Batch attachment method for electronic paper

An electronic paper, paper batch technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of long indwelling time, low production capacity, low efficiency, etc., to reduce the indwelling time and the finished product. The effect of defect rate and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Such as Figure 1 to Figure 9 As shown, a method for attaching electronic paper in batches comprises the following steps:

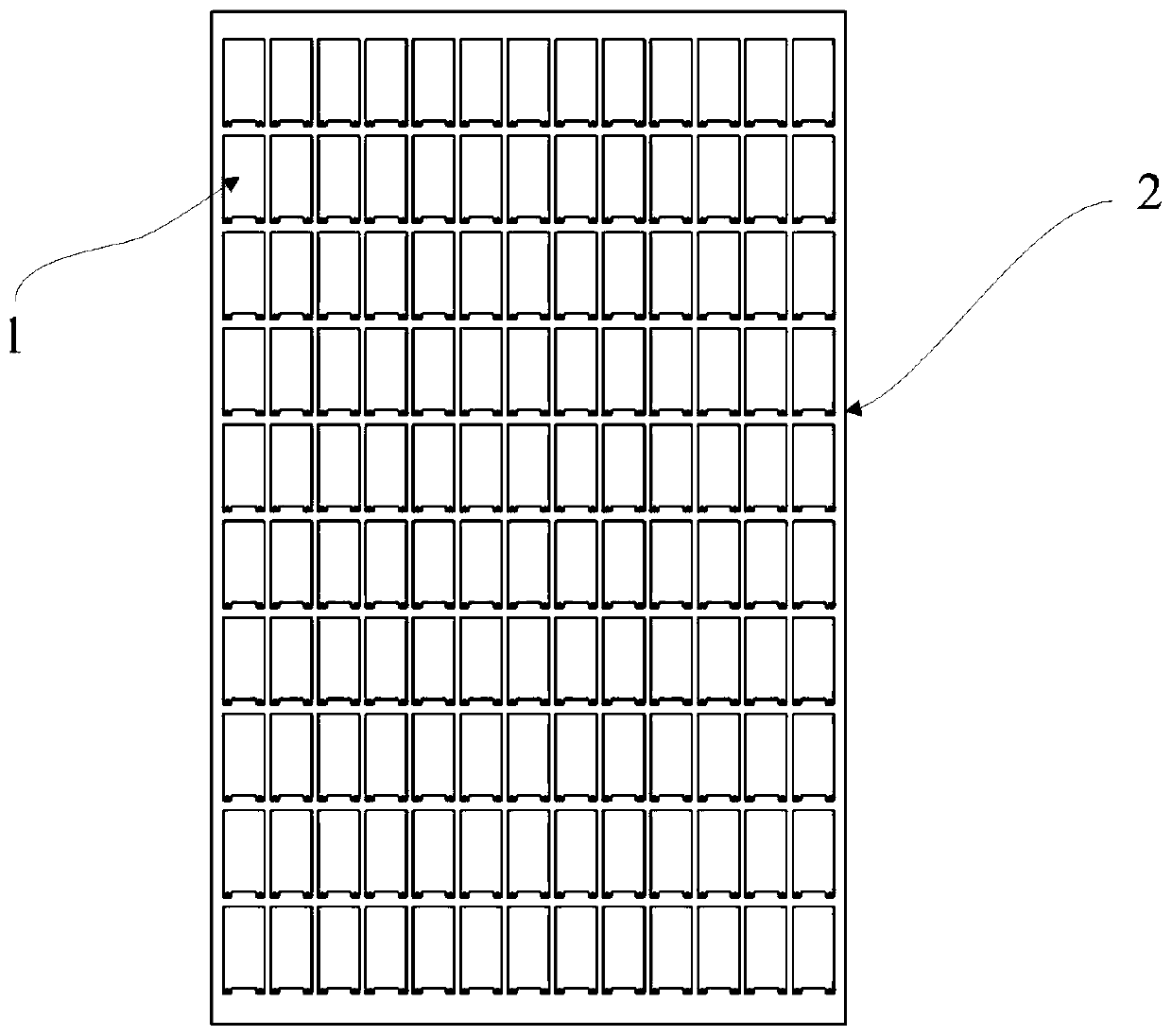

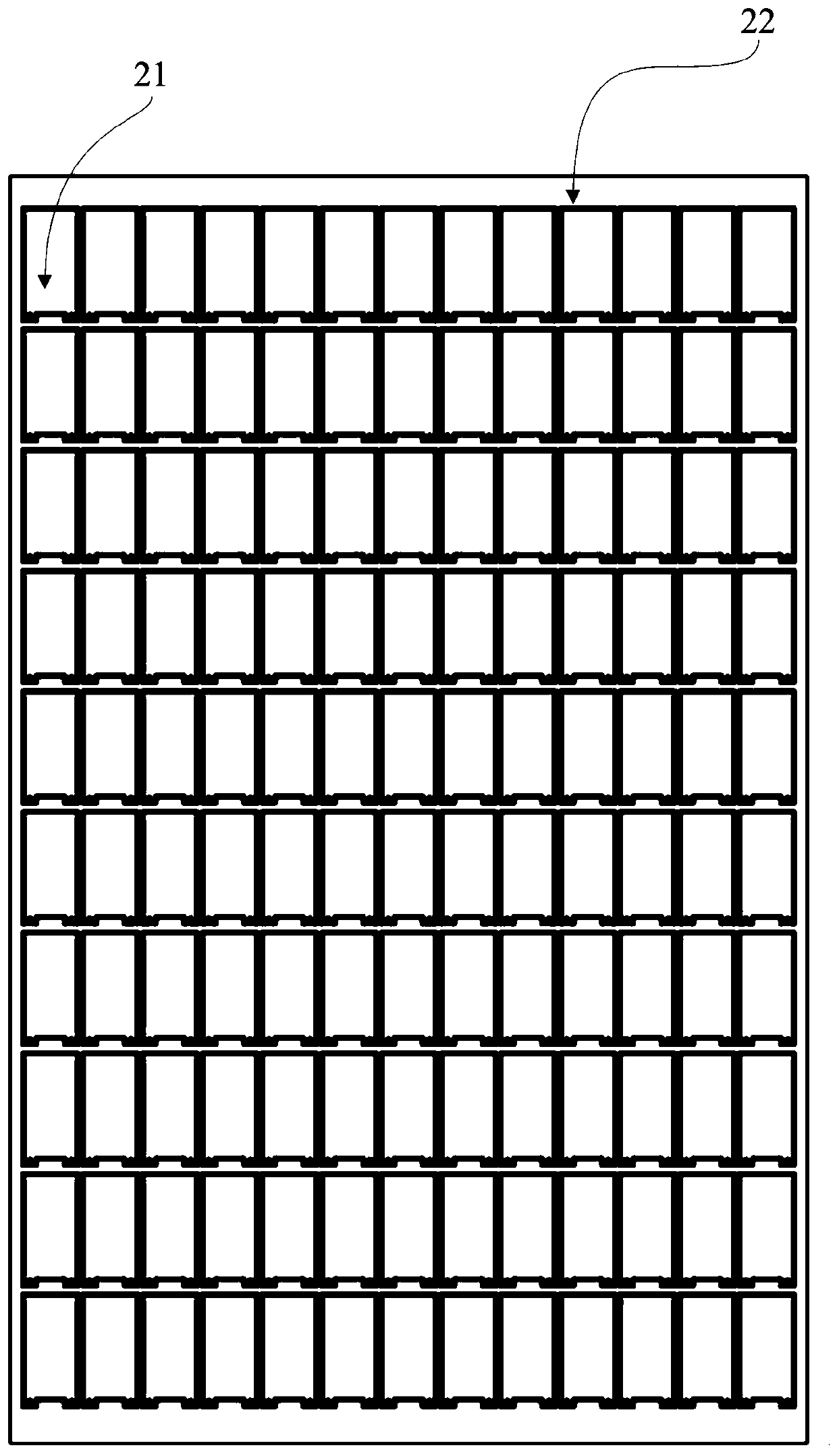

[0030] S1. Bonding the original material: the electronic paper original material (large sheet) and the waterproof protective film original material (large sheet) are bonded together to form the substrate 3, and the waterproof protective film original material is located on the upper side of the electronic paper original material; The paper raw material is used to cut out multiple small pieces of electronic paper 1, and the waterproof protective film raw material is used to cut out multiple small pieces of waterproof protective film 2;

