Pantograph head of ring shaft rotary electric traction locomotive

An electric traction and pantograph technology, applied in the field of rail transit, can solve the problems of low utilization rate of skateboards, low utilization rate of skateboard materials, and small contact area for current, so as to improve utilization rate and service life, and improve aerodynamics. The effect of improving the stability of current flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

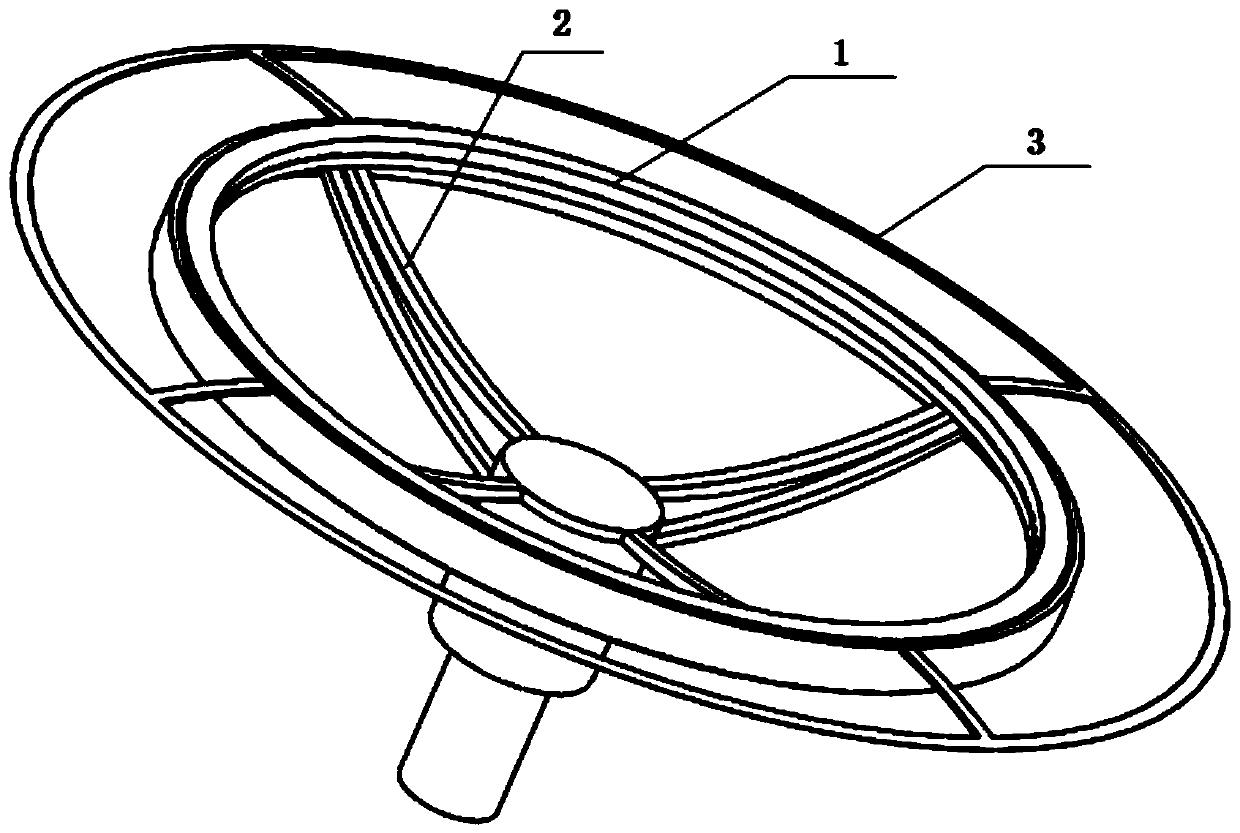

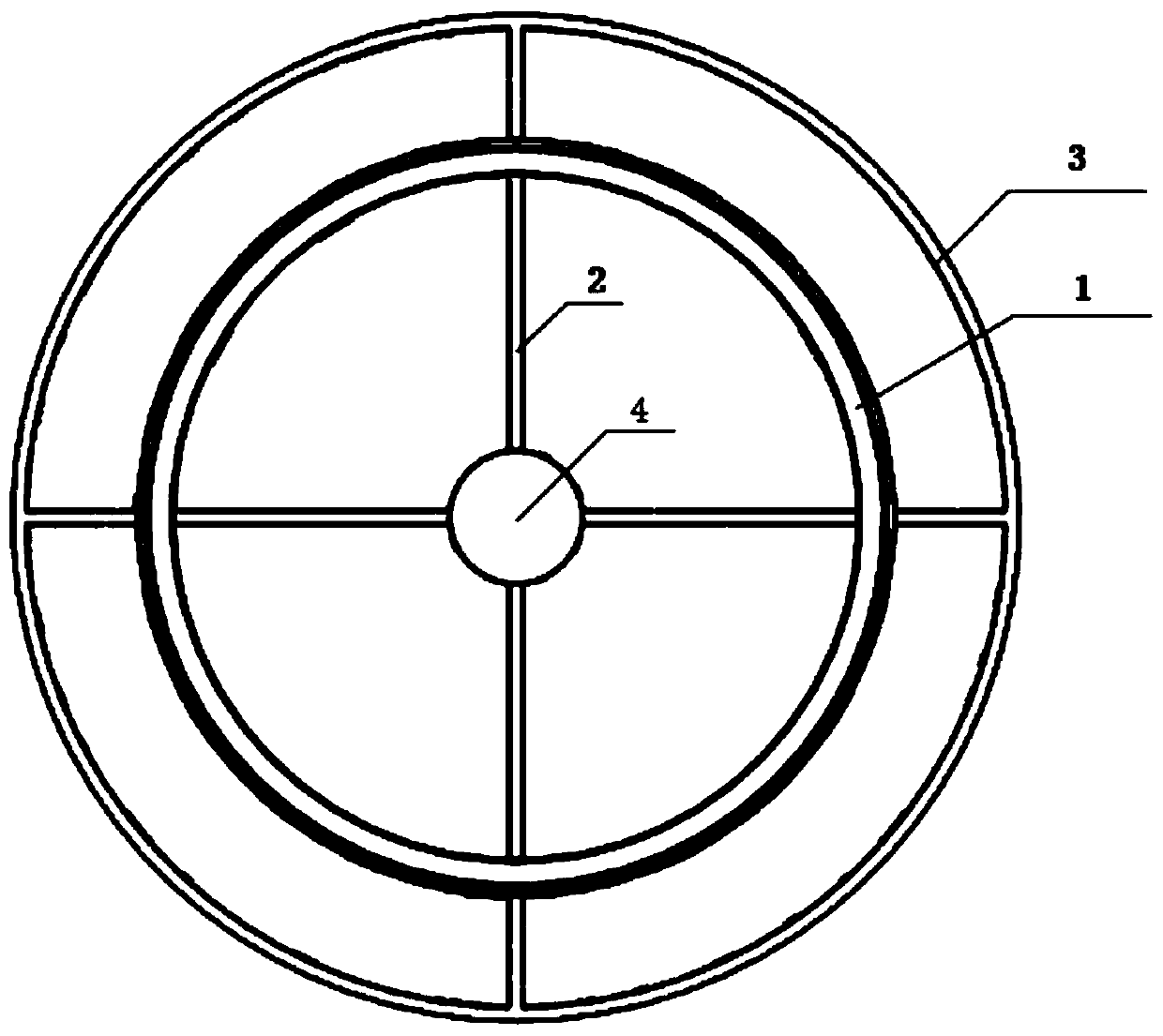

[0023] In the accompanying drawings, the part names corresponding to the reference signs are as follows:

[0024] 1—Annular skateboard, 2—Skateboard bracket, 3—Loop bracket, 4—Rotating shaft, 5—Insulation layer (that is, insulation board), 6—Screw, 7—Shell, 8—Bearing, 9—Copper sheet, 10— Electric brush, 11—spring, 12—insulating plate, 13—power transmission line, 14—contact wire.

