Preparation method of miniature temperature-controllable automatic heating dehumidifying plugging plate

An automatic heating and miniature technology, which is applied in the direction of measuring devices, suspension and porous material analysis, particle suspension analysis, etc., can solve the problems of insufficient dehumidification detection, high power consumption, complex device structure, etc., to achieve sufficient and uniform heating, Improved accuracy, convenient and easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the accompanying drawings.

[0022] A miniature temperature-controllable automatic heating and dehumidification insert, comprising the following steps:

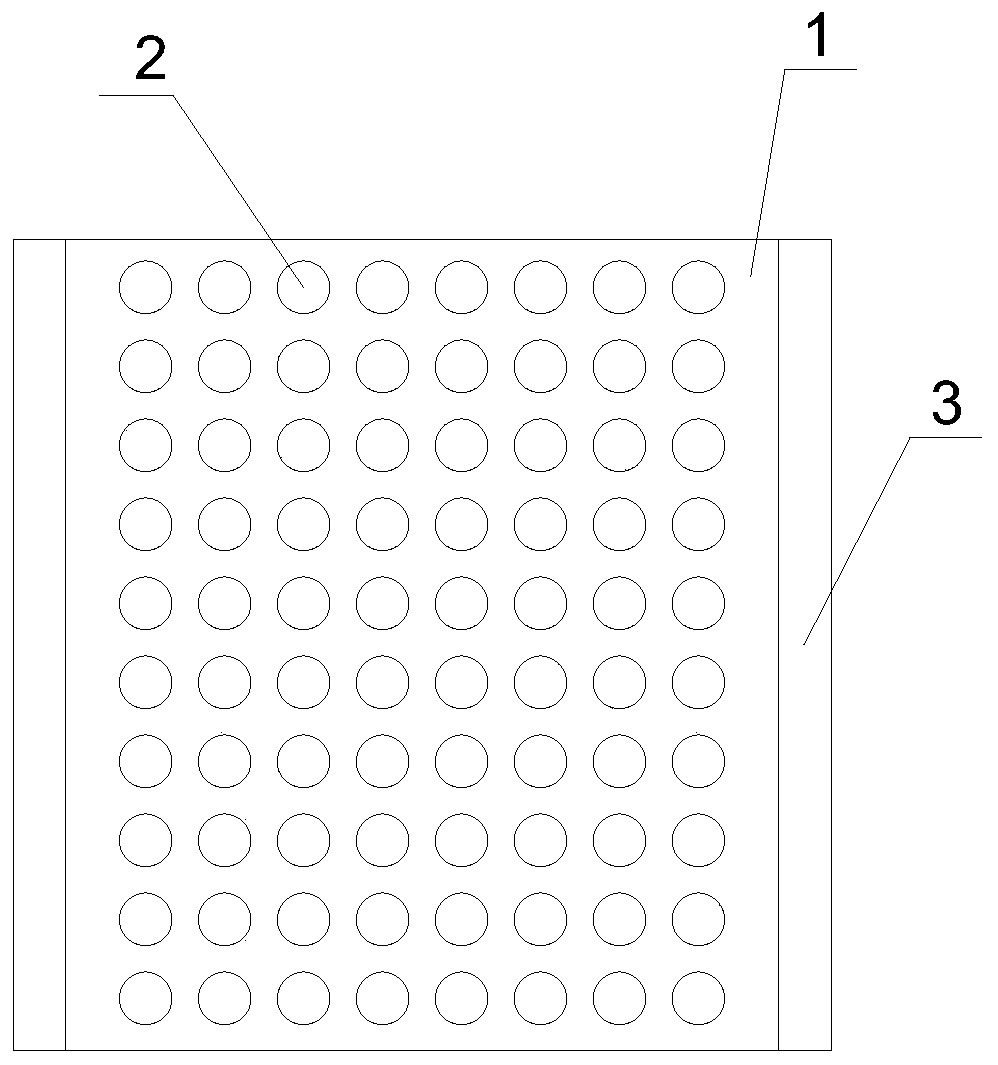

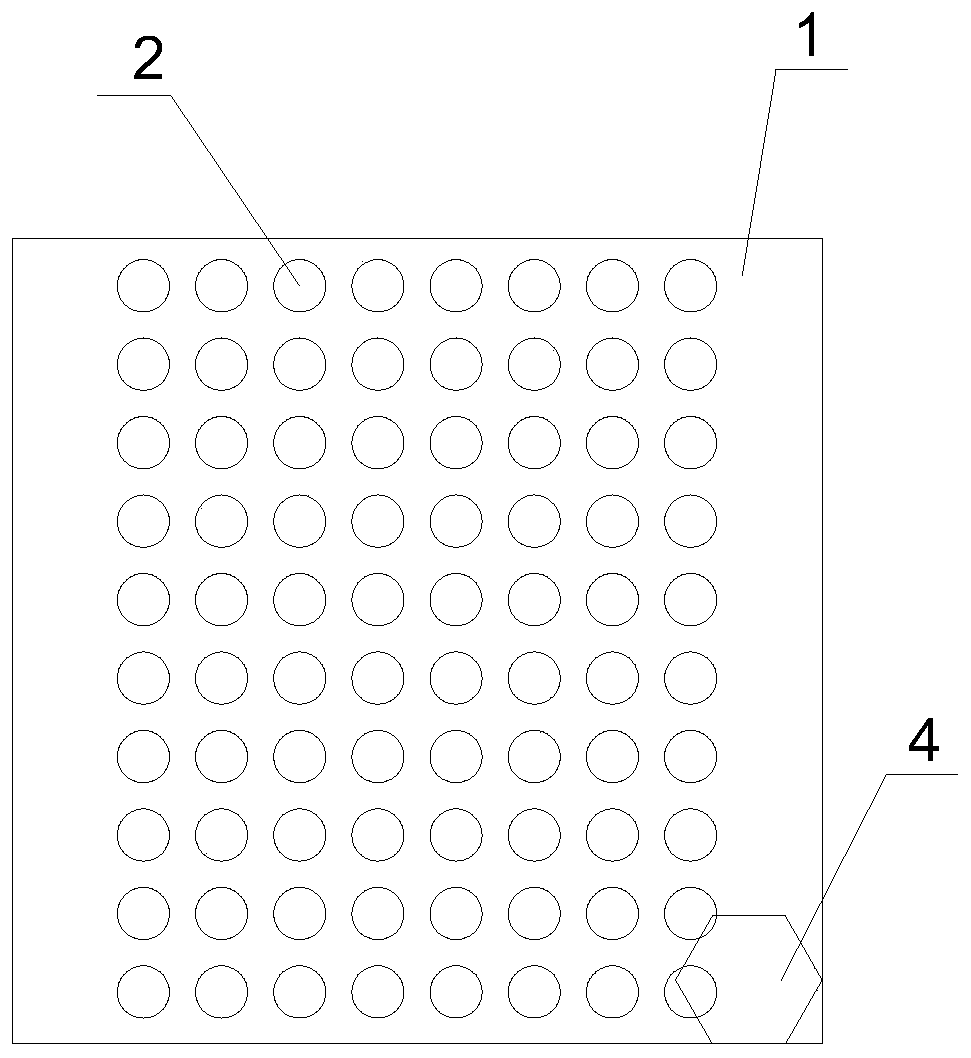