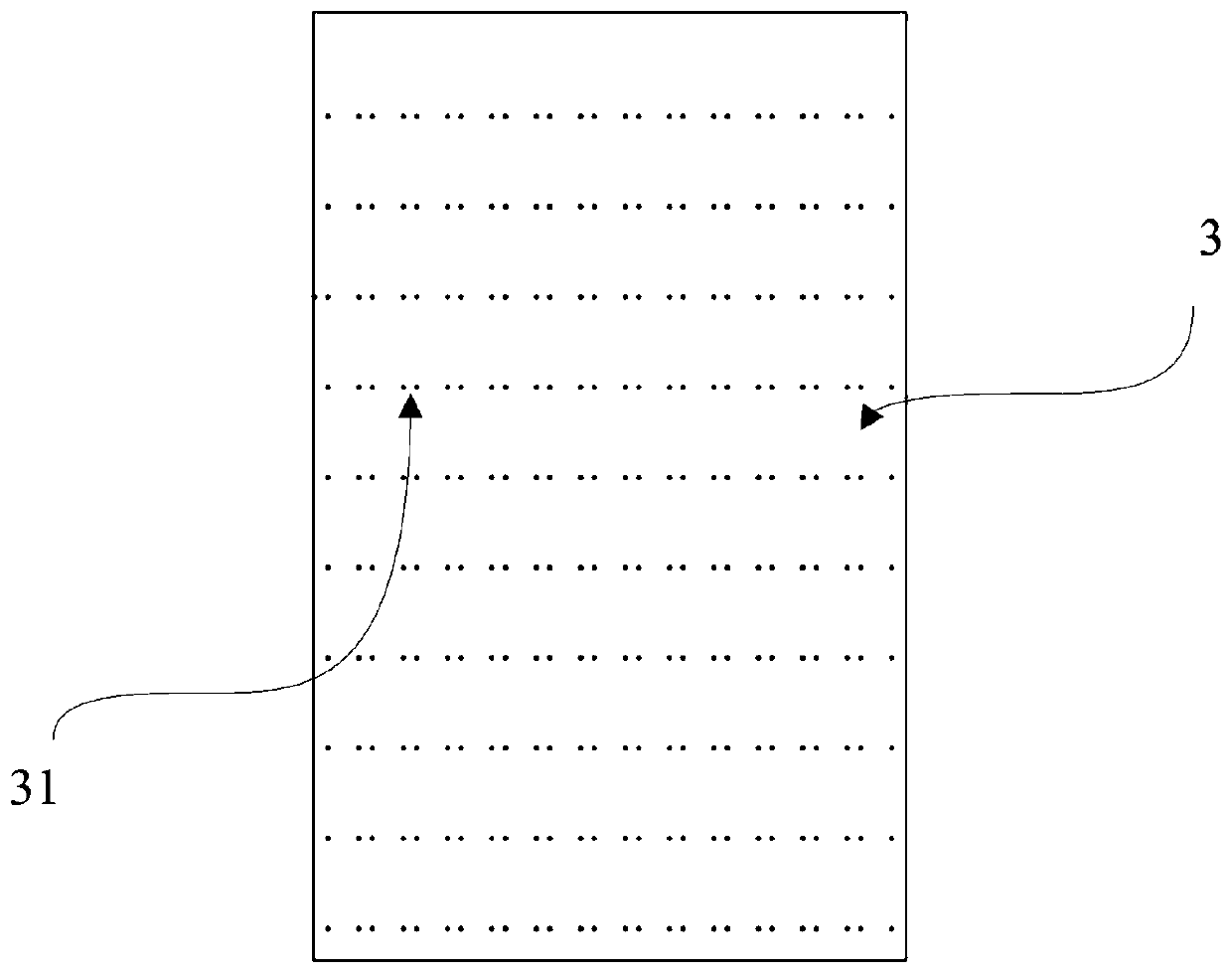

[0031] S2. Cutting earholes: using laser to cut multiple earholes 31 on the base material 3, the multiple earholes 31 are arranged in rows and run through the base material 3, and then the base material is cleaned;

[0032] S3. Cutting the outline of the electronic paper: Turn over the substrate 3 so that one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com