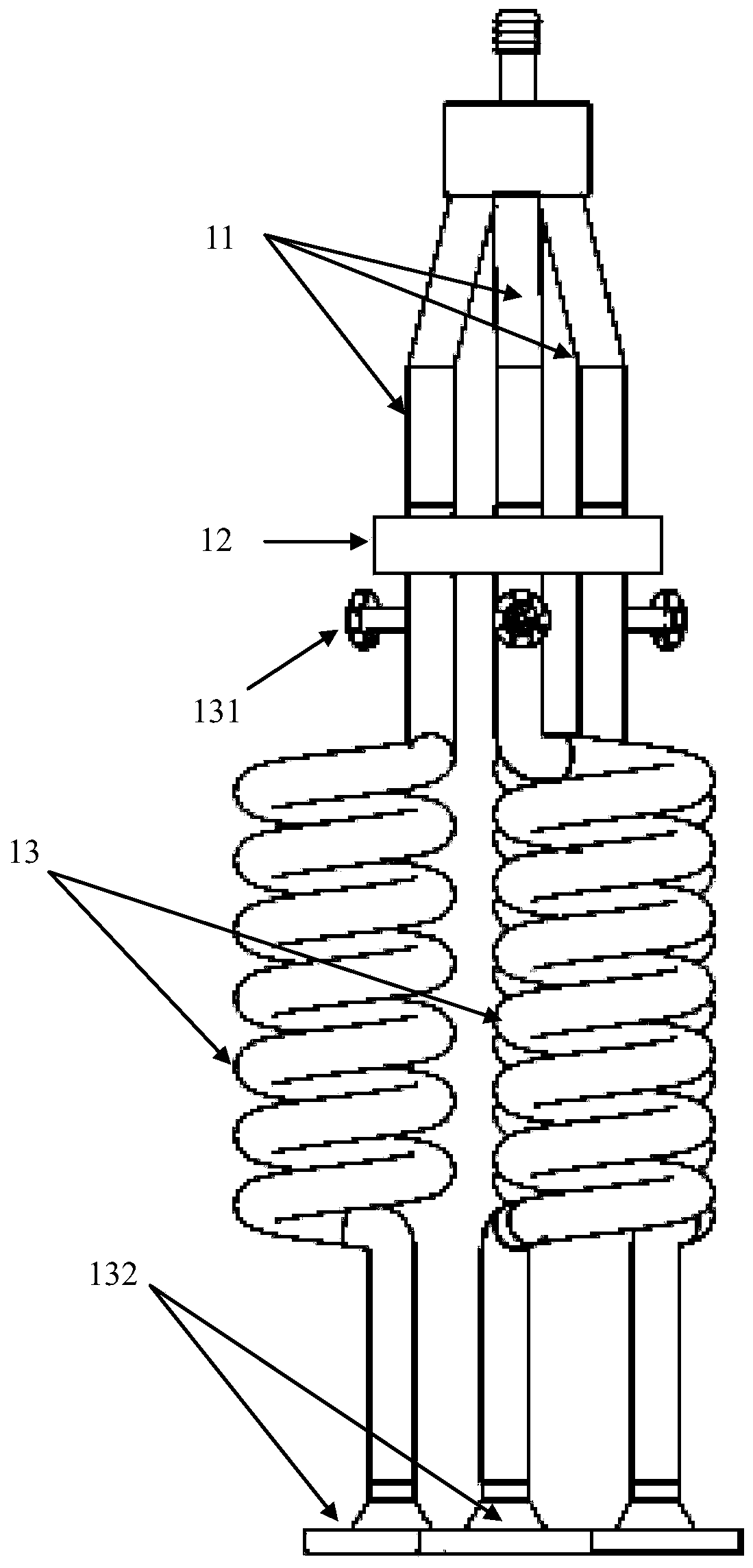

Embodiment 1

[0100] Pass the three refrigerant distribution pipes 11 through the limiting plate 12 and weld them to the pipe ends of the three unit refrigeration pipes 13. 3 through holes, with a card slot in the center, and an assembly flange 132 welded to the other end of the unit refrigeration pipe 13, forming the basic refrigeration unit 1;

[0101] One end of the header 21 welded with the assembly flange 132 is connected to the other end of the unit refrigeration pipe 13 through a flange, and the other end of the header 21 is connected to the opposite side of the opening of the header box 22, thereby realizing the basic refrigeration unit 1. For the connection with the refrigerant collecting device 2, the sealing cover plate 23 for bolt connection is used to seal the collecting box 22;

[0102]One end of the support keel 31 provided with internal threads is welded to the opposite face of the opening of the collecting box 22, and one end of the support keel 31 provided with external th...

