Floating nuclear power plant water feeding pump necessary net positive suction head setting method

A technology of NPSH and feedwater pumps, which is applied in the direction of pump components, variable capacity pump components, machines/engines, etc., can solve the problem of reducing the effective NPSH of feedwater pumps, small cycle values, and excessive swing angle values major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

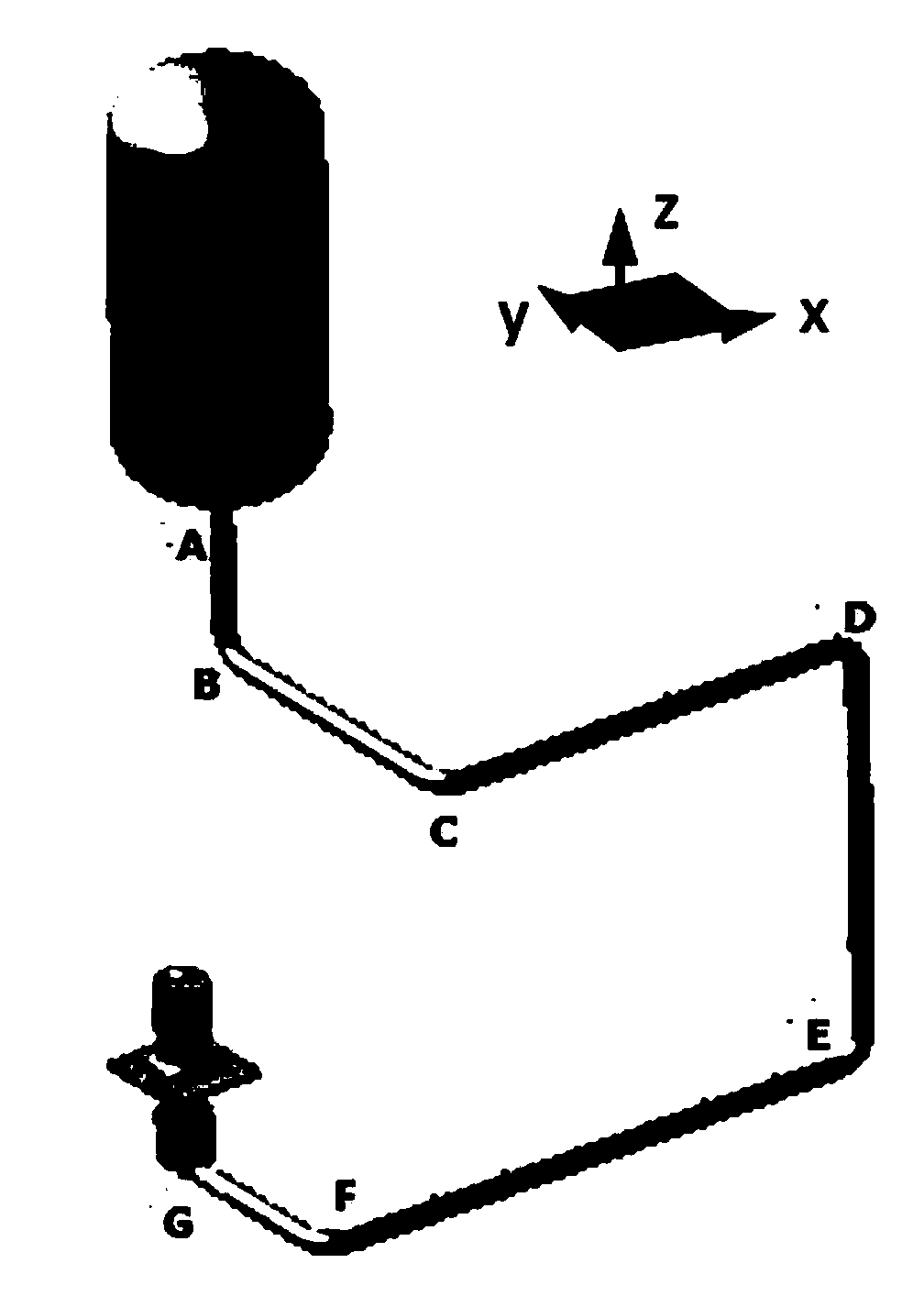

[0062] see figure 1 As shown, the embodiment of the present invention provides a method for setting the necessary NPSH of the feedwater pump of a floating nuclear power plant. The method is simple and easy to use, and can calculate the necessary NPSH to meet the operation requirements of the nuclear power plant feedwater pump under ocean conditions.

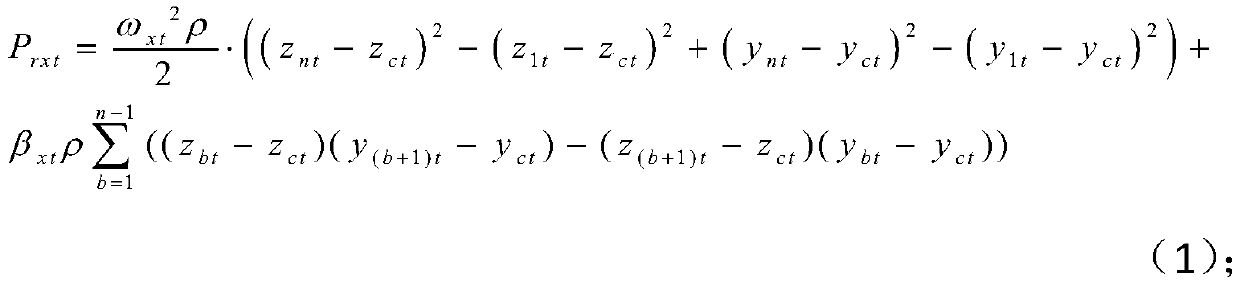

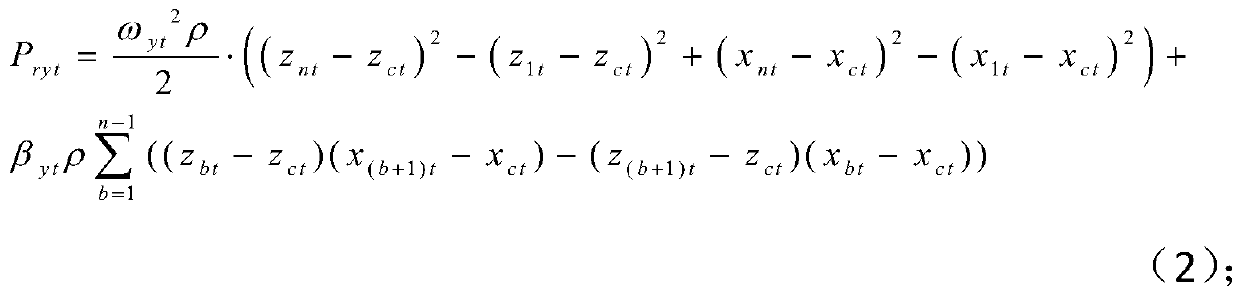

[0063] This method can calculate the additional pressure drop suffered by the translation and rotation of the pipeline in three directions, and can judge the magnitude of the force on the pipeline in the three directions numerically, so that by adjusting the nodes in the three directions Adjust the effective NPSH based on the distance from the center of the ship to the swing center of the hull. If the force in the X direction is large, the distance from the node to the center of the hull swing in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com