A linear piezoelectric motor and its driving method

A piezoelectric motor, linear technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of complex design circuit of ultrasonic motor driver, stator piezoelectric material Fatigue damage, the motor deviates from the working resonance frequency and other problems, to avoid negative effects, high motor motion precision, and large output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, the present invention will be further described in detail with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

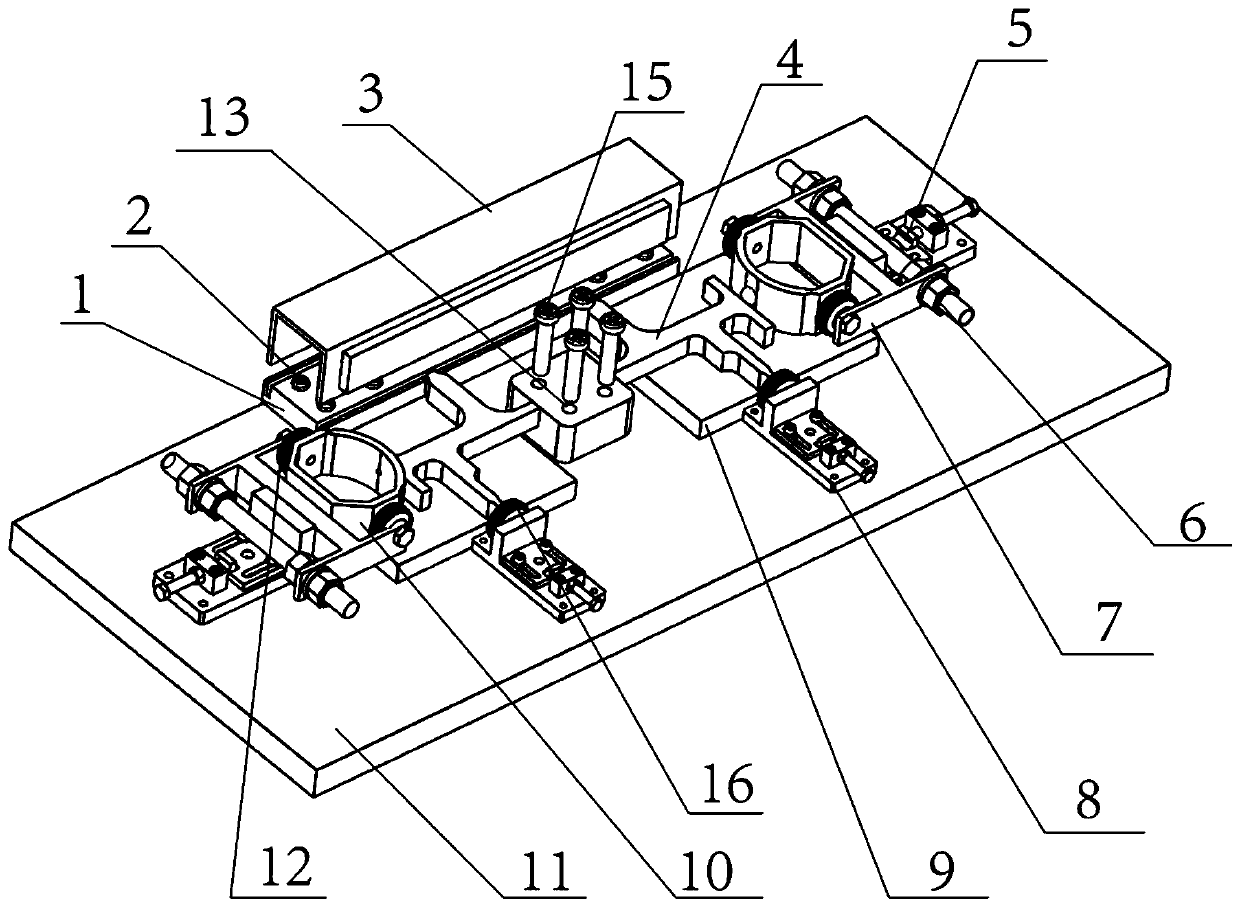

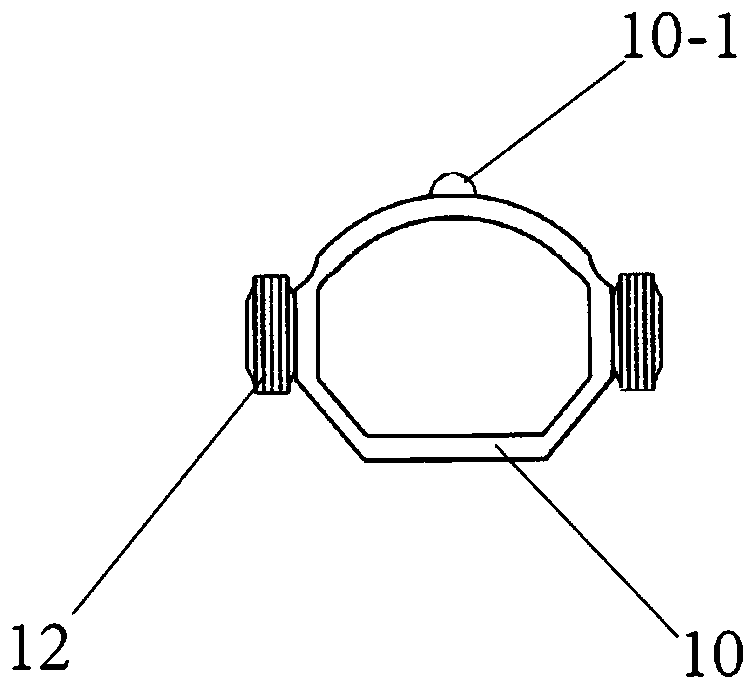

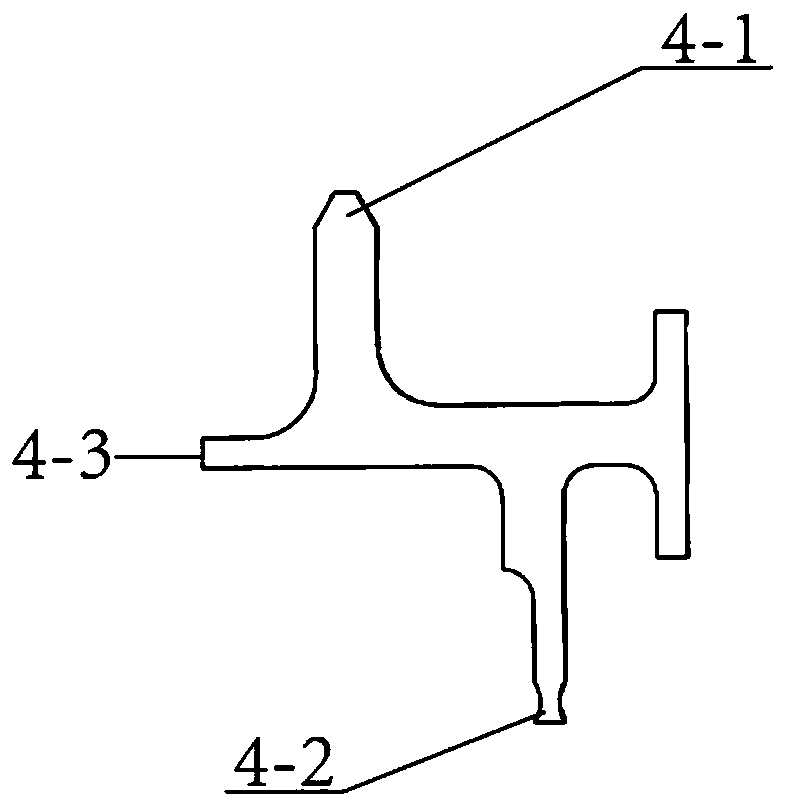

[0034] This embodiment provides a linear piezoelectric motor operating based on a non-resonant mode. The motor includes a bottom plate, and a mover, a fixed block, and a stator arranged on the bottom plate. See Figure 1-4 , The various components involved in the figure are: slider fixing seat 1, slider fixing seat bolt 2, mover slider 3, contact rod 4, horizontal pre-tightening mechanism 5, pre-tightening clamping bolt 6, pre-tightening combination rod 7. The vertical pre-tensioning mechanism 8, the stator fixing plate 9, the deformable bracket 10, the bottom plate 11, the second piezoelectric stack 12, the fixing block 13, the fixing block bolt 15, and the first piezoelectric stack 16.

[0035] In this embodiment, the mover includes a slider fixing base 1, a slider fixing base bolt 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com