Continuous die cutting and arranging equipment for polaroids and production technology thereof

A polarizer and die-cutting technology, used in metal processing, strip winding, thin material processing, etc., which can solve the problems of small size, high time consumption, and difficult operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

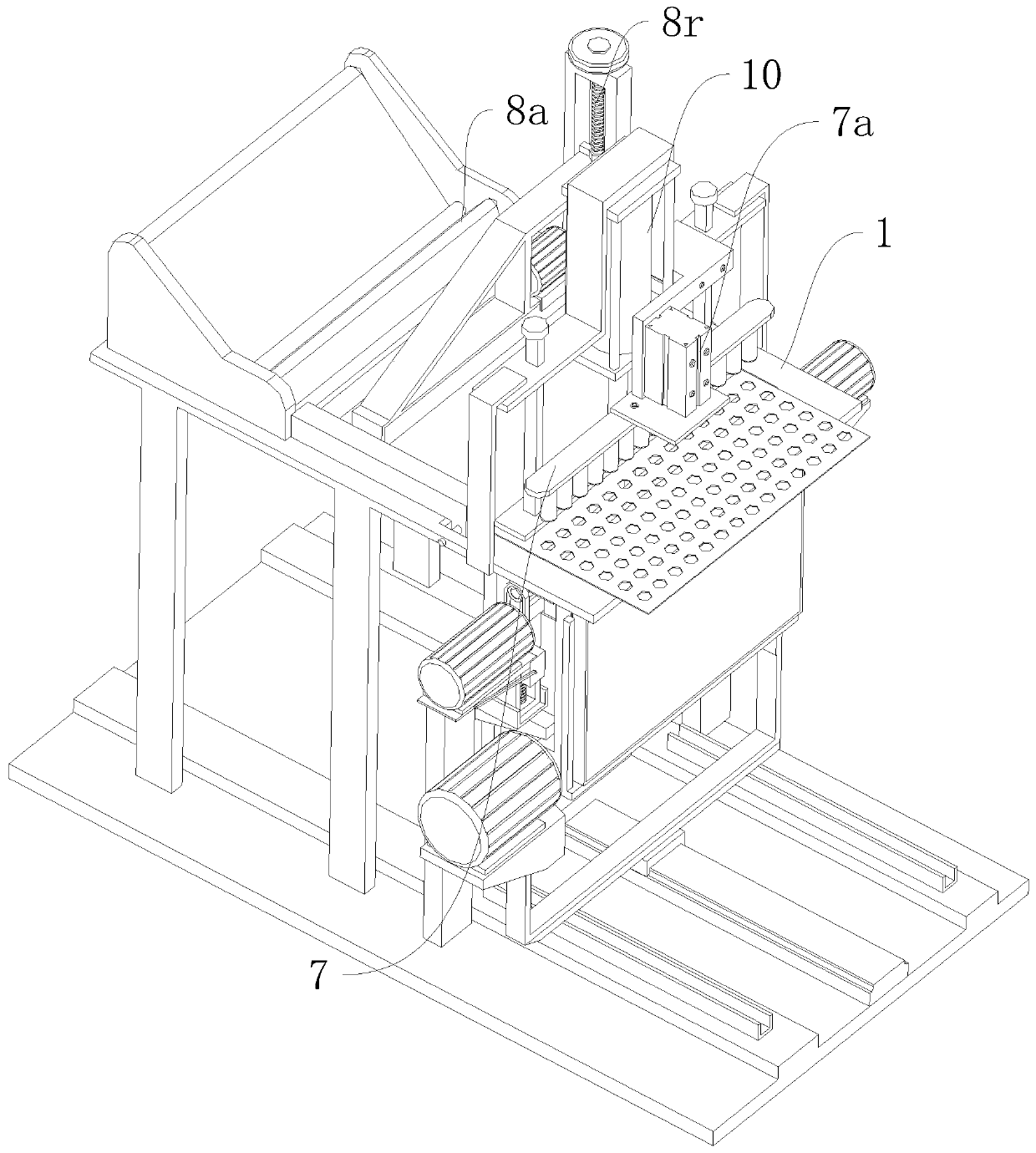

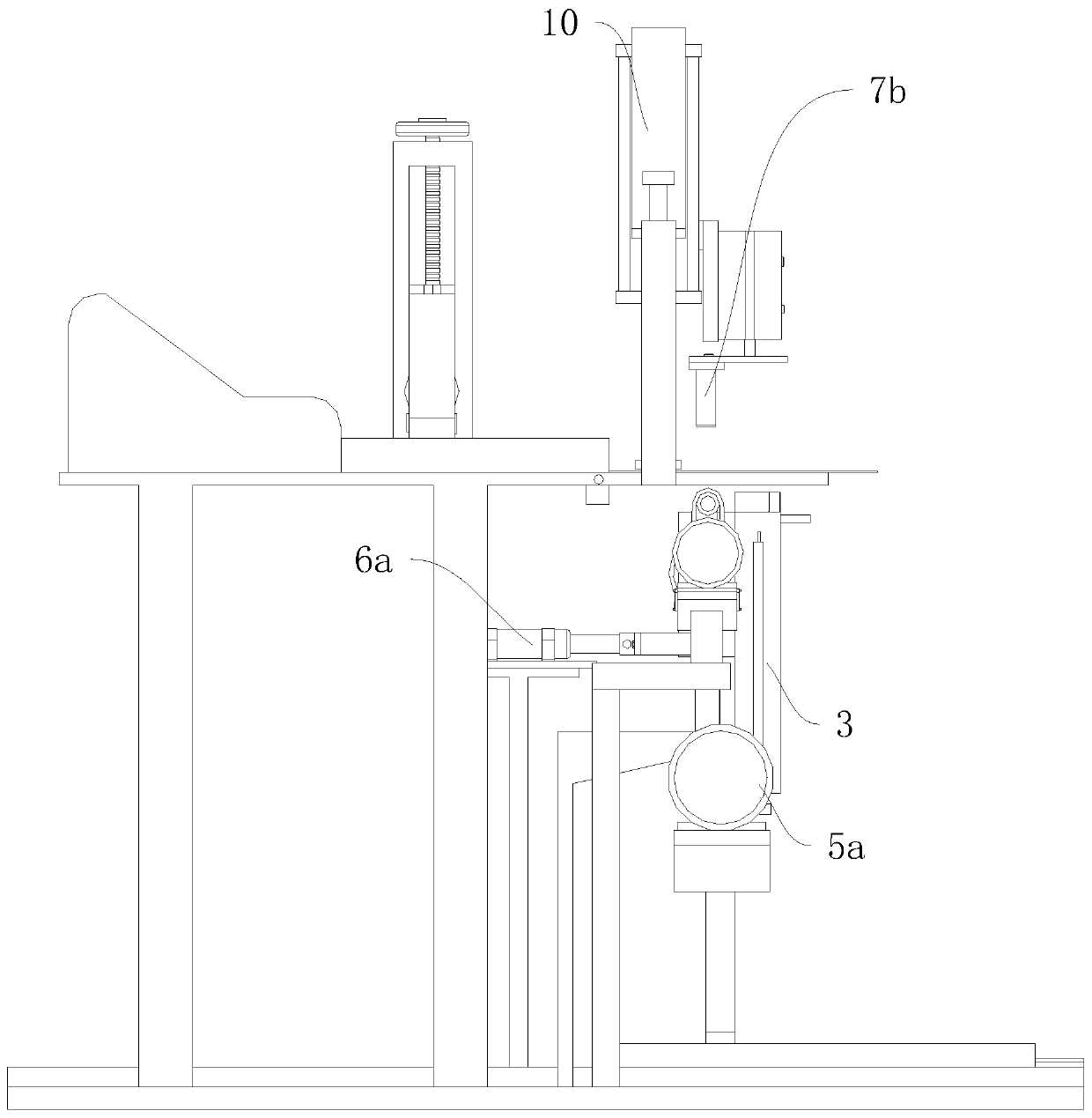

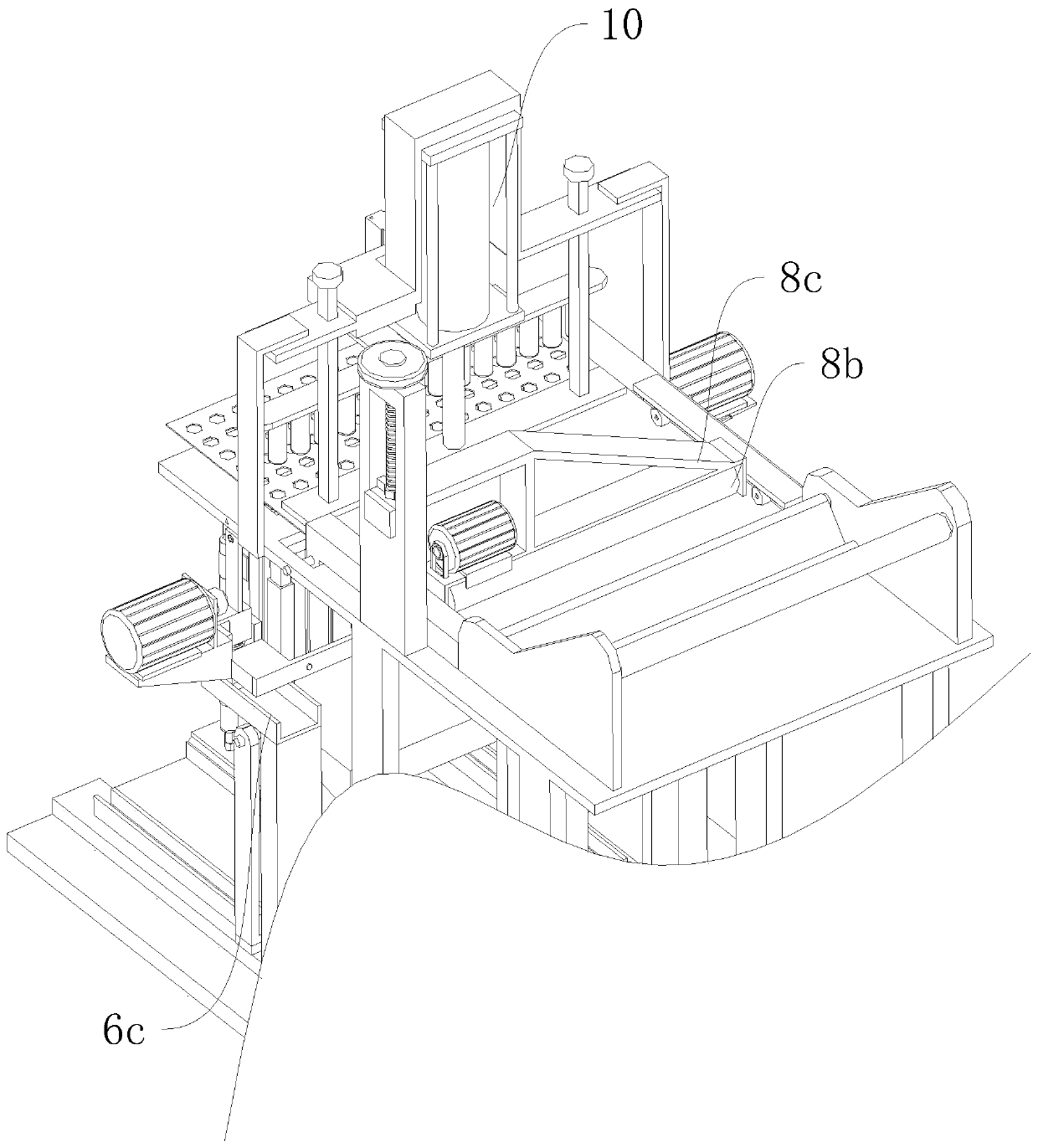

[0049] refer to Figure 1 to Figure 11 A continuous die-cutting and finishing equipment for polarizers is shown, including a controller, a processing table 1, an unwinding mechanism, a die-cutting mechanism 10, an unloading mechanism, and a regularizing mechanism sequentially arranged on the processing table 1 along a straight line , the distance between the unloading