Method for preparing display substrate and display substrate

A technology for display substrates and substrates, which is applied in nonlinear optics, instruments, optics, etc., can solve the problem that the preparation method of reflective display substrates cannot be prepared into shapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

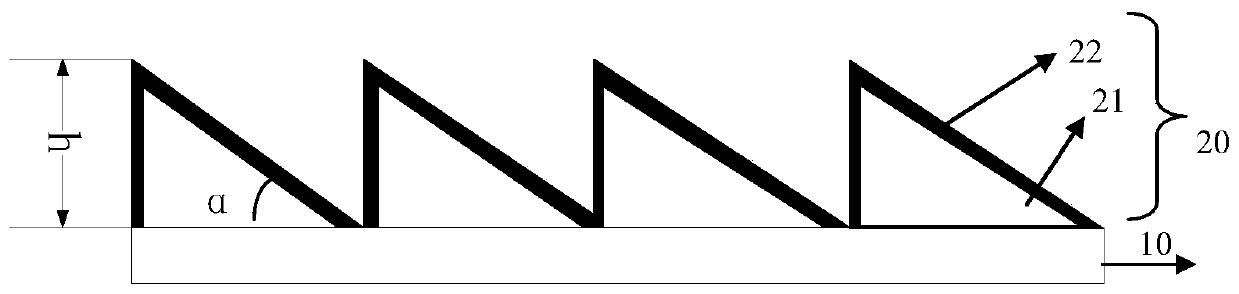

[0033] refer to figure 1 In one aspect, the present invention provides a display substrate, including: a substrate 10 and a reflective layer 20; wherein the reflective layer 20 is disposed on the substrate 10; and the reflective layer includes a plurality of wedge-shaped structures.

[0034] In an embodiment of the present invention, the substrate includes an array substrate.

[0035] In the embodiment of the present invention, the inclined surface of the wedge-shaped structure is a plane or a curved surface, and forms a preset angle α with the substrate.

[0036] In the embodiment of the present invention, the preset included angle α includes: 7°-12°. Preferably, the preset angle α is 9°.

[0037] In an embodiment of the present invention, the height h of the wedge-shaped structure includes: 1 μm-3 μm.

[0038] In the embodiment of the present invention, the reflective layer 20 includes: a resin layer 21 and a reflective layer 22 ; the resin layer 21 is disposed between th...

