Integral assembly type frame structure house

A frame structure and prefabricated technology, which is applied in the direction of building structure and construction, can solve problems such as difficult anti-corrosion and fire prevention technology, complex node connection structure, structural integrity problems, etc., to ensure stability, simple adjustment, and improve stability The effect of sex and intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

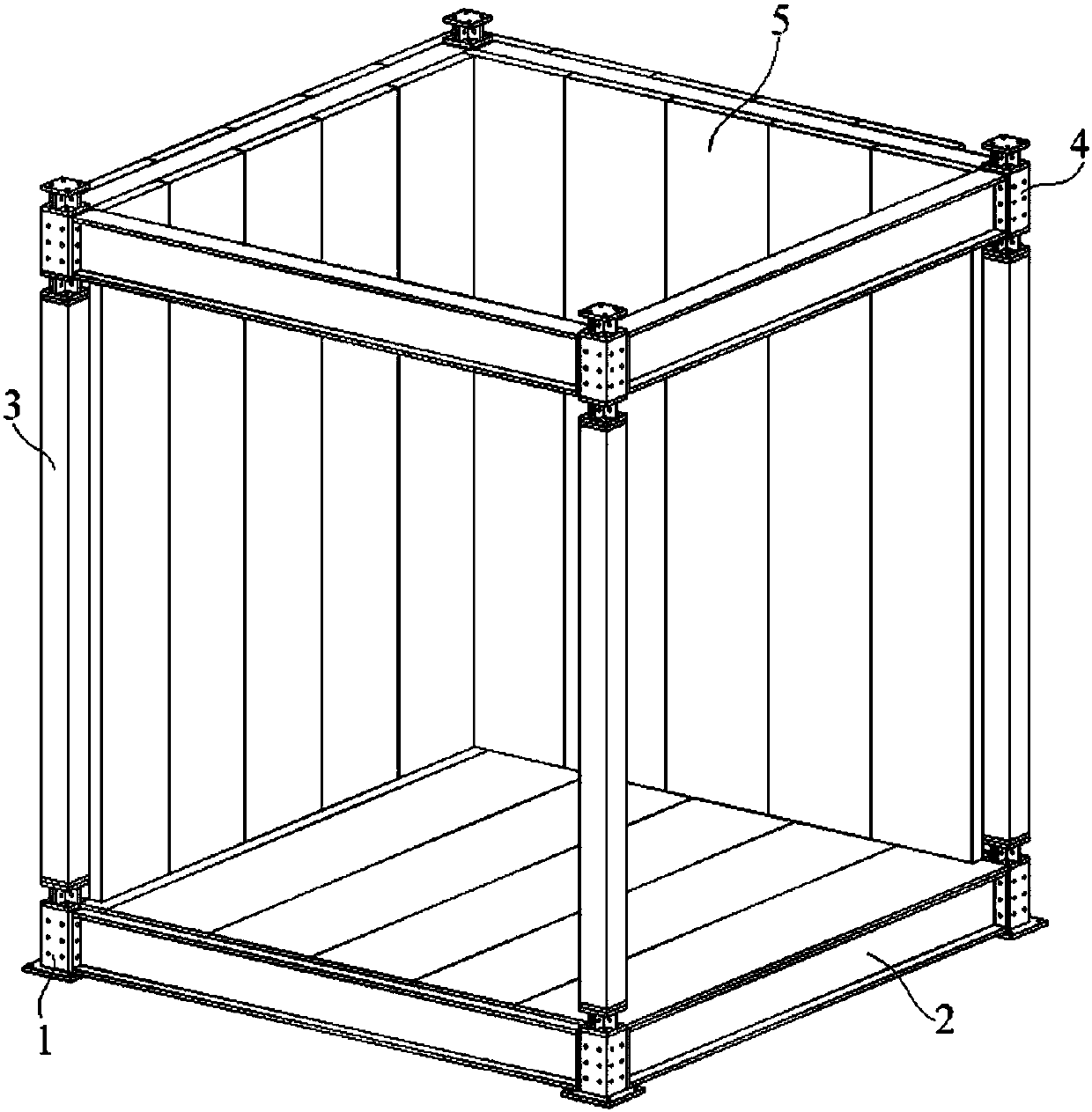

