Plug-in hybrid electric vehicle power system

A hybrid electric vehicle and power system technology, applied in the field of plug-in hybrid electric vehicle power system, can solve the problems of difficult engine, poor matching, low power system work efficiency, etc., and achieve the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

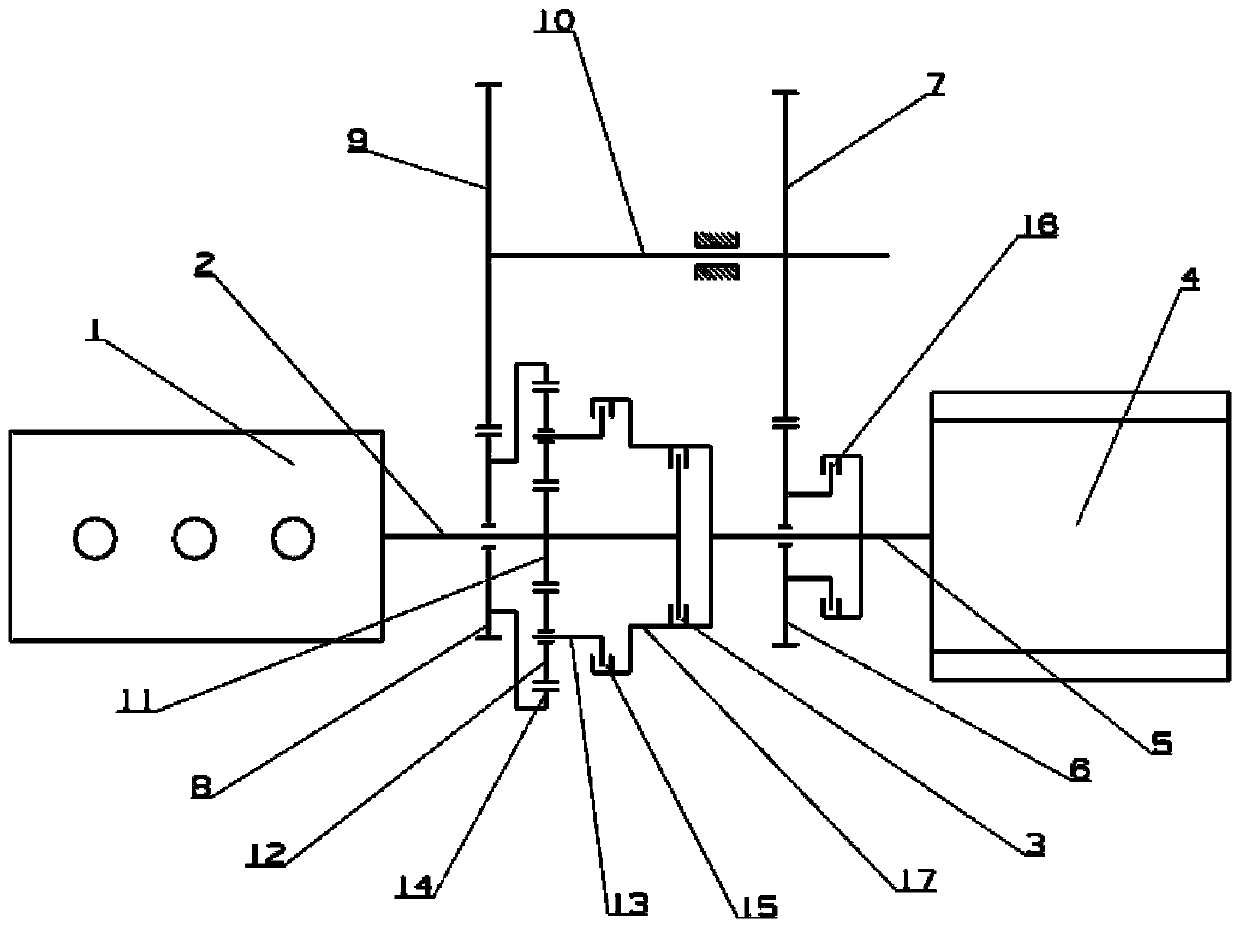

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] see figure 1 , the power system of the plug-in hybrid electric vehicle of the present invention includes: an engine 1 comprising a crankshaft 2, a first clutch 3, a drive motor 4 comprising a motor shaft 5, a second clutch 16, a first gear 6, and a second gear 7 :Depend on figure 1 It can be seen that the present invention also includes a third gear 8, a fourth gear 9, a connecting shaft 10, a third clutch 15 and a connecting shell 17, and includes a sun gear 11 located inside the planet carrier 13, which is rotatably installed on the planet carrier 13 The planetary gear 12 on the top, the planetary row of the ring gear 14 outside the planetary carrier 13; the engine 1, the third gear 8, the planetary row, the third clutch 15, the first clutch 3, the first gear 6, the second The clutch 16 and the drive motor 4 are arranged sequential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com