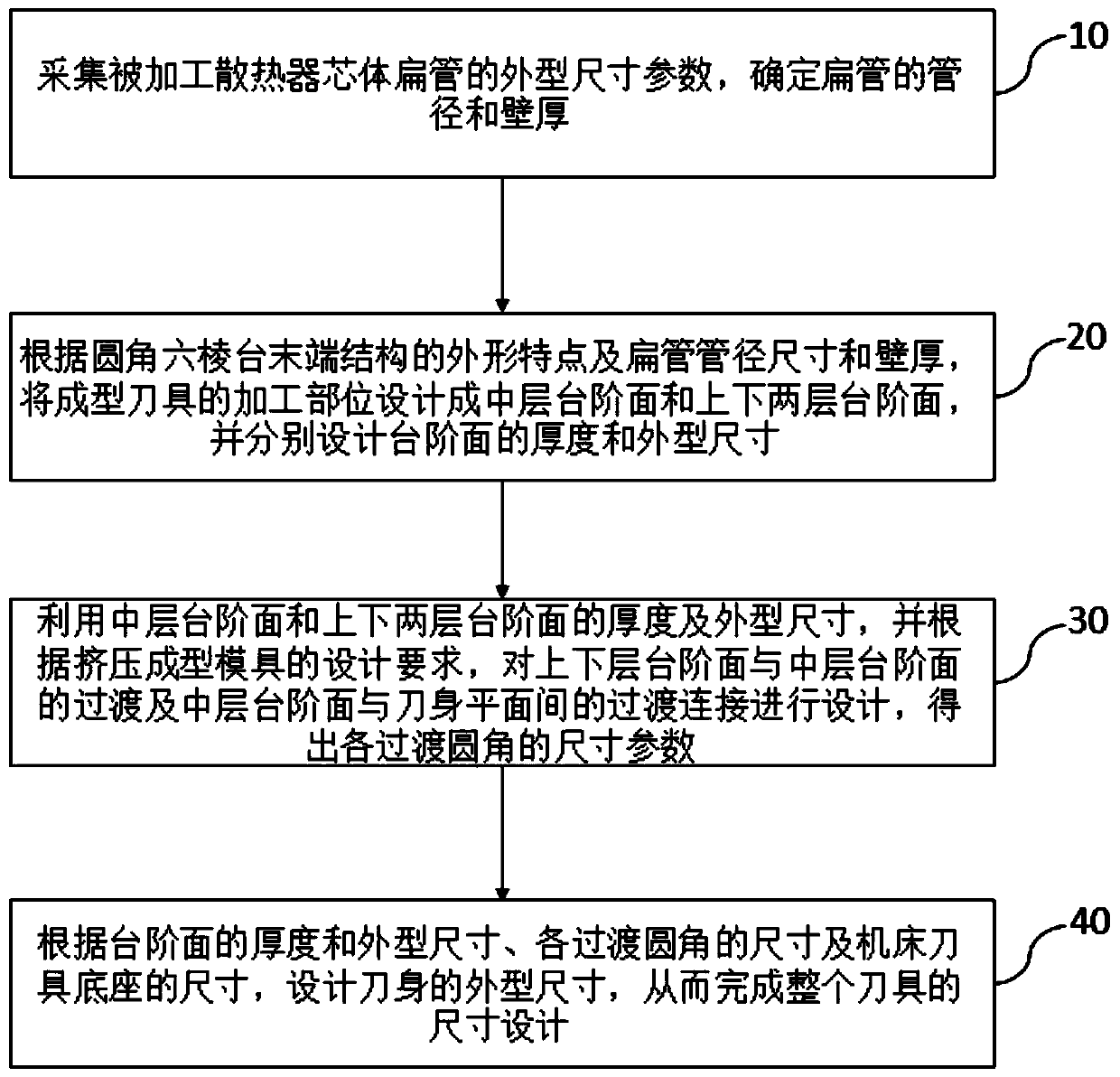

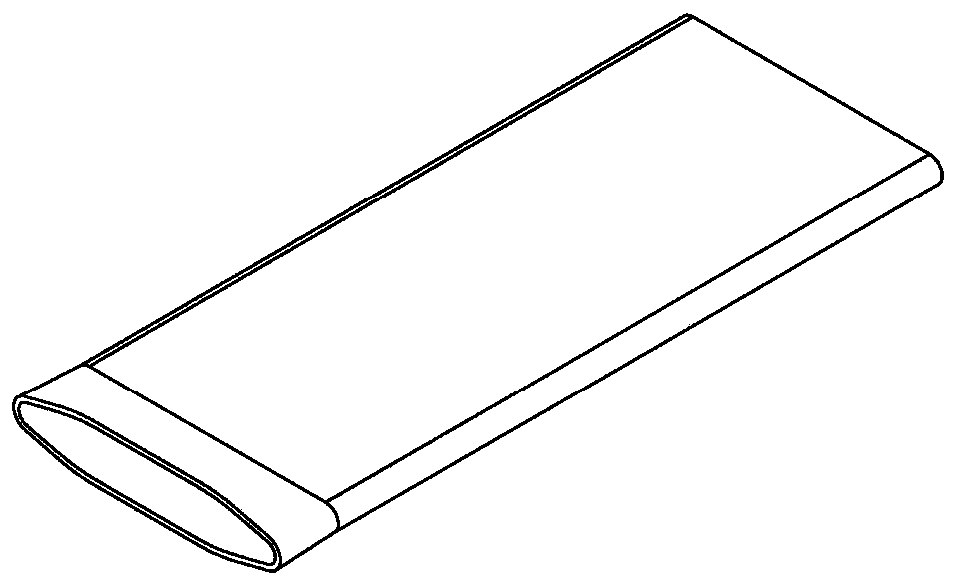

Design method of forming cutter for any-pipe-diameter tail end structure of automobile radiator core

A technology of automobile radiator and forming tool, which is applied in instrument, calculation, special data processing application, etc., can solve the problems of fatigue cracking damage, small width gap, failure, etc., and achieve smooth surface transition, clear design steps, and step height difference. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] According to the technical solution of the present invention, without changing the spirit of the present invention, those skilled in the art can propose multiple structural modes and production methods of the present invention. Therefore, the following specific