Self-optimization control device and method based on crushing working conditions

A technology of a control device and a control method, which is applied to earth movers/excavators, construction, etc., can solve problems such as unreasonable power setting of breakers, energy loss, and inability to achieve precise matching, and achieve precise and efficient power matching, Improve the effect of energy saving, improve the effect of operation monitoring and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

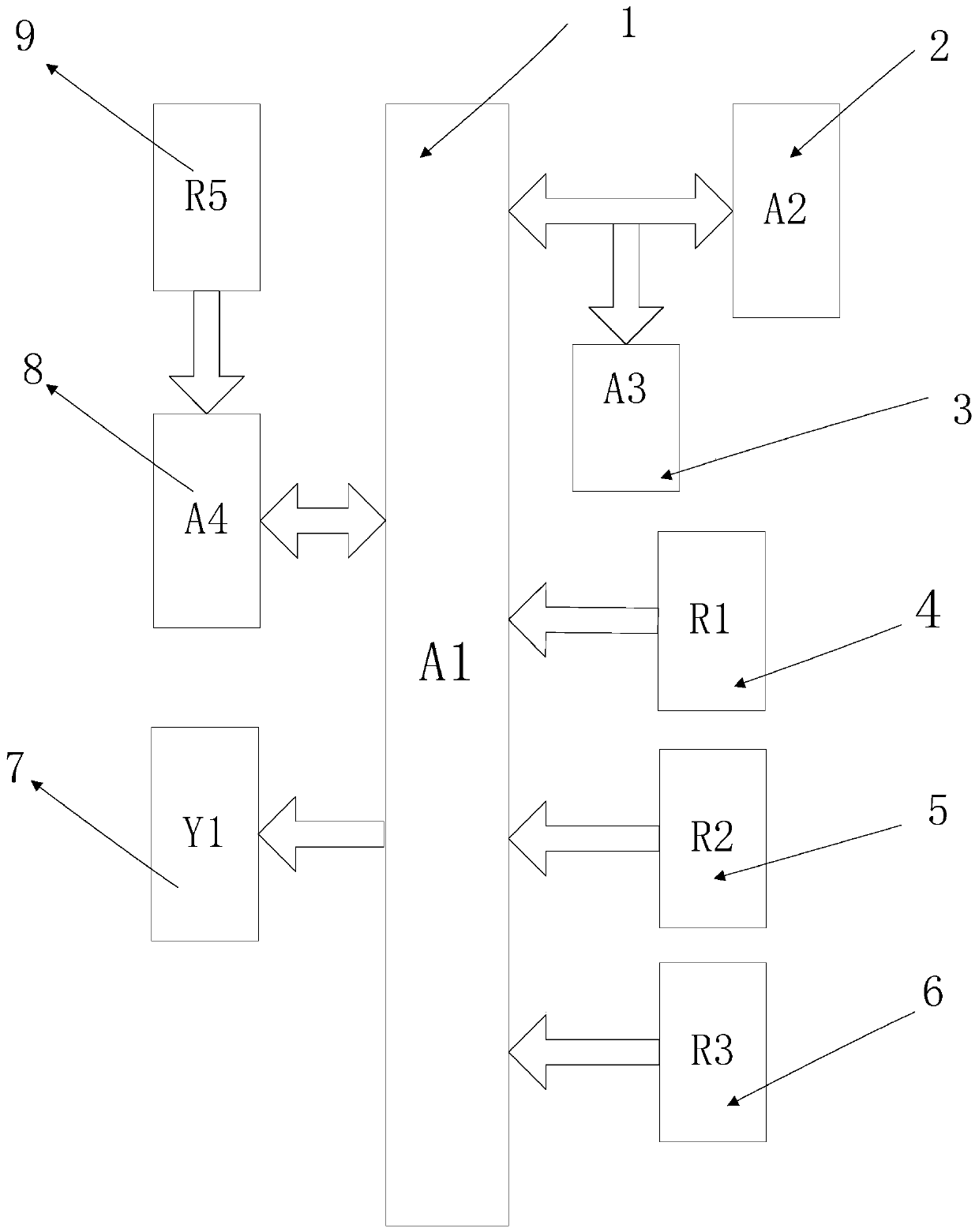

[0056] An embodiment of the present invention provides a self-optimizing control device based on crushing conditions, including:

[0057] A main controller, the main controller is used to control the power output of the breaker, and during specific implementation, an existing controller chip can be directly purchased from the market as the main controller of the embodiment of the present invention;

[0058] The electronic monitor 2 and the engine controller 8; the electronic monitor 2 and the engine controller 8 are all connected to the main controller through the bus; preferably, the electronic monitor 2 and the engine controller 8 are all connected through the CAN bus It is connected with the main controller; the electronic monitor 2 is used for setting parameters of the self-optimizing control device and selecting an optimal control mode. In the actual application process, the electronic monitor 2 can be a touch display, Other devices that can realize display and control ca...