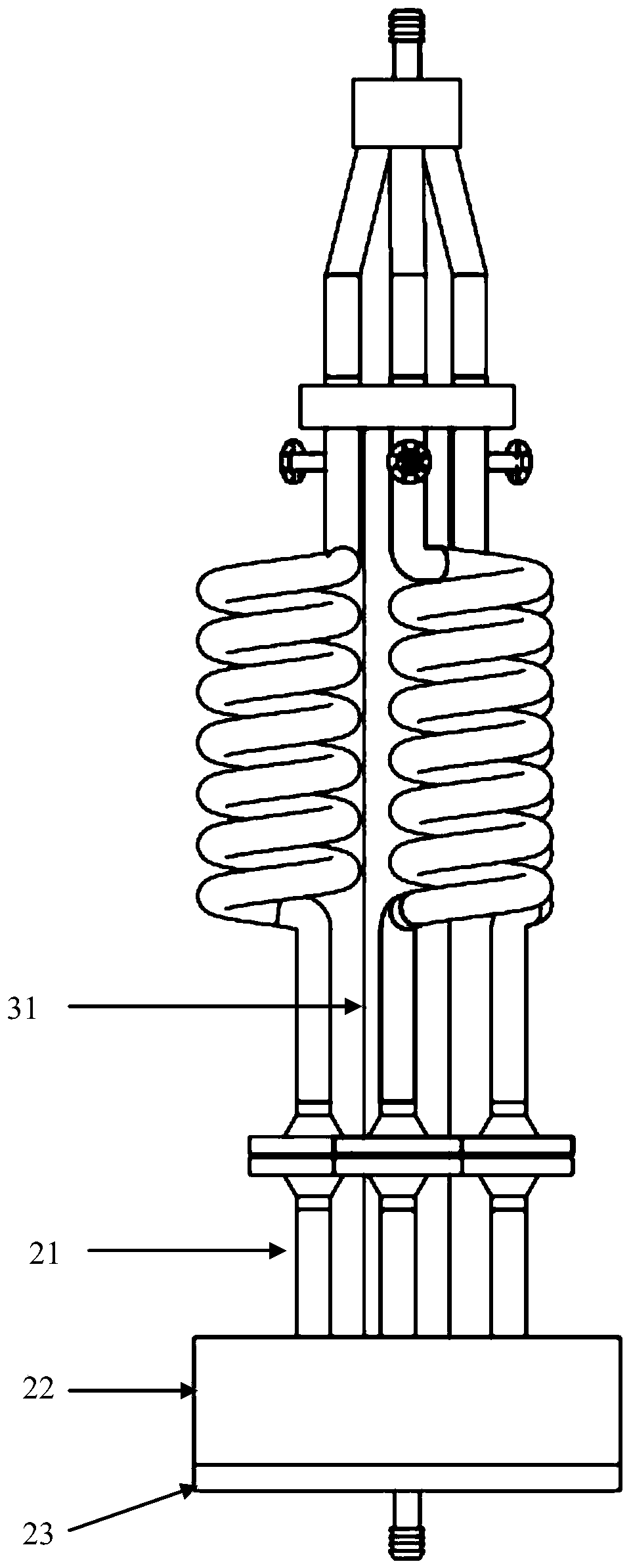

Embodiment 2

[0105] Pass the three refrigerant distribution pipes 11 through the limiting plate 12 and weld them to the pipe ends of the three unit refrigeration pipes 13. There are 3 through holes. The diameter of the through holes is slightly larger than the diameter of the refrigerant distribution pipe 11. There is a slot in the center of the limit plate 12. The other end of the unit refrigeration pipe 13 is welded with an assembly flange to form a basic refrigeration system. Unit 1;

[0106] On the basis of the basic refrigeration unit 1, add a continuous refrigeration unit, one end of the continuous refrigeration unit is connected to the basic refrigeration unit 1 through a flange, and the other end of the continuous refrigeration unit is connected to the refrigerant collecting device 2 through a flange . The added continuous refrigeration units are three unit refrigeration pipes 13 with assembly flanges 132 welded at both ends, and the three unit refrigeration pipes 13 are integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com