Intelligent type motor machine seat hole machining special machine and use method thereof

A motor frame and hole processing technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of polluting the environment, time-consuming and laborious disassembly of the motor frame, and labor, so as to avoid dust generation and improve Accuracy and the effect of rational utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

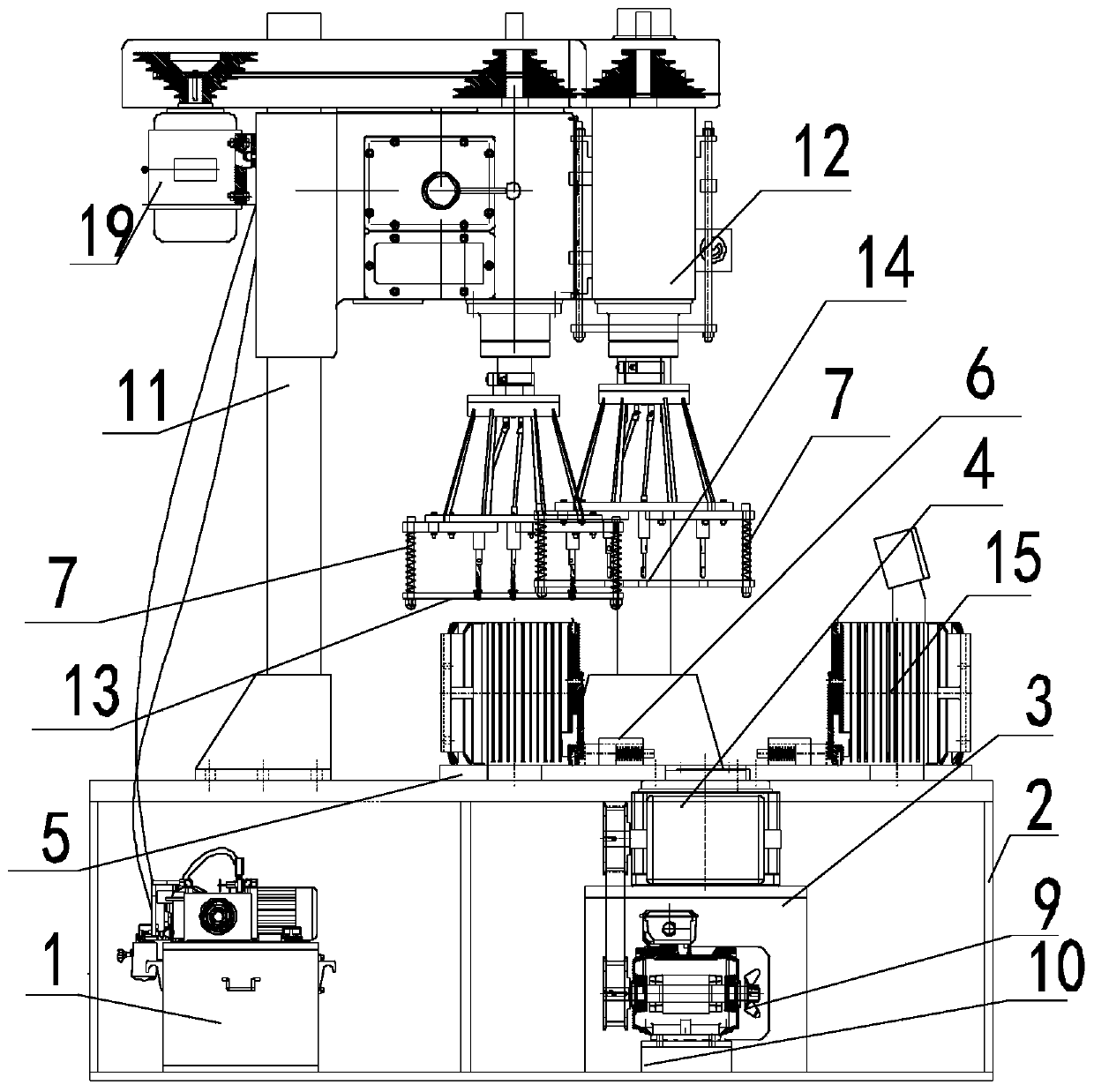

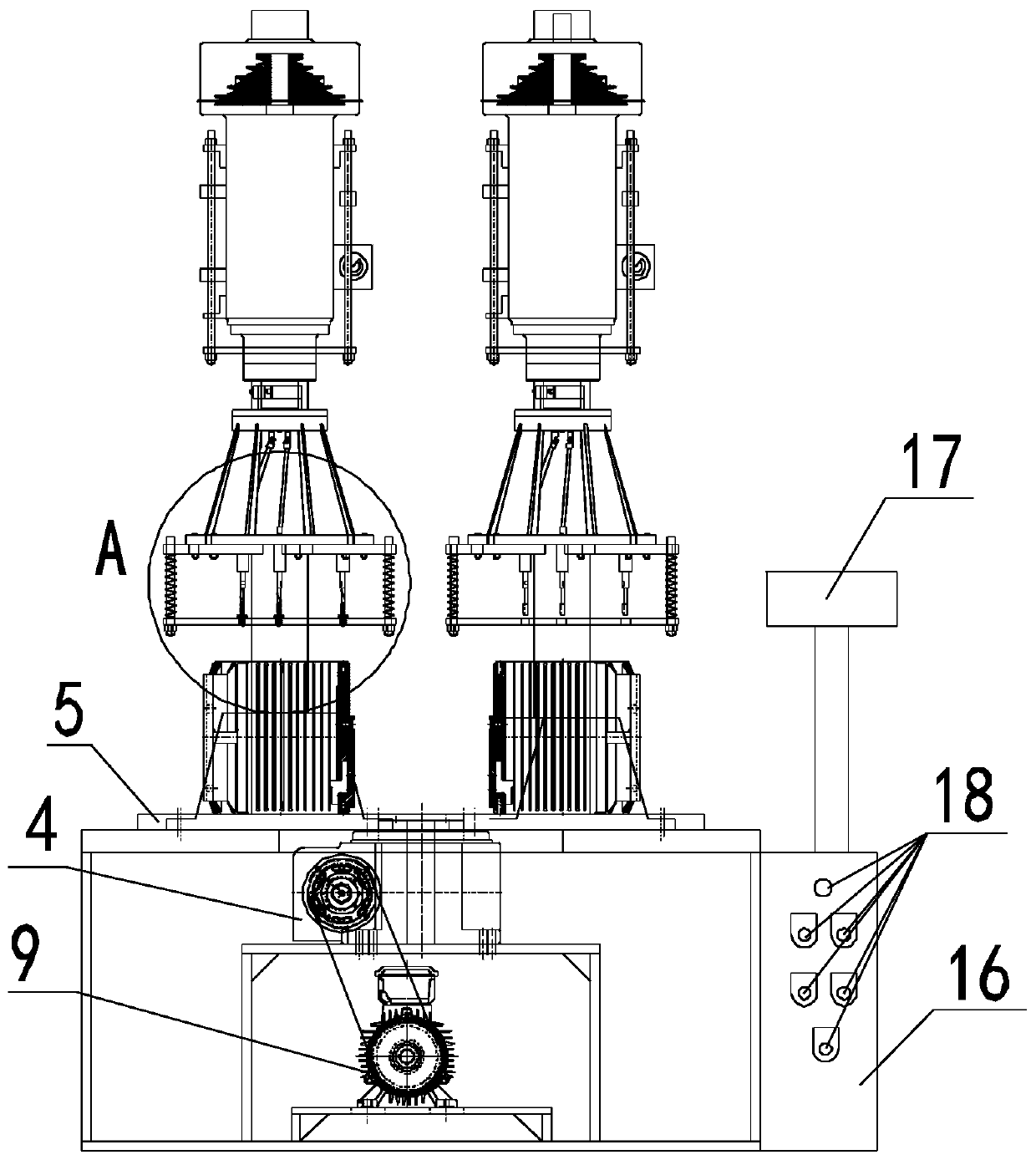

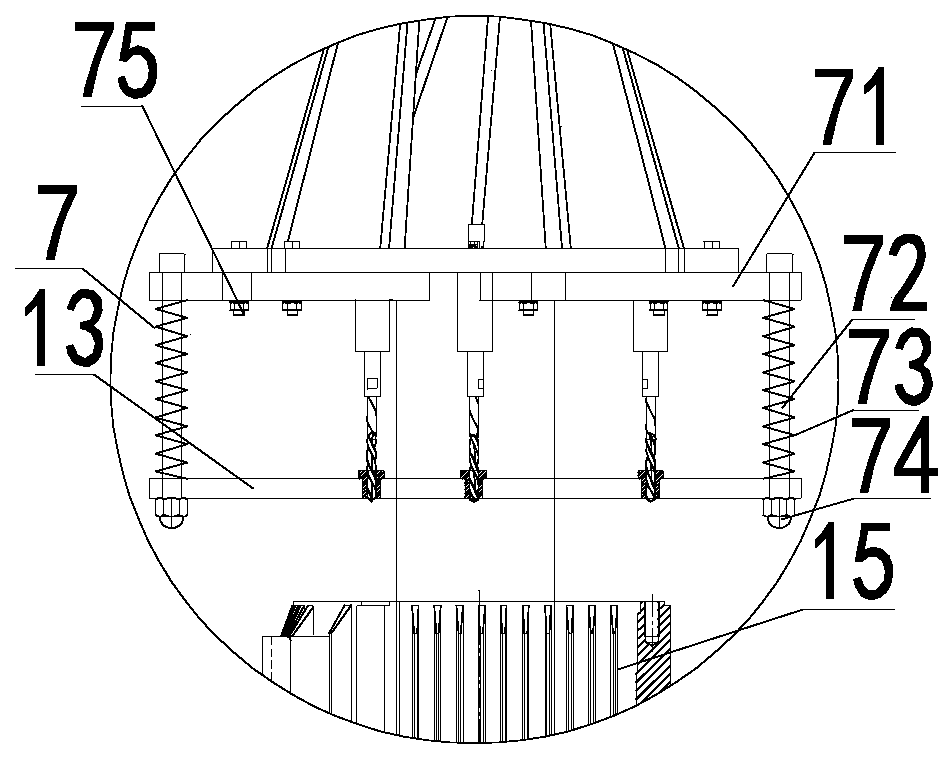

[0017] Embodiment 1: with reference to attached Figure 1-Figure 6 . An intelligent motor frame hole processing special machine, including a special machine support 2 and a hydraulic station 1, the hydraulic station 1 is arranged at the lower part of the special machine support 2, and a divider 4 is installed in the special machine support 2 through a divider installation bracket 3, A divider turntable 5 is installed on the output shaft head of the divider 4, and the divider turntable 5 is located at the upper end of the panel of the special plane support 2 (that is, the upper end surface of the special plane support 2 panel has an output shaft