Novel composite electromagnetic shielding latex paint and preparation thereof

An electromagnetic shielding, composite technology, applied in the direction of coating, chemical instruments and methods, synthetic resin layered products, etc., to achieve the effects of good applicability and field construction, easy operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

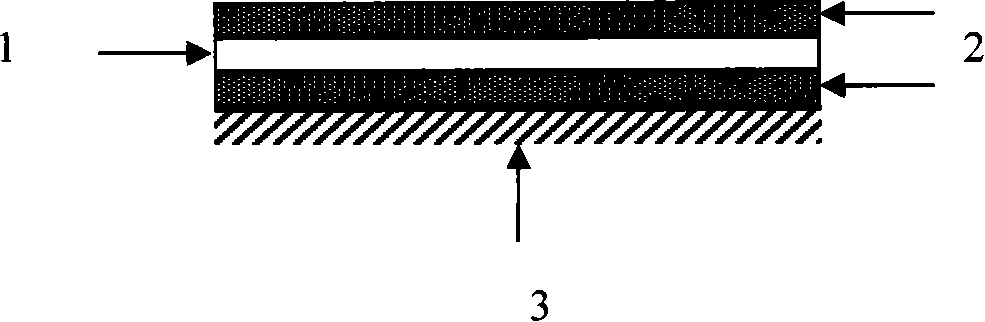

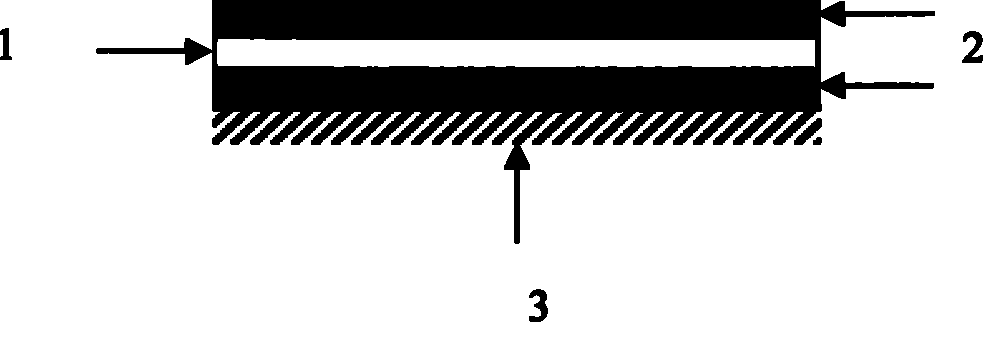

Image

Examples

Embodiment 1

[0042] The technological process and process parameters of the present embodiment are as follows:

[0043] 1. Ingredients

[0044] The formula (parts by weight) of the conductive layer coating is as follows:

[0045] Pure acrylate copolymer emulsion 50 parts

[0046] 30 parts of conductive nickel powder with a particle size of micron and a purity of more than 99.7%

[0047] Ethylene glycol butyl ether acetate 3 parts

[0048] 1.5 parts of hydroxyethyl cellulose

[0049] Inorganic bentonite 1.5 parts

[0050] 14 parts of purified water

[0051] The formula (parts by weight) of insulating interlayer paint is as follows:

[0052] Pure acrylate copolymer emulsion 90 parts

[0053] Ethylene glycol butyl ether acetate 4 parts

[0054] 1 part hydroxyethyl cellulose

[0055] 5 parts purified water

[0056] 2. Preparation of coating

[0057] (1) Preparation of the conductive layer part

[0058] Dry the originally prepared micron-sized nickel powder at a drying temperature of ...

Embodiment 2

[0065] The technological process and process parameters of the present embodiment are as follows:

[0066] 1. Ingredients

[0067] The formula (parts by weight) of the conductive layer coating is as follows:

[0068] Styrene-acrylate copolymer emulsion 55 parts

[0069] Micron-sized conductive nickel powder 30 parts

[0070] Ethylene glycol butyl ether acetate 3 parts

[0071] Hydroxyethyl cellulose 0.5 parts

[0072] Inorganic bentonite 1.5 parts

[0073] 10 parts of purified water

[0074] The formula (parts by weight) of insulating interlayer paint is as follows:

[0075] Styrene-acrylate copolymer emulsion 90 parts

[0076] Ethylene glycol butyl ether acetate 3 parts

[0077] 31 parts of hydroxyethyl cellulose

[0078] 7 parts purified water

[0079] 2. Preparation of coating

[0080] (1) Preparation of the conductive layer part

[0081] Dry the originally prepared micron-sized nickel powder at a drying temperature of 70°C, and then mix styrene-acrylate copolym...

Embodiment 3

[0088] The technological process and process parameters of the present embodiment are as follows:

[0089] 1. Ingredients

[0090] The formula (parts by weight) of the conductive layer coating is as follows:

[0091] Pure acrylate copolymer emulsion 45 parts

[0092] Micron nickel powder 35 parts

[0093] 2 parts propylene glycol butyl ether

[0094] Methyl hydroxyethyl cellulose 1.0 parts

[0095] Inorganic bentonite 2 parts

[0096] 15 parts of purified water

[0097] The formula (parts by weight) of insulating interlayer paint is as follows:

[0098] Styrene-acrylate copolymer emulsion 91 parts

[0099] 2 parts propylene glycol butyl ether

[0100] 3 parts methyl hydroxyethyl cellulose

[0101] 5 parts purified water

[0102] 2. Preparation of coating

[0103] (1) Preparation of the conductive layer part

[0104] Dry the originally prepared micron-sized nickel powder, the optimal drying temperature is 60°C, and then mix pure acrylate copolymer emulsion, propylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com