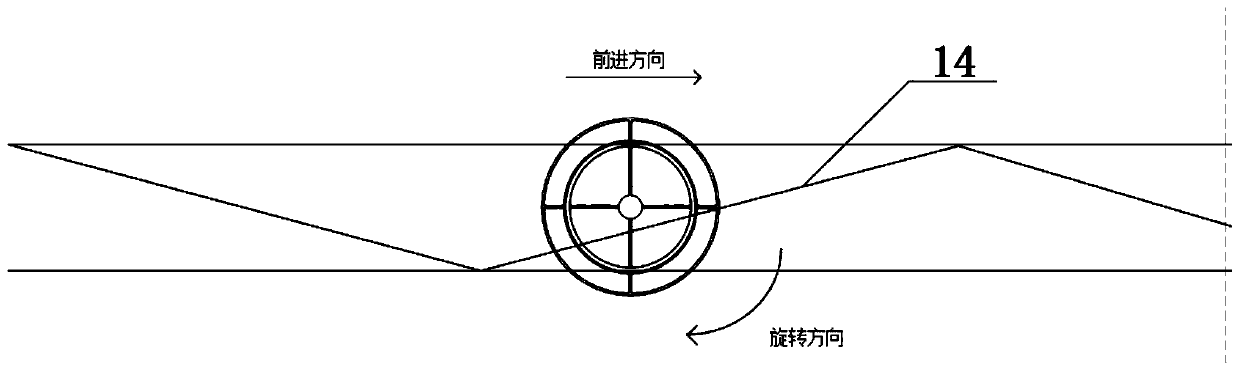

[0025] Figure 5 Shown is a ring-shaped skateboard pantograph for an electric traction locomotive. The shell 7 fixed on the roof of the locomotive is cylindrical, the inner wall of the shell 7 is fixed with a bearing 8, and the rotating shaft 4 is installed and fixed on the inner ring of the bearing 8. Above; the bracket 2 is formed by fixing the outer ends of a plurality of radial support arms by an annular support plate; the inner ends of the plurality of radial support arms of the bracket 2 are fixed on the top of the rotating shaft 4 protruding from the casing; used as a zigzag The contact line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com