Welding device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

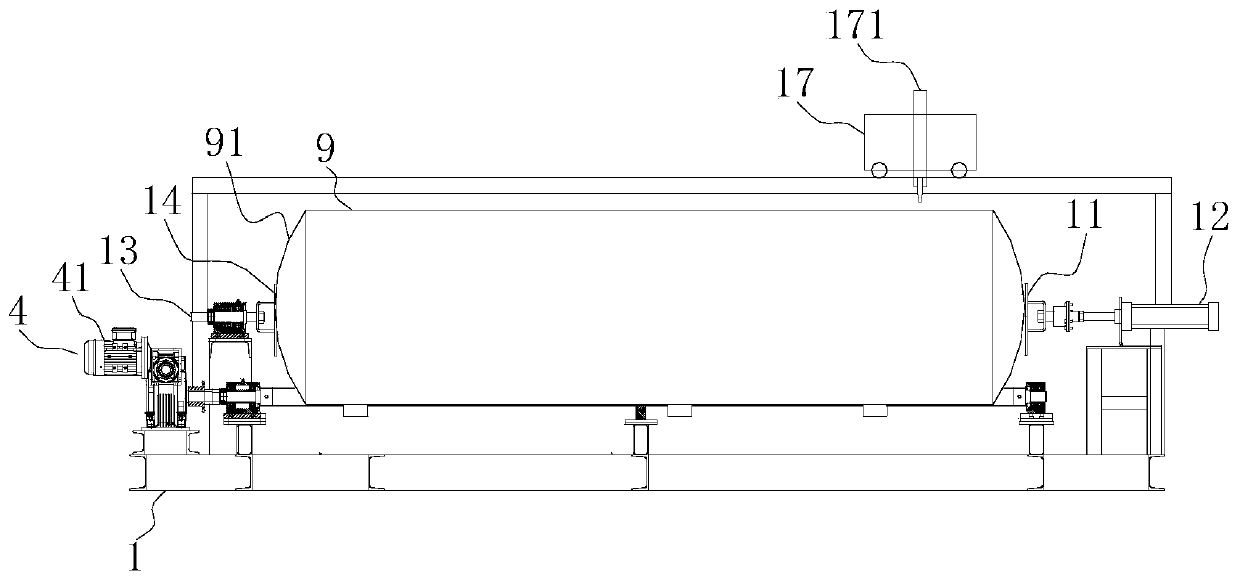

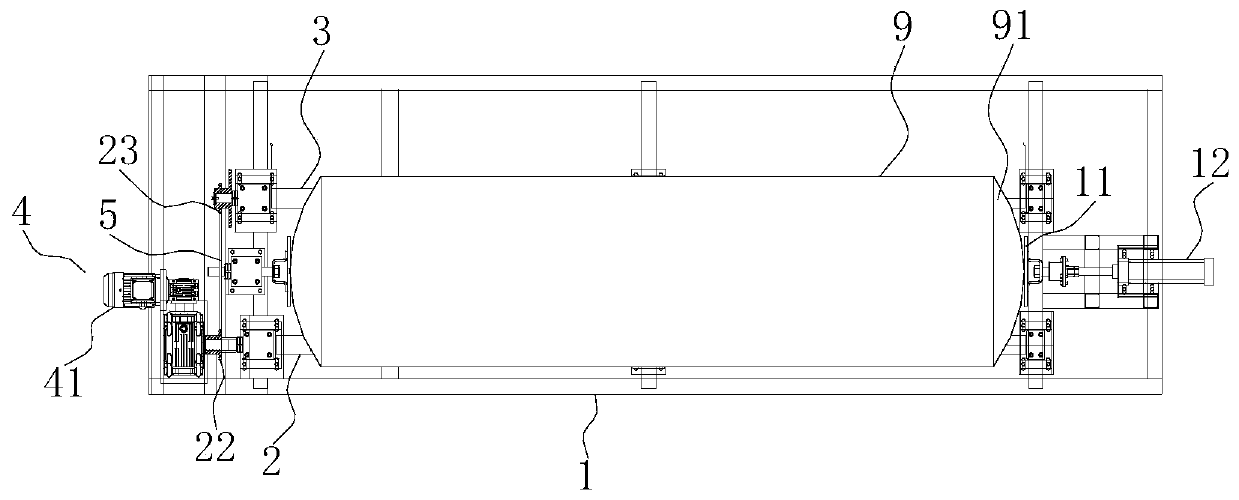

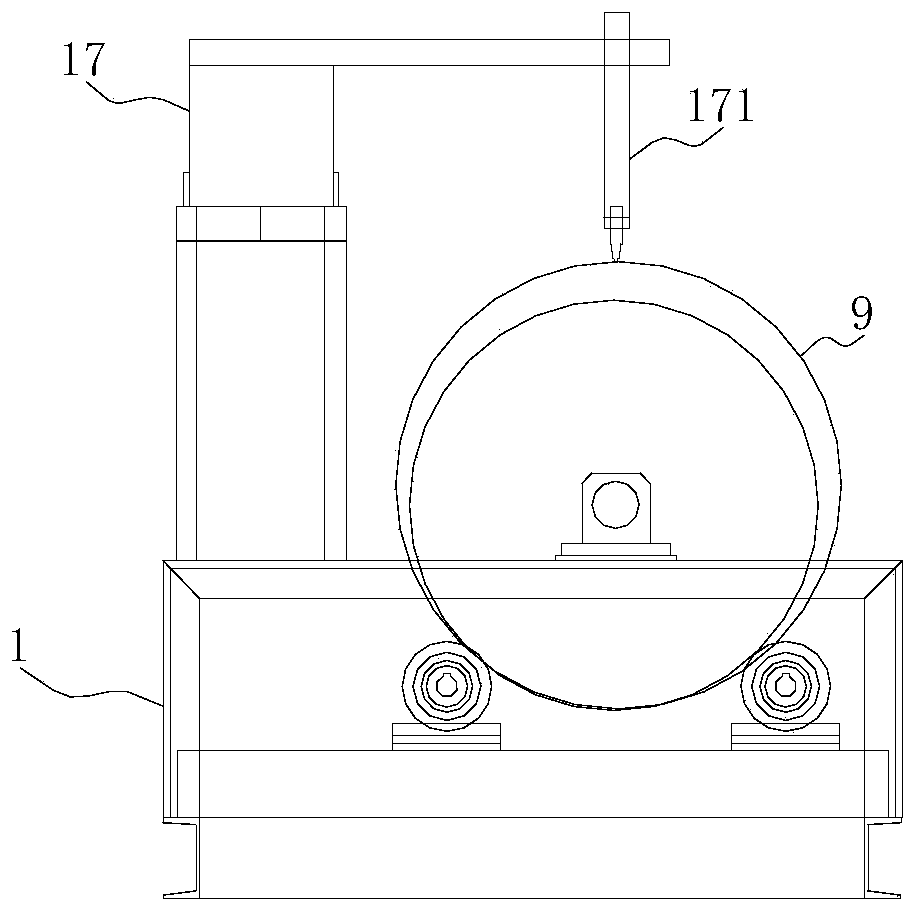

[0035] Embodiment: a kind of welding device, as figure 1 , figure 2 Shown, comprise frame 1, support shaft one 2 and support shaft two 3 are rotatably connected on frame 1, support shaft one 2 and support shaft two 3 are parallel to each other, on the support shaft one 2, how many A support wheel one 21, a plurality of support wheels two 31 are fixed on the support shaft two 3. The frame 1 is fixed with a power part 4 for driving the rotation of the support shaft one 2 and the support shaft two 3, the power part 4 is a reduction motor 41, and the output shaft of the reduction motor 41 is connected with the support shaft one 2, and the support shaft one 2 is fixed with a sprocket one 22, and the supporting shaft two 3 is fixed with a sprocket two 32, and a chain 5 for transmitting power is sleeved between the sprocket one 22 and the sprocket two 32. When reduction motor 41 drives support shaft one 2 to rotate, support shaft one 2 can also drive support shaft two 3 to rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com