Cheese low-temperature pretreatment process

A pre-treatment and cheese yarn technology, applied in liquid/gas/vapor yarn/filament processing, textile material processing, liquid/gas/vapor processing of textile materials of a certain length, etc., which can solve the problem of yarn moisture absorption or wetting. Poor adhesion, poor adhesion between yarns and dyes, and detachment of dyed yarns, etc., to improve adhesion, improve cleanliness, and reduce the degree of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

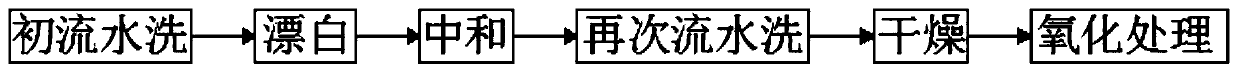

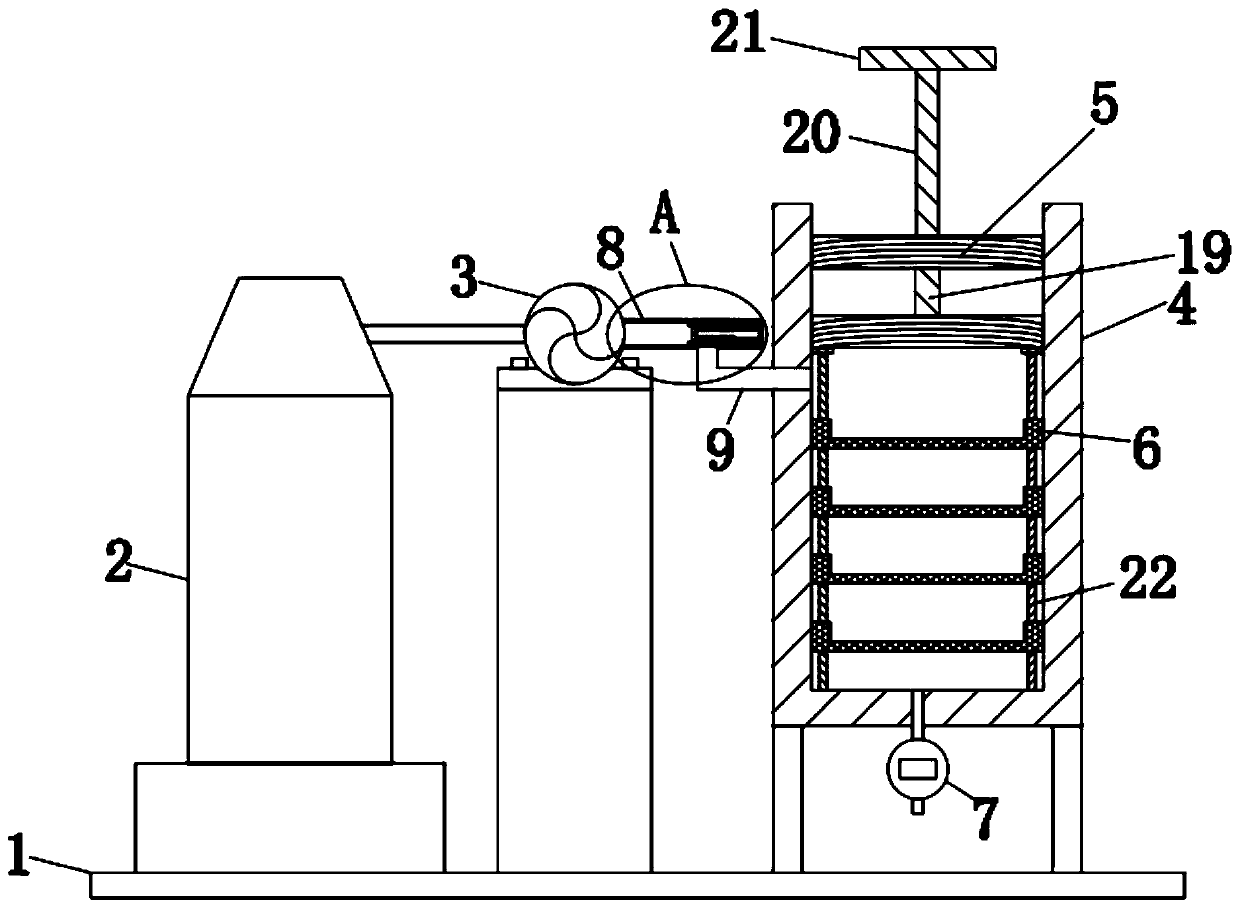

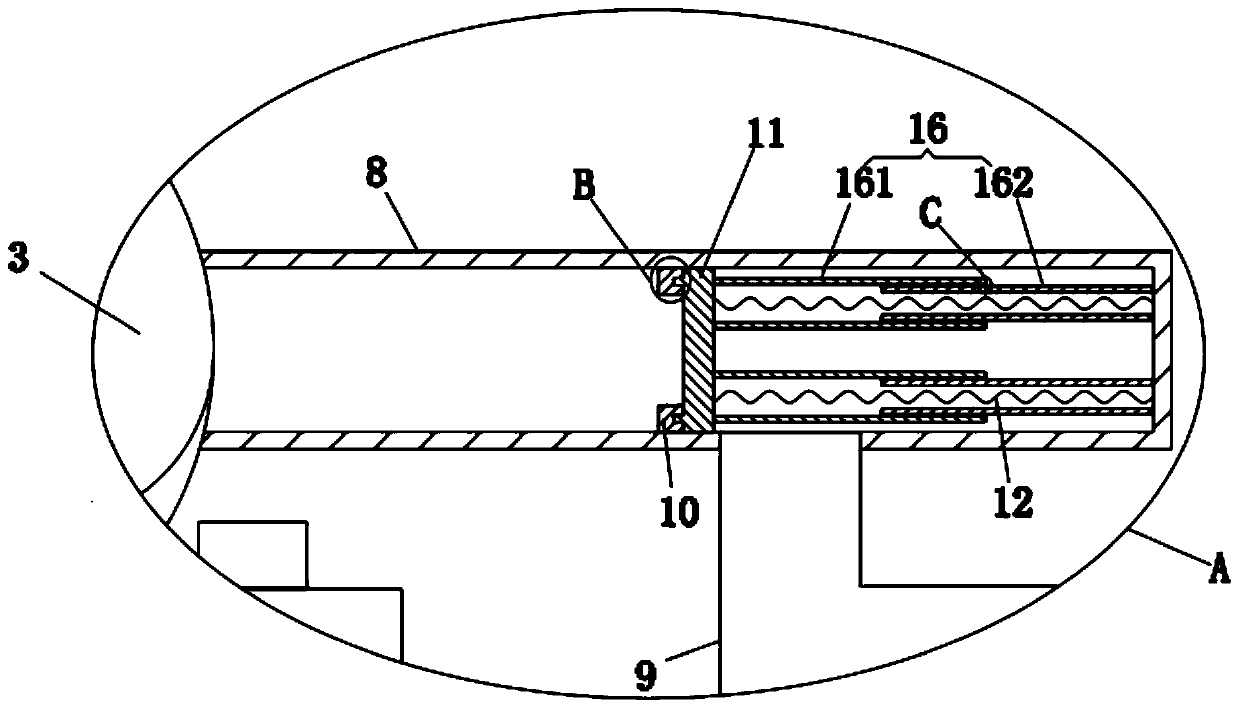

[0037] Such as figure 1 As shown, a cheese low temperature pretreatment process specifically comprises the following steps:

[0038] S1: Washing in the initial flow: first wash the yarn with running water;

[0039] S2: Bleaching: Add sodium borate into the bleaching tank, put the yarn into the bleaching tank for bleaching;

[0040] S3: Neutralization: neutralize the bleached yarn inside the neutralization pool that puts the acidic solution into it;

[0041] S4: washing with running water again: washing the neutralized yarn with running water;

[0042] S5: drying: drying by pressing rollers and dryers;

[0043] S6: Oxidation treatment: Control the pressure inside the oxidation device to 60-80Pa, and then perform low-temperature oxidation treatment on the yarn through the oxidation device.

[0044] Further, in S1 and S4, the water temperature is controlled at 60-70 degrees Celsius.

[0045] Further, in S2, control the concentration of sodium borate in the bleaching tank at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com