through hole and the output shaft through hole runs through the special plane. The upper and lower end surfaces of the bracket 2 panel, the splitter is arranged directly below the output shaft through hole and the output shaft head of the splitter 4 passes through the output shaft through hole and extends out of the upper end surface of...

Embodiment 2

[0022] Embodiment 2: on the basis of embodiment 1, with reference to appended Figure 7-Figure 8 . Also includes a cutting fluid recycling device 8, the upper end of the cutting fluid water tank 81 in the cutting fluid recycling device 8 is provided with a cutting fluid circulation pump 82, and the water inlet of the cutting fluid circulation pump 82 is provided with an extension pipe and the extension pipe The lower port is located in the cutting fluid water tank 81, the lower end of the bottom plate of the drilling multi-axis device is provided with one or more first cutting fluid nozzles 83, and the lower end of the bottom plate of the tapping multi-axis device is provided with one or more first Two cutting fluid nozzles 84, the water inlet of the first cutting fluid nozzle 83 and the water inlet of the second cutting fluid nozzle 84 are respectively connected to the water outlet of the cutting fluid circulation pump 82 through the cutting fluid output pipe. The end face i...

Embodiment 3

[0024] Embodiment 3: on the basis of embodiment 1, with reference to appended Figure 1-Figure 8 . A method for using an intelligent motor base hole processing special machine, step 1, install the motor base 15 to be processed on the machine located at the loading and unloading station through the through hole of the motor base and the machine base positioning seat 61 body concave-convex fit On the seat positioning seat 61, turn the nut 66 afterwards to make the fork of the locator 62 slide block 64 fork the lug of the motor support 15, and realize the positioning installation of the motor support 15; Step 2, the PLC controller controls the rotation of the motor 9 and Drive the splitter 4, and the splitter 4 is brought to the splitter turntable 5 to rotate until the motor base 15 to be processed is delivered to the drilling station. At this time, the PLC controller controls the motor 9 to stop rotating and controls the multi-axis drilling machine 11 to work. The multi-axis dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com