[0023] Step 1: Take a stainless steel substrate 1 with a size of 3cm*3cm and a thickness of 10mm to 30mm, and use a laser to etch out an array of nanoscale ordered pores 2 of uniform size. The diameter of the pores ranges from 200nm to 500nm.

[0024] Step 2: Spray the conductive ink on the substrate to coat a wet film with a thickness of 20 μm to 50 μm, and then form a continuous conductive layer on the surface of the substrate and the inner side of the small hole after drying. Wherein, step 2 specifically includes the following steps:

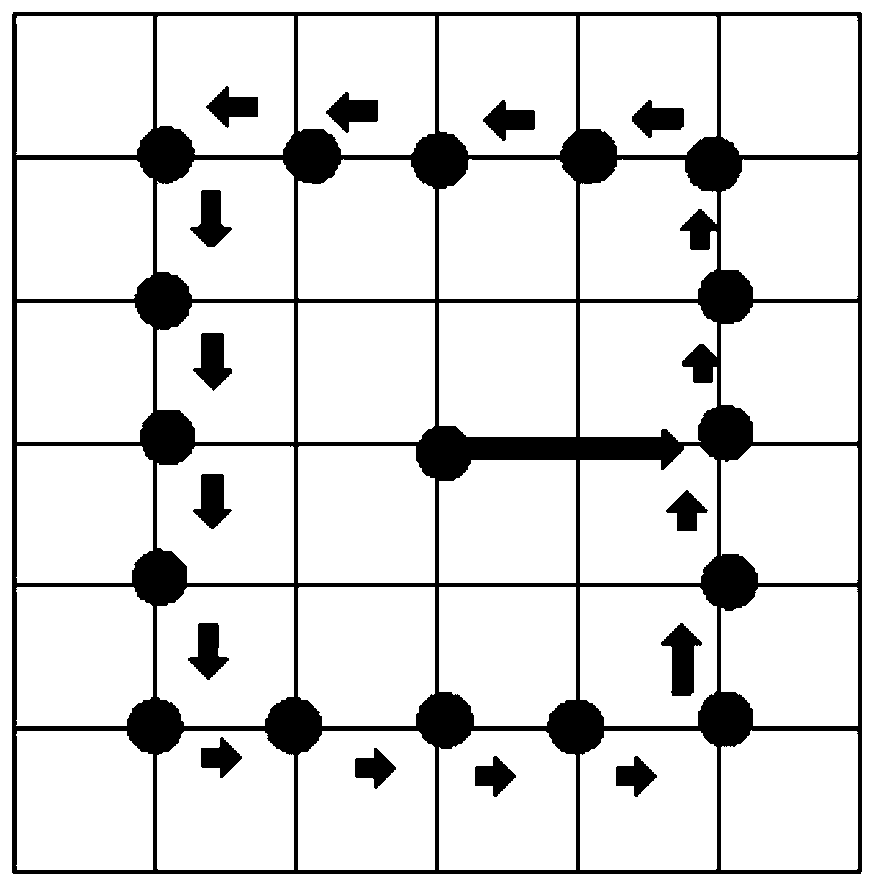

[0025] Step 21: Fix the position of the gun head of the spraying instrument with a bracket, and ensure that the position of the gun head remains unchanged during spraying, and the gun head is perpendicular to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com