Embodiment 2

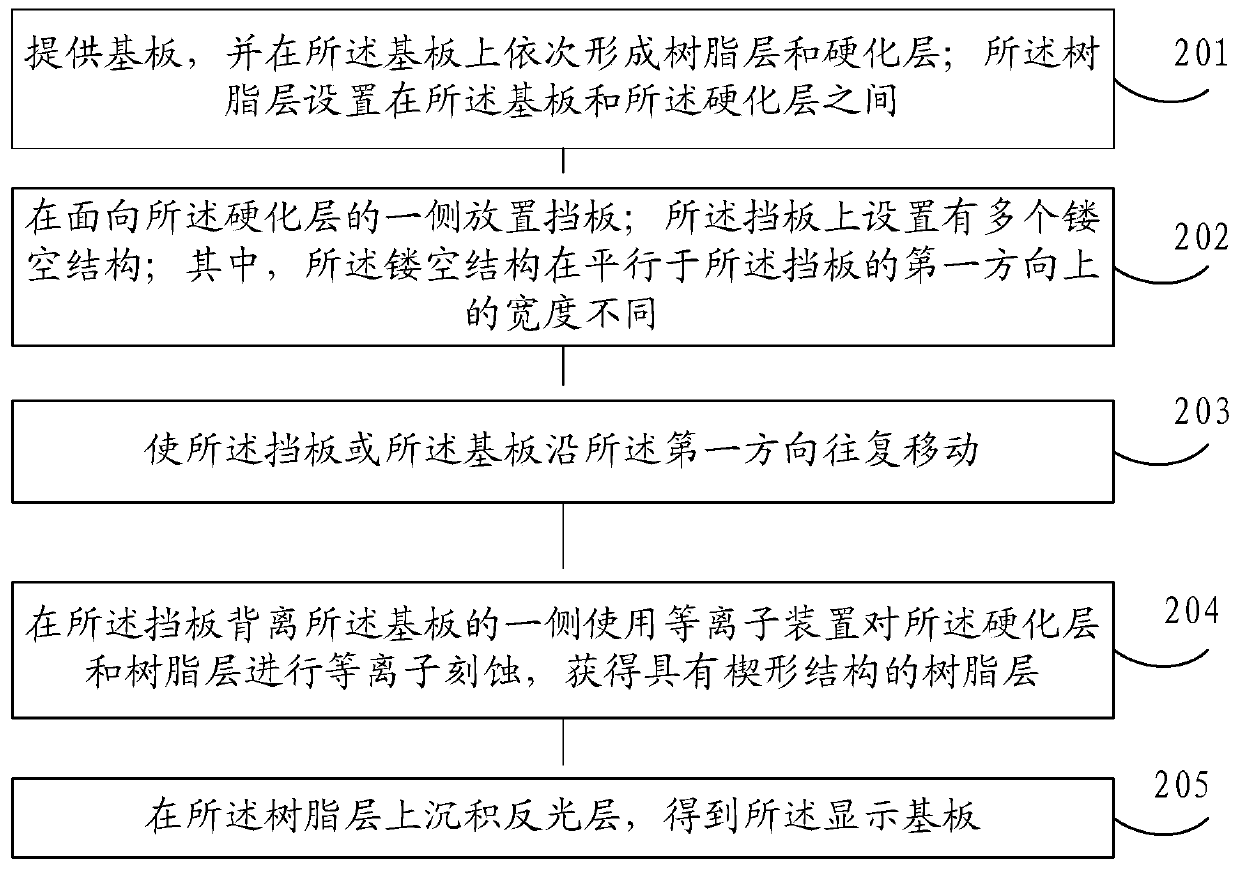

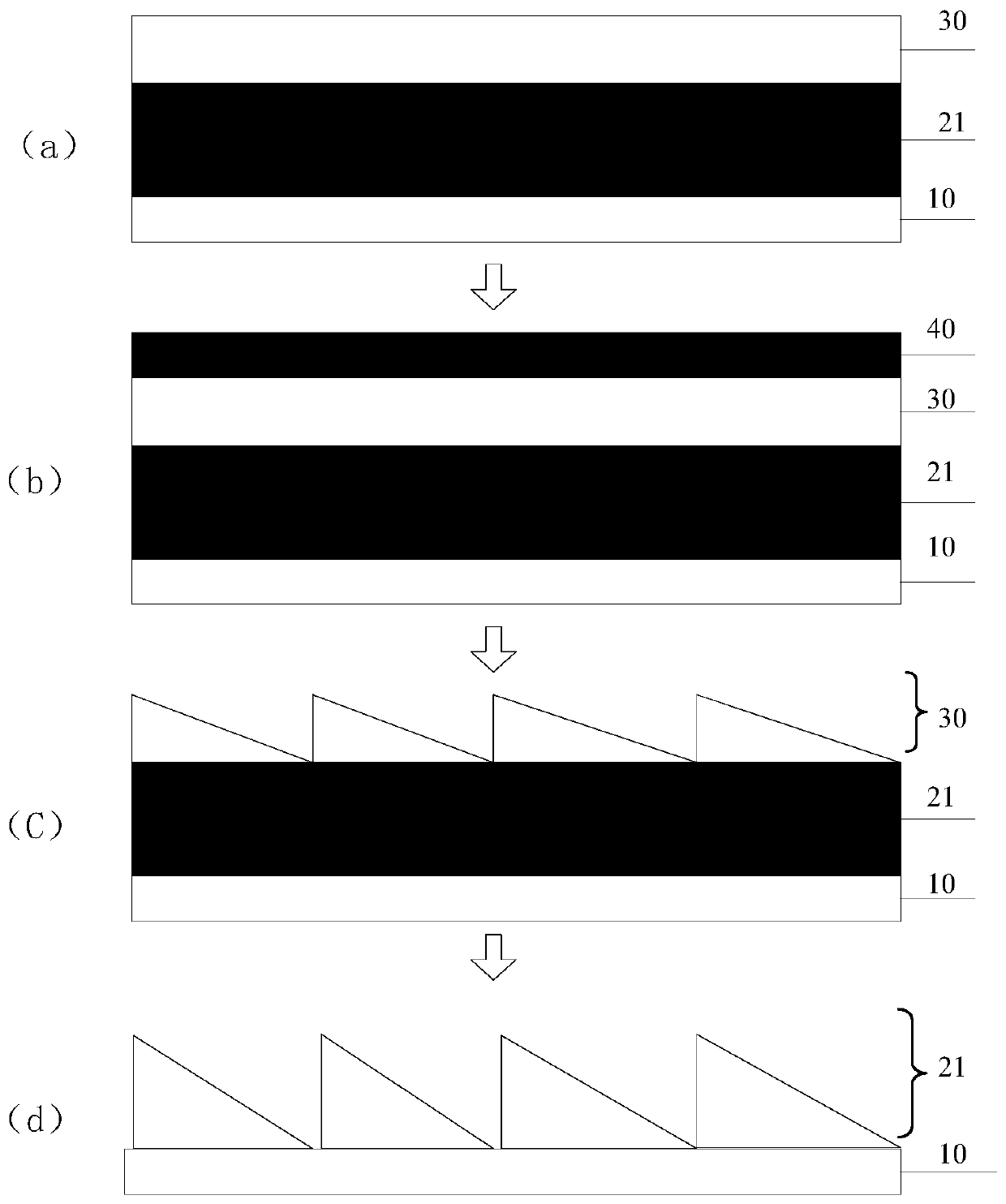

[0042] refer to figure 2 and image 3 An embodiment of the present invention provides a method for preparing a display substrate, including:

[0043] Step 201 , providing a substrate 10 , and sequentially forming a resin layer 21 and a hardened layer 30 on the substrate 10 ; the resin layer 21 is disposed between the substrate 10 and the hardened layer 30 .

[0044] In the embodiment of the present invention, refer to image 3 In (a), the resin layer 21 is coated on the substrate 10, and a hardened layer is deposited on the resin layer 21. The material of the hardened layer 30 includes: silicon dioxide or silicon nitride, preferably silicon dioxide.

[0045] Step 202, placing a baffle 40 on the side facing the hardened layer 30; the baffle 40 is provided with a plurality of hollow structures 41; wherein, the hollow structures 41 are parallel to the first side of the baffle 40 The width in the direction is different.

[0046] In the embodiment of the present invention, ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com