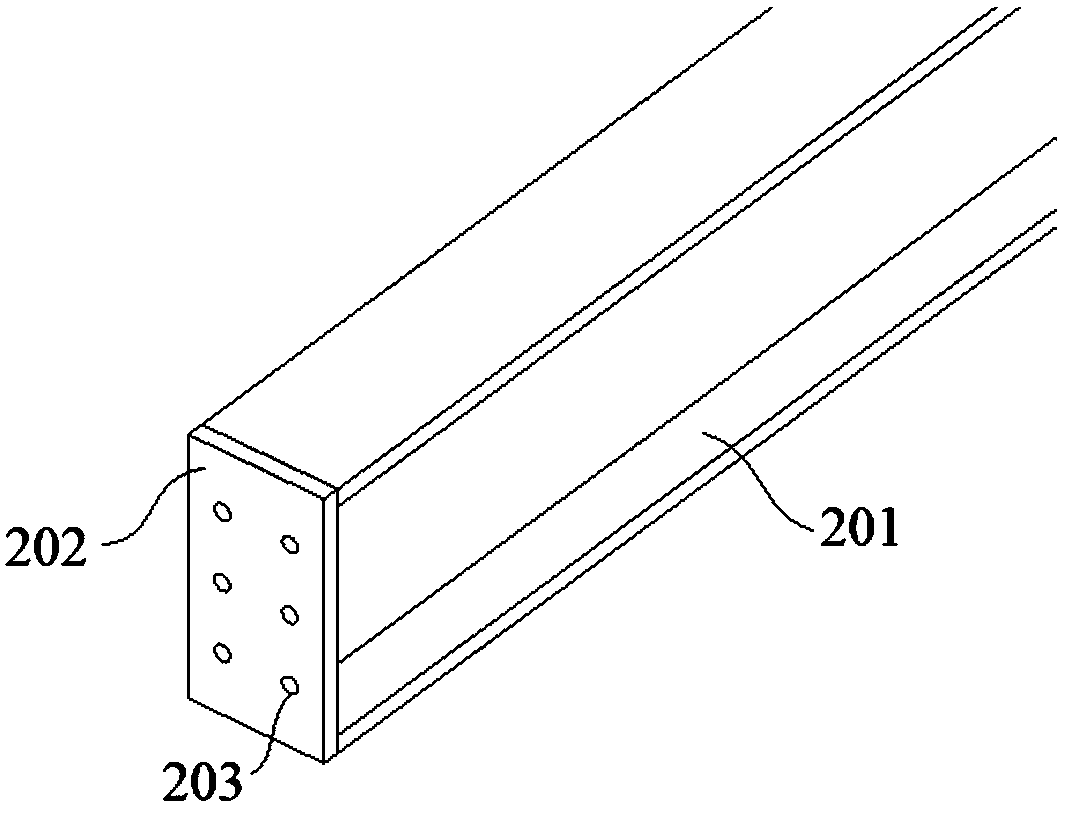

[0025] Embodiment 1: An integrally assembled frame structure house, including a base 1, a beam 2, a column 3, a central node 4 and a wall panel 5, the base 1 is connected to the column 3 in the vertical direction, and connected to the beam 2 in the horizontal direction connected, the central node 4 is connected to two adjacent columns 3 in the vertical direction, and connected to the crossbeam 2 in the horizontal direction, and the wallboard 5 is fixedly connected to the crossbeam 2;