embodiments and drawings are only specific descriptions of the technical solution of the present invention, and should not be regarded as the entirety of the present invention or as a limitation or restriction on the technical solution of the present invention.

[0021] Below in conjunction with embodiment and attached figure 1 The present invention is described in further detail:

[0022] A non-contact tube-side fluid temperature measurement method based on the temperature measurement of the outer wall of the pipeline described in the present invention, the specific steps include:

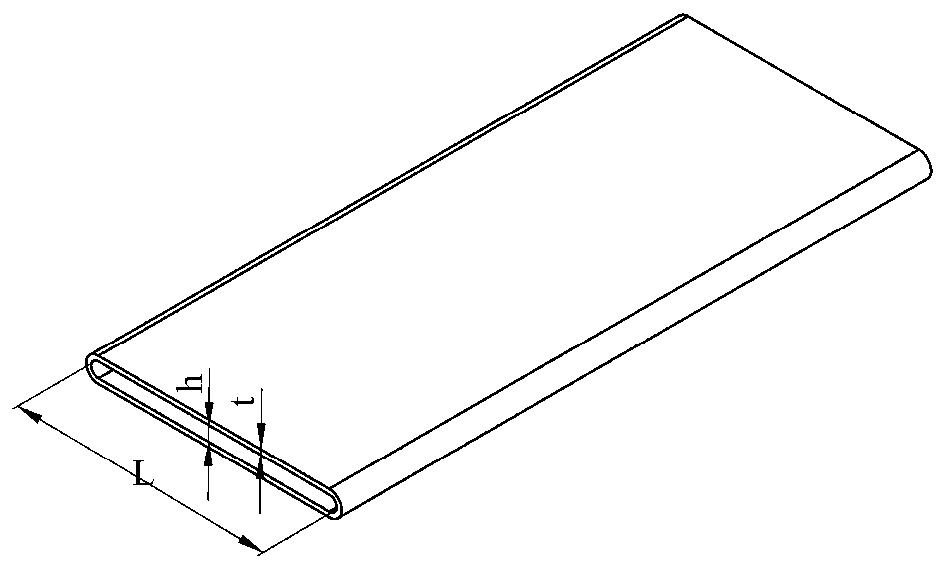

[0023] Step 10, collect the external dimension parameters of the processed radiator core flat tube, and determine the diameter and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com