Preparation method of fermented tomato

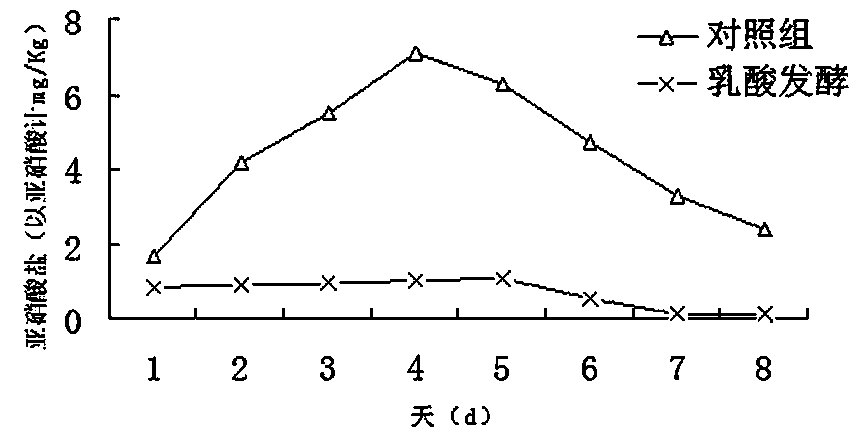

A tomato and fermented material technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve the effects of increasing appetite, low nitrite content, and short fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the preparation method of fermented tomato, carry out as follows: the first step, after fresh green tomato, salt and water are mixed in the ratio of 100:4 to 6:60 to 70 by mass ratio, obtain unfermented material The second step is to inoculate the strains into the unfermented material, and obtain the fermented material after fermentation at 35°C for 48 hours, wherein the inoculum amount of the strains is 5%, and the strains are composed of Lactobacillus plantarum and Lactobacillus pentosus , the mass ratio of Lactobacillus plantarum and Lactobacillus pentosus is 2:1; the third step, add the required amount of white sugar, white vinegar, fennel seeds, black pepper, garlic, bay leaves and mustard seeds to the fermentation material and mix well , and then get fermented tomato after high temperature sterilization.

[0018] The preparation method described in this example uses green tomatoes as fermentation raw materials, and Lactobacillus plantarum and Lactoba...

Embodiment 2

[0023] Embodiment 2: the preparation method of fermented tomato, carry out as follows: the first step, after fresh green tomato, salt and water are mixed in the ratio of 100:4 or 6:60 or 70 by mass ratio, obtain unfermented material The second step is to inoculate the strains into the unfermented material, and obtain the fermented material after fermentation at 35°C for 48 hours, wherein the inoculum amount of the strains is 5%, and the strains are composed of Lactobacillus plantarum and Lactobacillus pentosus , the mass ratio of Lactobacillus plantarum and Lactobacillus pentosus is 2:1; the third step, add the required amount of white sugar, white vinegar, fennel seeds, black pepper, garlic, bay leaves and mustard seeds to the fermentation material and mix well , and then get fermented tomato after high temperature sterilization.

Embodiment 3

[0024] Embodiment 3: the preparation method of fermented tomato, carry out as follows: the first step, after fresh green tomato, salt and water are mixed in the ratio of 100:4:70 by mass ratio, obtain unfermented material; Second step , inoculate the strains into the unfermented material, and ferment at 35°C for 48 hours to obtain the fermented material, wherein the inoculum amount of the strains is 5%, the strains are composed of Lactobacillus plantarum and Lactobacillus pentosus, and Lactobacillus plantarum The mass ratio to Lactobacillus pentosus is 2:1; in the third step, add the required amount of white sugar, white vinegar, fennel seeds, black pepper, garlic, bay leaves and mustard seeds to the fermentation material and mix evenly, and then pass through high temperature Fermented tomatoes are obtained after sterilization.

[0025] The fermented tomato obtained in Example 3 had a nitrite content of 1.07 mg / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com