Rolling roller, rolling crushing part and kitchen waste disintegrating and slurrying device

A technology of food waste and processing equipment, which is applied in the field of centrifuges, can solve the problems that the drum pulper cannot directly use the waste for processing, and achieve the effects of improving waste processing capacity, saving resources, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Hereinafter, the present invention will be further described with reference to the drawings and specific embodiments.

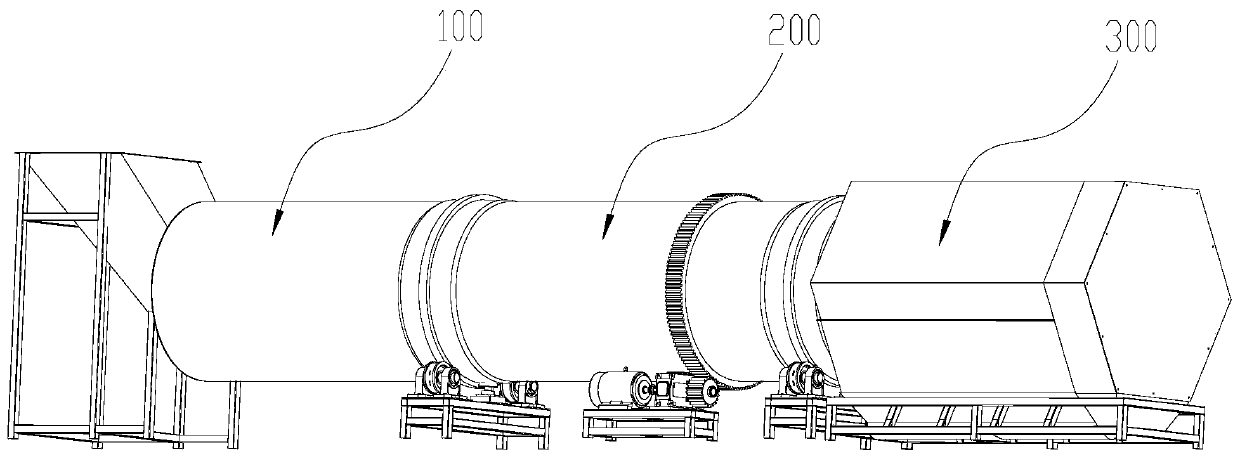

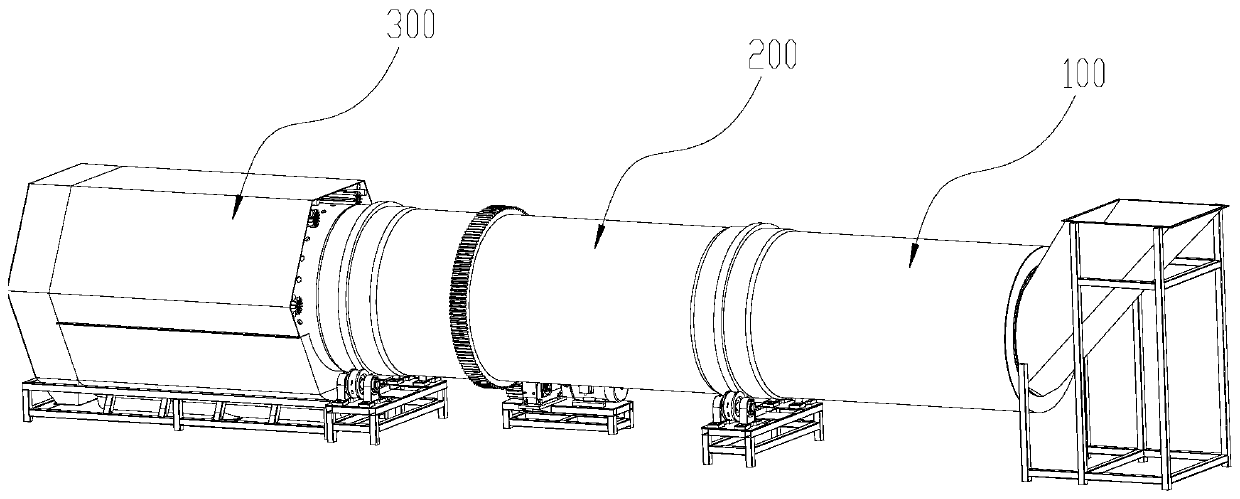

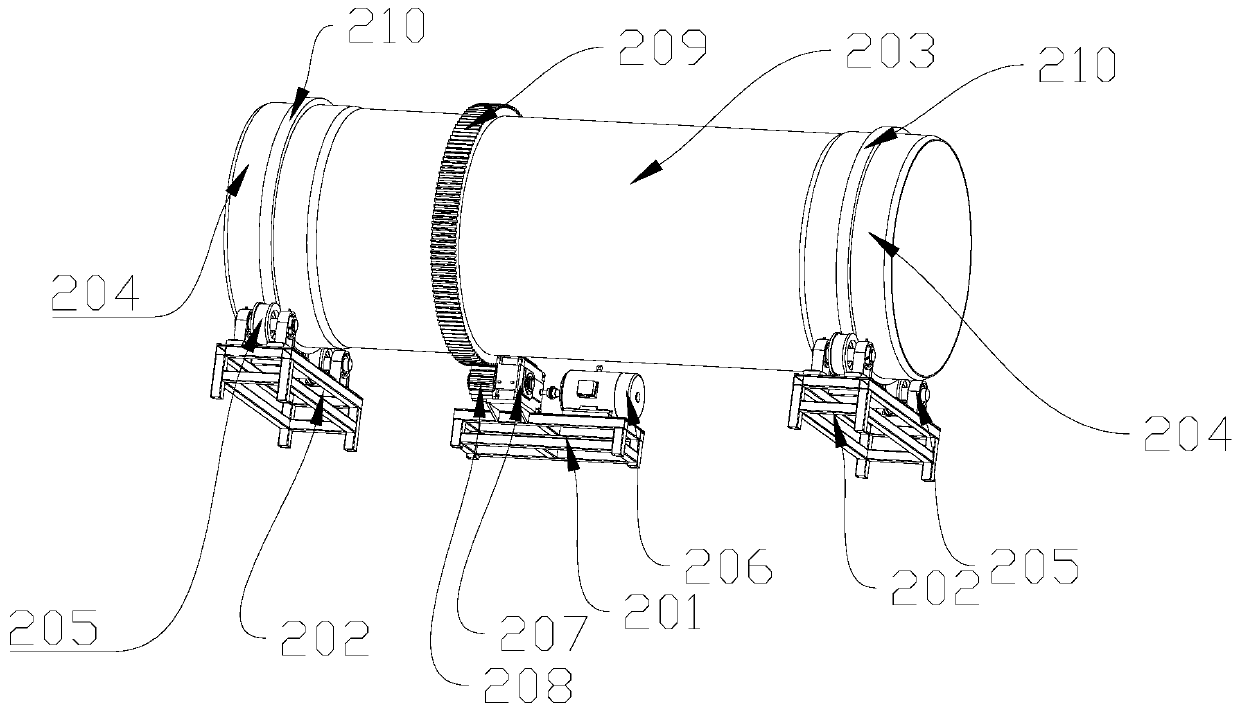

[0081] According to the design idea of the present invention, the technical core equipment of food waste treatment is a roller-type rolling drum pulping, screening and slag removal integrated machine, also known as food waste crushing and desizing treatment equipment, see the structure Figure 1-2 , which includes: a roller body 220, a built-in rolling roller 250, a material inlet 105, and a light and heavy slag outlet, which are divided into three processing areas:

[0082] Homogeneous material throwing conveying area, which includes: shredding protruding teeth, inner wall anti-twisting rope, pushing material single wire spiral, inner wall throwing plate;

[0083] Built-in rolling area, which includes: helical teeth on the inner wall, outer helical teeth of the rolling roller 250, a positioning body in the middle of the rolling roller 250, a positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com