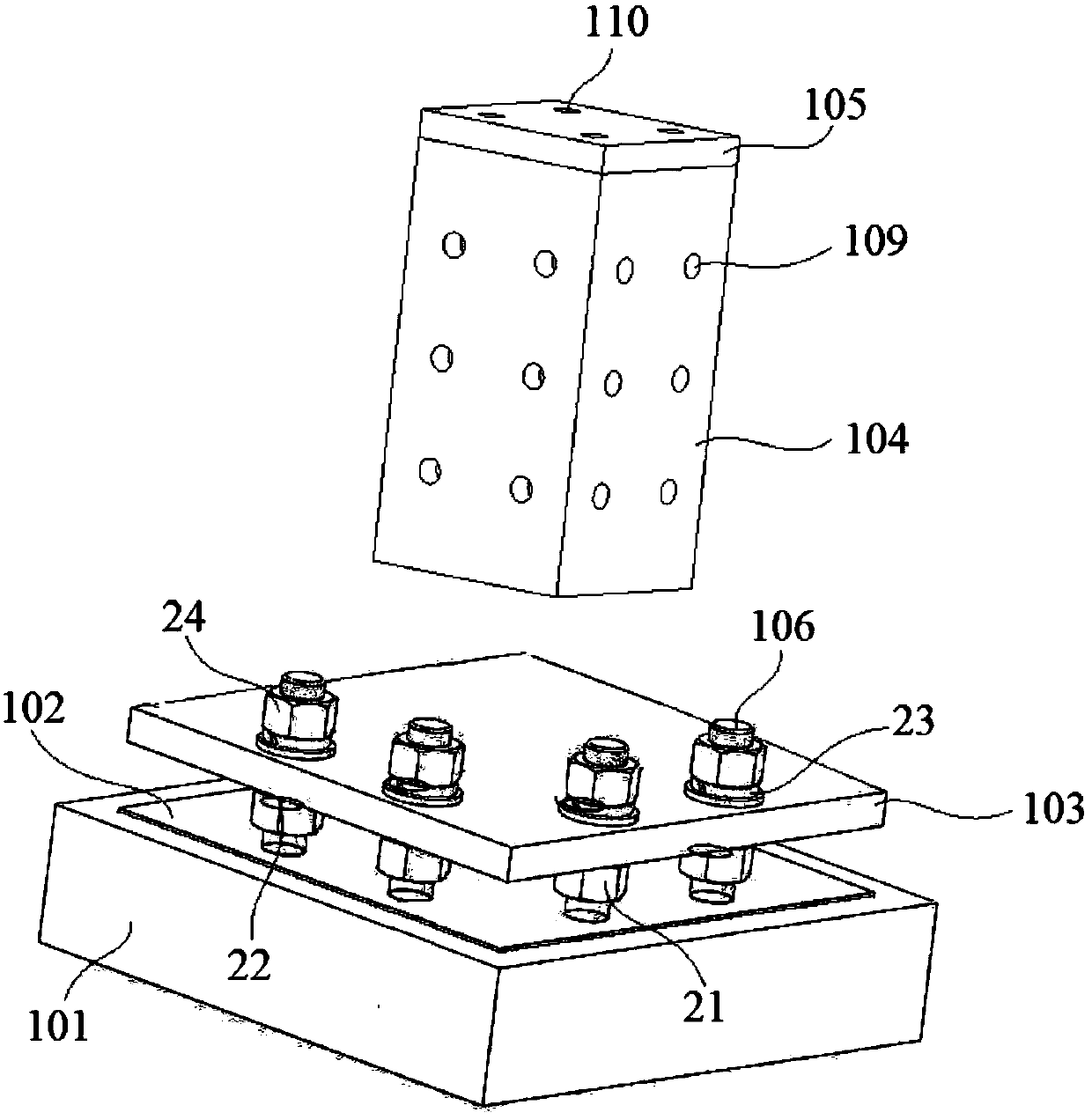

[0026] The base 1 further includes a foundation 101, a base plate 102, a base plate 103, a square tube 104 and a cover plate 105, the base plate 102 is arranged on the base 101 and the upper surface, and the base plate 103 is connected to the base 101 and the base plate 102 through several studs 106. Fixed connection, the lower surface of the square tube 104 is fixedly connected to the upper surface of the base plate 103, the cover plate 105 is fixedly connected to the upper surface of the square...

Embodiment 2

[0030] Embodiment 2: An integrally assembled frame structure house, including a base 1, a beam 2, a column 3, a central node 4 and a wall panel 5, the base 1 is connected to the column 3 in the vertical direction, and connected to the beam 2 in the horizontal direction connected, the central node 4 is connected to two adjacent columns 3 in the vertical direction, and connected to the crossbeam 2 in the horizontal direction, and the wallboard 5 is fixedly connected to the crossbeam 2;

[0031]The base 1 further includes a foundation 101, a base plate 102, a base plate 103, a square tube 104 and a cover plate 105, the base plate 102 is arranged on the base 101 and the upper surface, and the base plate 103 is connected to the base 101 and the base plate 102 through several studs 106. Fixed connection, the lower surface of the square tube 104 is fixedly connected to the upper surface of the base plate 103, the cover plate 105 is fixedly connected to the upper surface of the square ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com