High-shear-resistant brushing type thick slurry water-in-water coating material, preparation method and application thereof

A brushing and high-resistance technology, applied in coatings and other directions, can solve the problems of immature control of construction methods, affecting the use effect of products, and excessive release of harmful substances, achieving enhanced toughness, good storage stability, and stable later protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

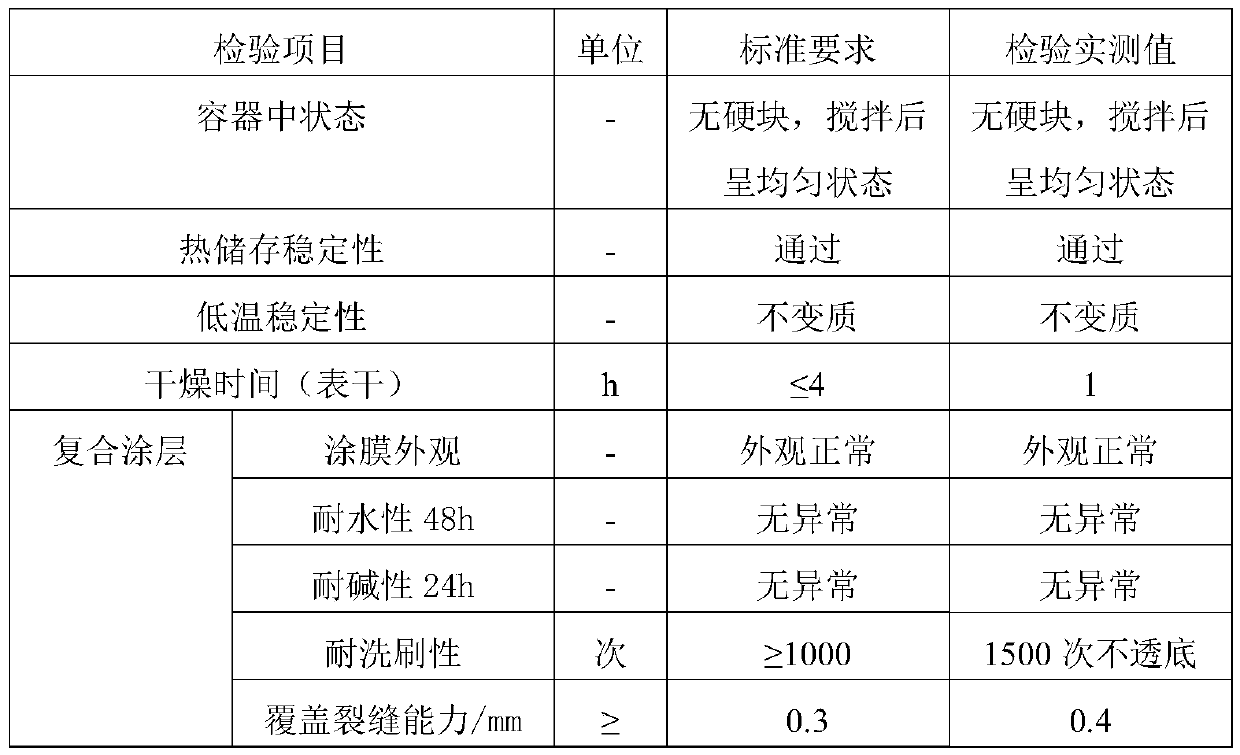

Examples

Embodiment 1

[0028] The purpose of this embodiment is to provide a high-shear-resistant brushing type thick build water-in-water coating, and the specific operation steps are as follows:

[0029] 1. Prepare colorful base paint: Mix 50kg water, 1kg hydroxyethyl cellulose, 0.1kg dispersant, 0.4kg defoamer, 0.1kg wetting agent, 4kg kaolin, 5kg heavy calcium and 0.5kg titanium dioxide and then disperse at high speed Evenly, add 2kg of coupling toughening agent to it, disperse at high speed for 20-30 minutes, then add 2kg of film-forming aid to it and continue to disperse for 5 minutes to make a slurry; add 25kg of emulsion to the above slurry, stir at low speed And add 0.1-0.3kg pH adjuster to make the pH value of the whole system reach 7-9, then add 0.1kg antiseptic and bactericide, mix well, and set aside;

[0030] 2. Prepare 5% cross-linking protection agent solution: add 5kg cross-linking protection agent to 95kg water, disperse at 1200-1500r / min for 20-40 minutes;

[0031] 3. Prepare the...

Embodiment 2

[0036] The purpose of this embodiment is to provide a high-shear-resistant brushing type thick build water-in-water coating, and the specific operation steps are as follows:

[0037] 1. Prepare colorful base paint: mix 50kg water, 1kg hydroxyethyl cellulose, 0.1kg dispersant, 0.4kg defoamer, 0.1kg wetting agent, 4kg kaolin, 5kg heavy calcium and 0.5kg titanium dioxide and then disperse at high speed Uniform, then add 2kg of coupling toughening agent to it, disperse at high speed for 20-30 minutes, then add 2kg of film-forming aid to it and continue to disperse for 5 minutes to make a slurry; add 25kg of emulsion to the above slurry, stir at low speed And add 0.1-0.3kg pH adjuster to make the pH value of the whole system reach 7-9, then add 0.1kg antiseptic and bactericide, mix well, and set aside;

[0038] 2. Prepare 10% crosslinking protection agent solution: add 10kg crosslinking protection agent to 90kg water and disperse for 20-40 minutes at 1200-1500r / min;

[0039] 3. Pr...

Embodiment 3

[0044] The purpose of this embodiment is to provide a high-shear-resistant brushing type thick build water-in-water coating, and the specific operation steps are as follows:

[0045] 1. Prepare colorful base paint: mix 50kg water, 1kg hydroxyethyl cellulose, 0.1kg dispersant, 0.4kg defoamer, 0.1kg wetting agent, 4kg kaolin, 5kg heavy calcium and 0.5kg titanium dioxide and then disperse at high speed Uniform, then add 2kg of coupling toughening agent to it, disperse at high speed for 20-30 minutes, then add 2kg of film-forming aid to it and continue to disperse for 5 minutes to make a slurry; add 25kg of emulsion to the above slurry, stir at low speed And add 0.1-0.3kg pH adjuster to make the pH value of the whole system reach 7-9, then add 0.1kg antiseptic and bactericide, mix well, and set aside;

[0046] 2. Prepare 7% cross-linking protection agent solution: add 7kg cross-linking protection agent to 93kg water and disperse for 20-40 minutes at 1200-1500r / min;

[0047] 3. Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com