Method of manufacturing a photovoltaic module

A photovoltaic module and photovoltaic cell technology, applied in photovoltaic power generation, chemical instruments and methods, electronic equipment, etc., can solve the problems of time-consuming manufacturing and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

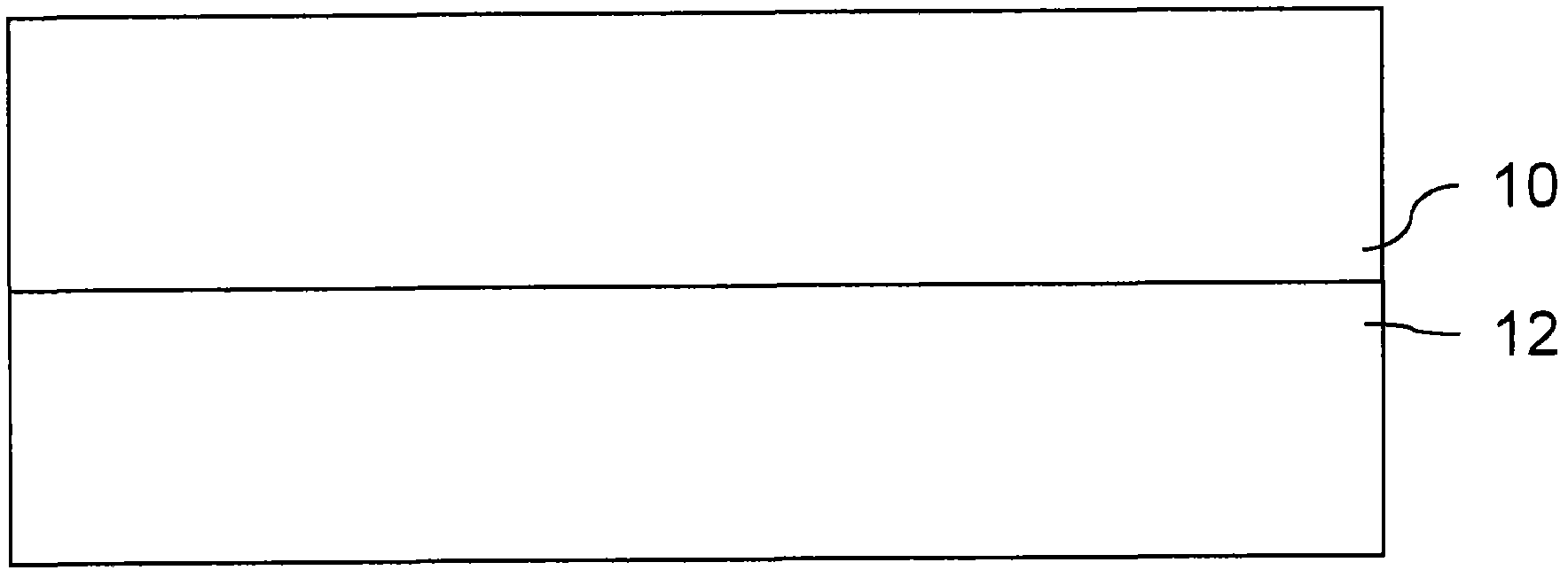

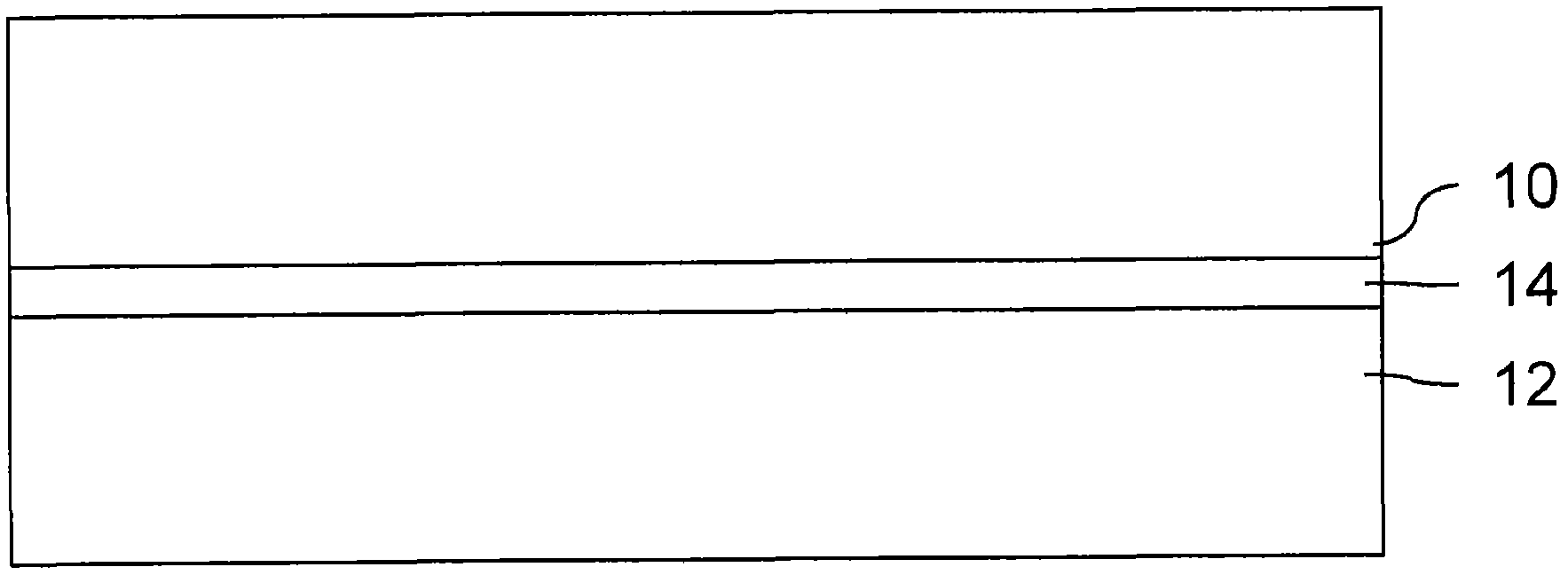

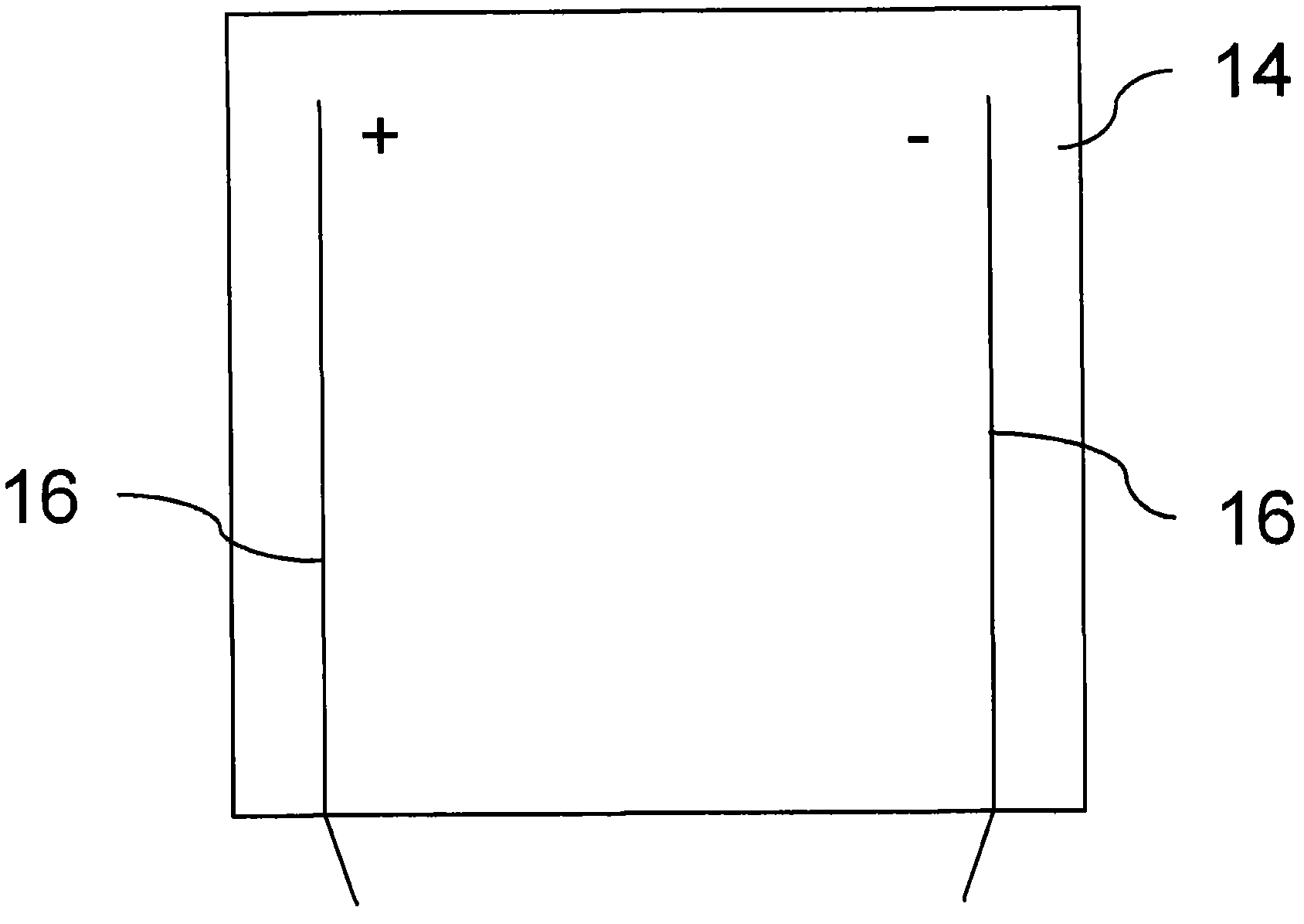

[0029] figure 1 A schematic diagram is shown of a photovoltaic module according to a first embodiment of the invention comprising a front end part 10 and a rear end part 12 connected to the photovoltaic module. The front end part 10 and the rear end part 12 are pre-assembled to a photovoltaic panel or photovoltaic module, respectively, before interconnection. The front part 10 of the photovoltaic module preferably includes a front cover element, photovoltaic cells and interconnections. The photovoltaic cell is preferably a thin film photovoltaic cell capable of converting radiation into electrical energy. The front end part 10 is assembled by placing photovoltaic cells on the front cover element. The front cover element can be a transparent material such as glass. Preferably, the rear part 12 of the photovoltaic module is assembled at the same time, wherein at least the rear reflector, the junction box and the rear cover element are connected to each other. The back cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com