Embodiment 2

[0072] Based on embodiment 1, the difference between this embodiment and embodiment 1 is:

[0073] The self-optimizing control device based on crushing working conditions also includes: a crushing pilot pressure sensor 5 located on the crushing pilot oil circuit of the breaker, used to detect the pressure in the crushing pilot oil circuit, and its output terminal is connected to the main control circuit. The input terminal of the device is connected;

[0074] The main pump pressure sensor 4, the crushing pilot pressure sensor 5 and the nitrogen pressure sensor 6 are all voltage-type sensors, which output a voltage signal of 0.5-4.5V;

[0075] Alternatively, the main pump pressure sensor 4, the crushing pilot pressure sensor 5 and the nitrogen pressure sensor 6 are all current sensors, which output a current signal of 4-20mA.

[0076] In summary, the working principle of the self-optimizing control device based on crushing working conditions in this embodiment is as follows: ...

Embodiment 3

[0086] The difference between this embodiment and embodiment 1 is:

[0087] The self-optimizing control device based on crushing working conditions also includes a nitrogen pressure sensor 6, which is used to be installed on the breaker to detect the pressure of nitrogen in the nitrogen chamber of the breaker, and its output terminal is connected to the connected to the input of the main controller.

[0088] In summary, the working principle of the self-optimizing control device based on crushing working conditions in this embodiment is as follows:

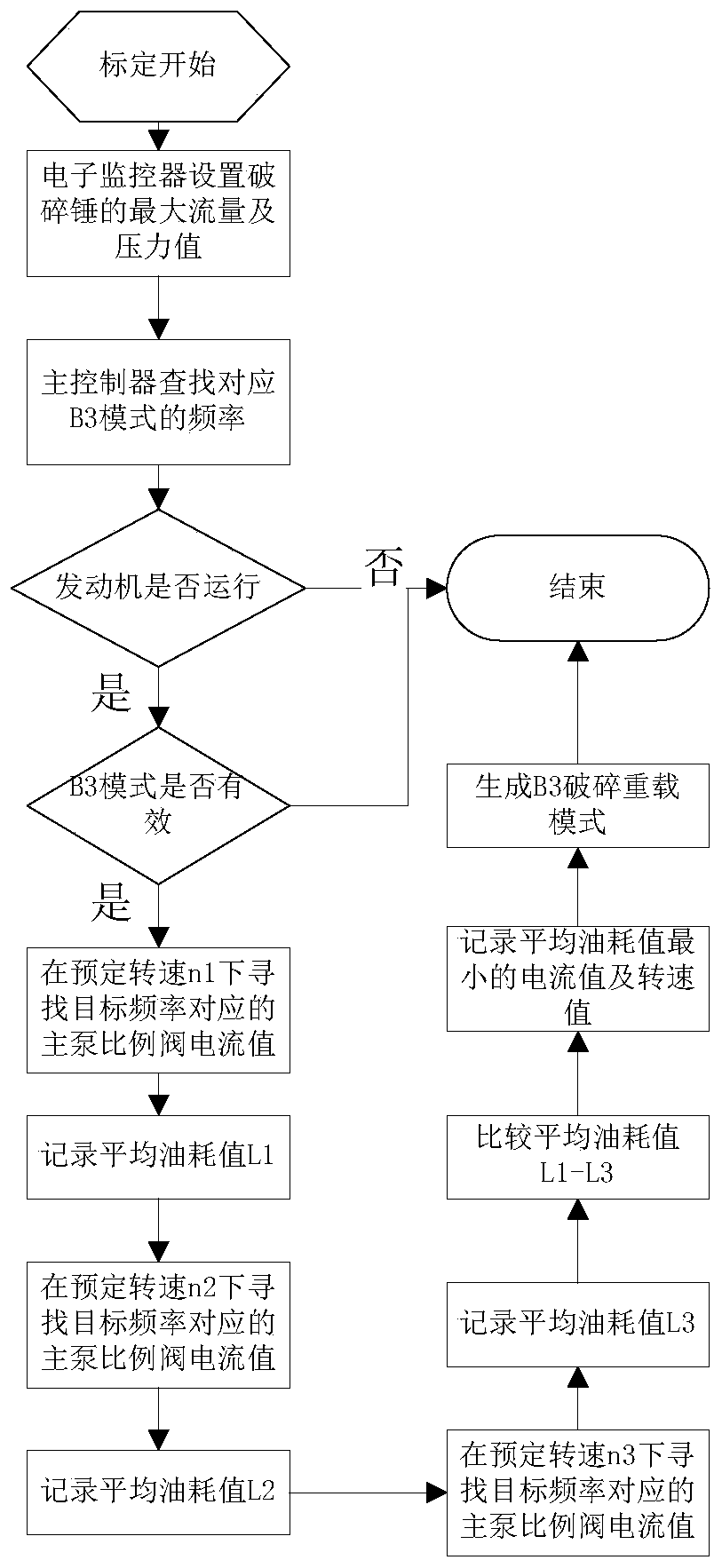

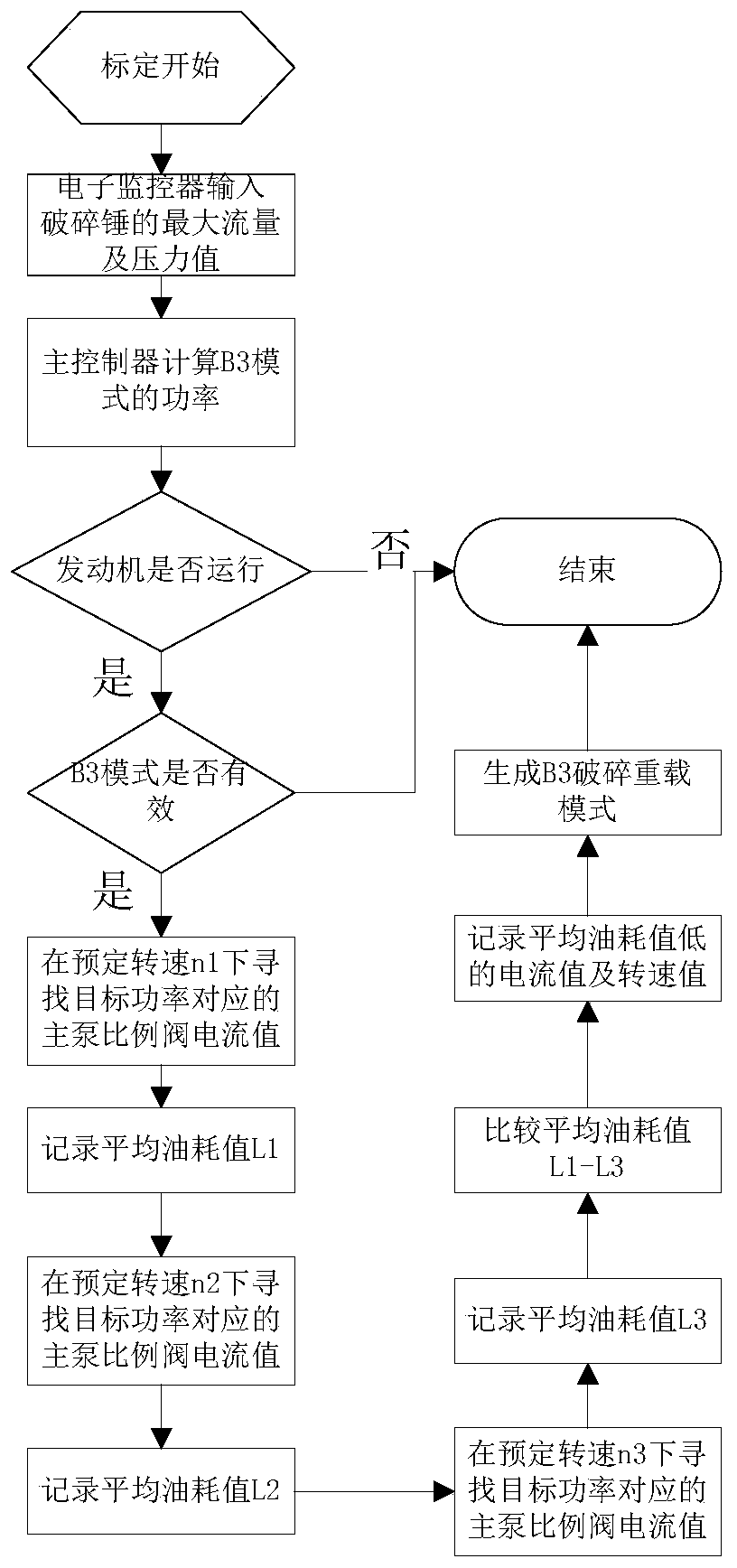

[0089] (1) At least one optimal control mode is preset in the main controller, and at least one crushing power mode is respectively set in each optimal control mode, and each crushing power mode is provided with a corresponding target value;

[0090] (2) Use the electronic monitor 2 to set the maximum flow rate and pressure value of the breaker;

[0091] (3) Use the electronic monitor 2 to select a certain optimization control m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com