Packing method of high-voltage cable coil and packing device thereof

A packaging method and high-voltage cable technology, applied in the field of high-voltage cable reel packaging method and its packaging equipment, can solve the problems of unsightly appearance, oversized packaging board, low work efficiency, etc., achieve accurate fixed position, realize automation, and save raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

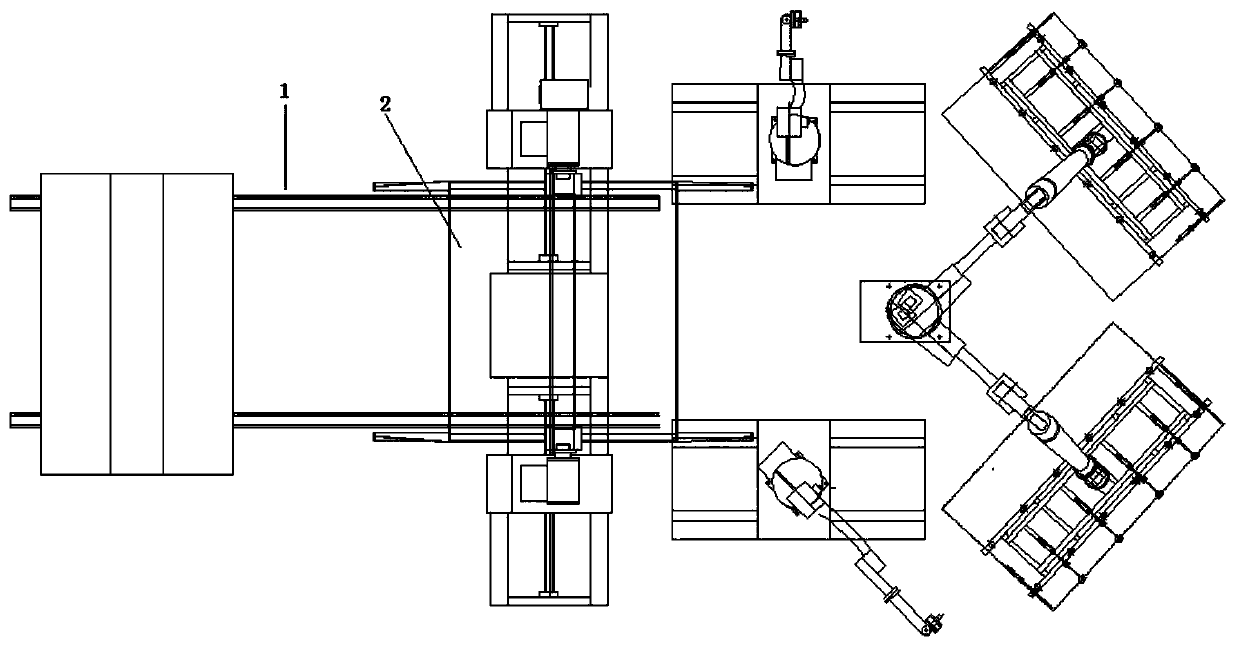

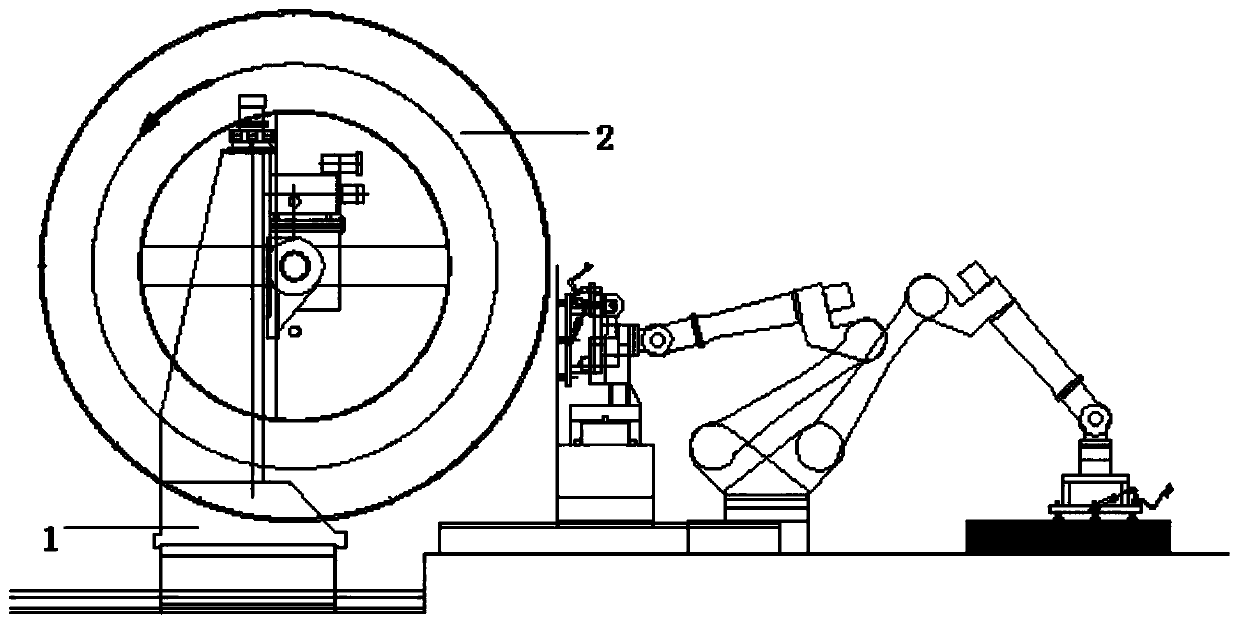

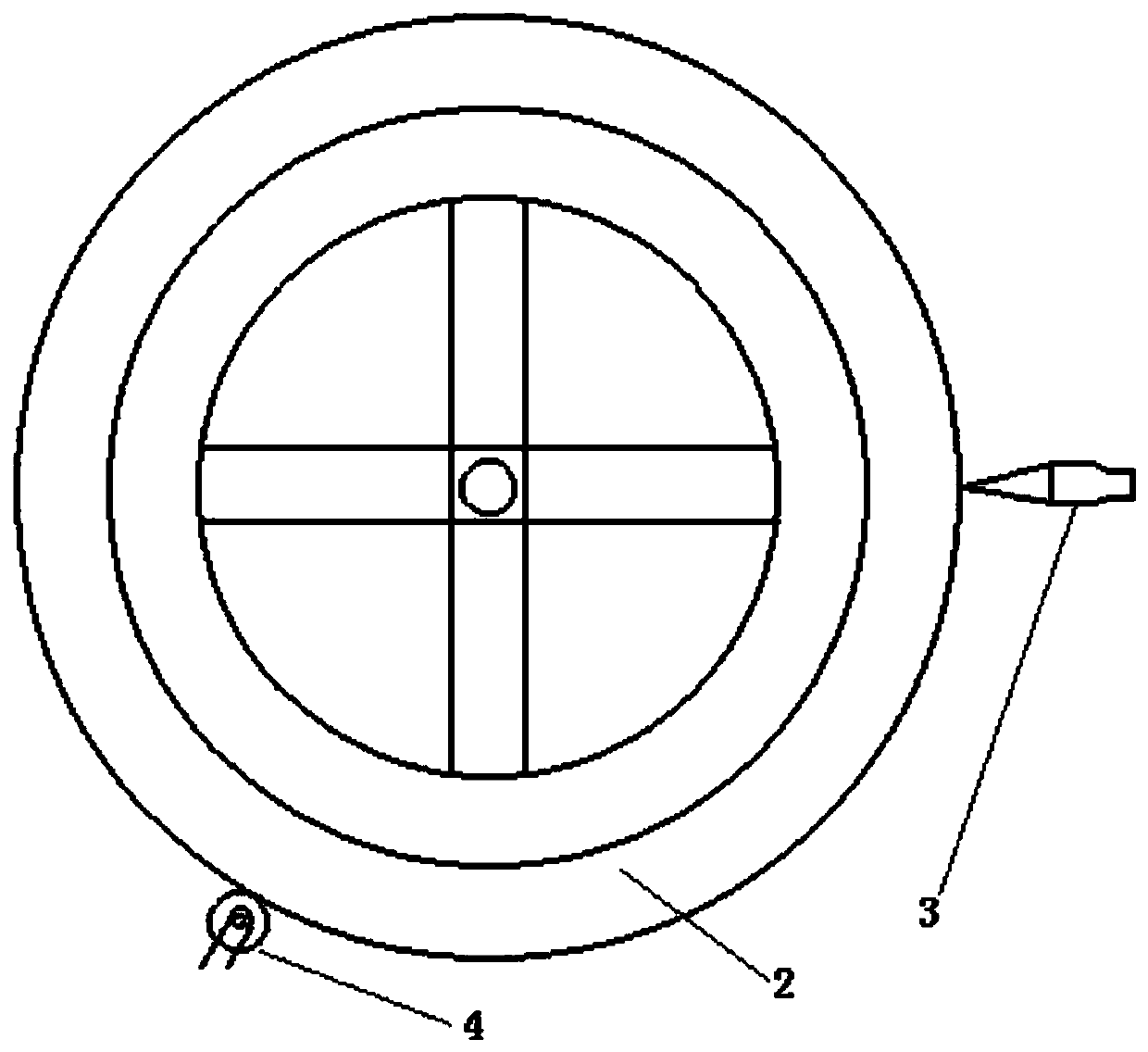

[0093] (1) Hoist the reel onto the reel by driving or carrying a trolley, then control the high-voltage cable reel to rotate at a constant speed on the transport trolley, and use the visual inspection device 3 to capture and determine the position of the first hole on the 2nd side of the high-voltage cable reel The first hole position coordinates, the control arc length detection device 4 records the first hole position as zero;

[0094] (2) Continue to control the high-voltage cable reel 2 to rotate at a constant speed according to the original direction through the drive mechanism on the side of the reel, control the visual detection device 3 to capture the second hole position on the side of the high-voltage cable reel 2 and determine the coordinates of the second hole position, and at the same time Control the arc length detection device 4 to record the arc length between the second hole position and the first hole position, and so on, the high-voltage cable reel 2 rotates ...

Embodiment 2

[0103](1) Control the rotation of the high-voltage cable reel on the transport trolley, capture and determine the coordinates of the first hole on the 2nd side of the high-voltage cable reel through the visual inspection device 3, and control the arc length detection device 4 to record the first hole position One hole position is zero position;

[0104] (2) Continue to control the rotation of the high-voltage cable reel 2 through the disk edge drive mechanism according to the original direction, control the visual detection device 3 to capture the second hole position on the side of the high-voltage cable reel 2 and determine the coordinates of the second hole position, and simultaneously control The arc length detection device 4 records the arc length between the second hole position and the first hole position, and so on, the high-voltage cable reel 2 rotates one revolution, and the visual detection device 3 is controlled to record the coordinates of each hole position, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com