mechanism and the die-cutting mechanism 10 is between 2.5cm and 3.5cm, the downstream end of the processing table 1 is provided with a discharge slot 1a, and the regularizing mechanism includes a replacement slot installed directly below the discharge slot 1a. Plate 2, the storage component arranged on the side of the replacement plate 2, and the shifting component arranged above the replacement plate 2, and the lower part of the replacement plate 2 is provided with a lifting component for driving it to move vertically into the discharge slot 1a, A position sensor 1b electrically connected to the controller is in...

Embodiment 2

[0059] The production process of the continuous die-cutting and finishing equipment of the polarizer described in embodiment 1 comprises the following steps:

[0060] Step 1. Unwind the rolled polarizer step-by-step by the unwinding mechanism. During the process, two side limit platens 9 form the anti-wrinkle limit on both sides. Finally, the unwinding end is step-by-step. Delivered to directly below the die-cutting mechanism 10;

[0061] Step 2, the die-cutting mechanism 10 starts to work, and performs die-cutting on the polarizer directly below it. After the die-cutting is completed, the unwinding mechanism transports the die-cut part of the polarizer to the area of the discharge slot 1a step by step, and then At this time, this area is filled by the replacement plate 2, so as to support the transported polarizer;

[0062] Step 3. The unloading mechanism presses down the multiple independent polarizers that have been die-cut in step 2, so that they are completely separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com