Head rolling machine

A head mill and roll technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of no safety protection of the roll, efficient operation of the head mill, accidents, etc., to prevent operation accidents, improve efficiency, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

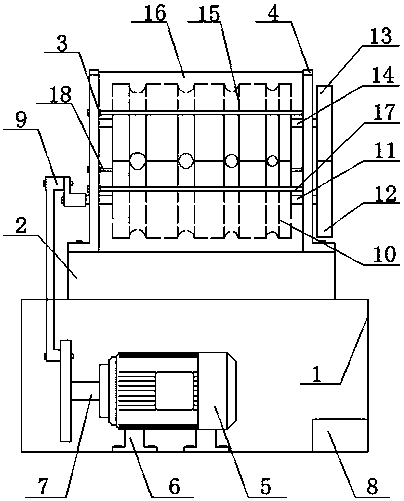

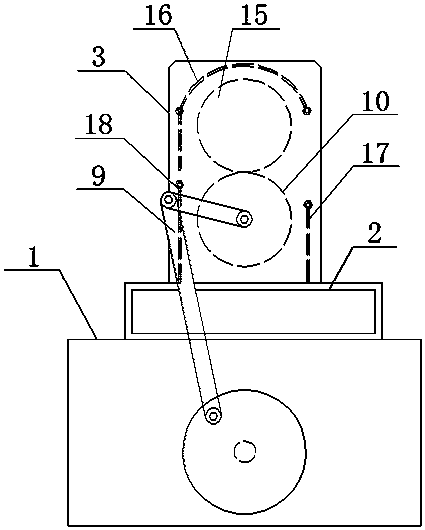

[0017] Combine below figure 1 with figure 2 Shown is a further description of a heading machine of the present invention.

[0018] A rolling head machine, comprising a motor 5, a roll 10, a roll 15, a gear 12, a gear 13 and a base 1, characterized in that: the base 1 is provided with a safety seat 2, and the safety seat 2 is provided with a left fixing seat 3 and a right fixing seat 4, the motor 5 is arranged on the base 1, the front end of the motor 5 is provided with a connecting shaft 7, and the front end of the connecting shaft 7 is provided with an eccentric crank rocker mechanism 9 The eccentric crank and rocker mechanism 9 is connected with a roll shaft 11, the end of the roll shaft 11 is provided with a gear 12, the gear 12 is connected with a gear 13 and the front end of the gear 13 is provided There are two roll shafts 14, the roll shaft one 11 and the roll shaft two 14 are respectively provided with a roll one 10 and a roll two 15 respectively. The roll shaft one 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com