Cooling system for realizing high-precision temperature control and control method of cooling system

A cooling system, high-precision technology, applied in the field of cooling systems, can solve problems such as cooling system steps, water temperature fluctuations, energy waste, etc., to achieve the effects of avoiding energy waste, ensuring stability, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

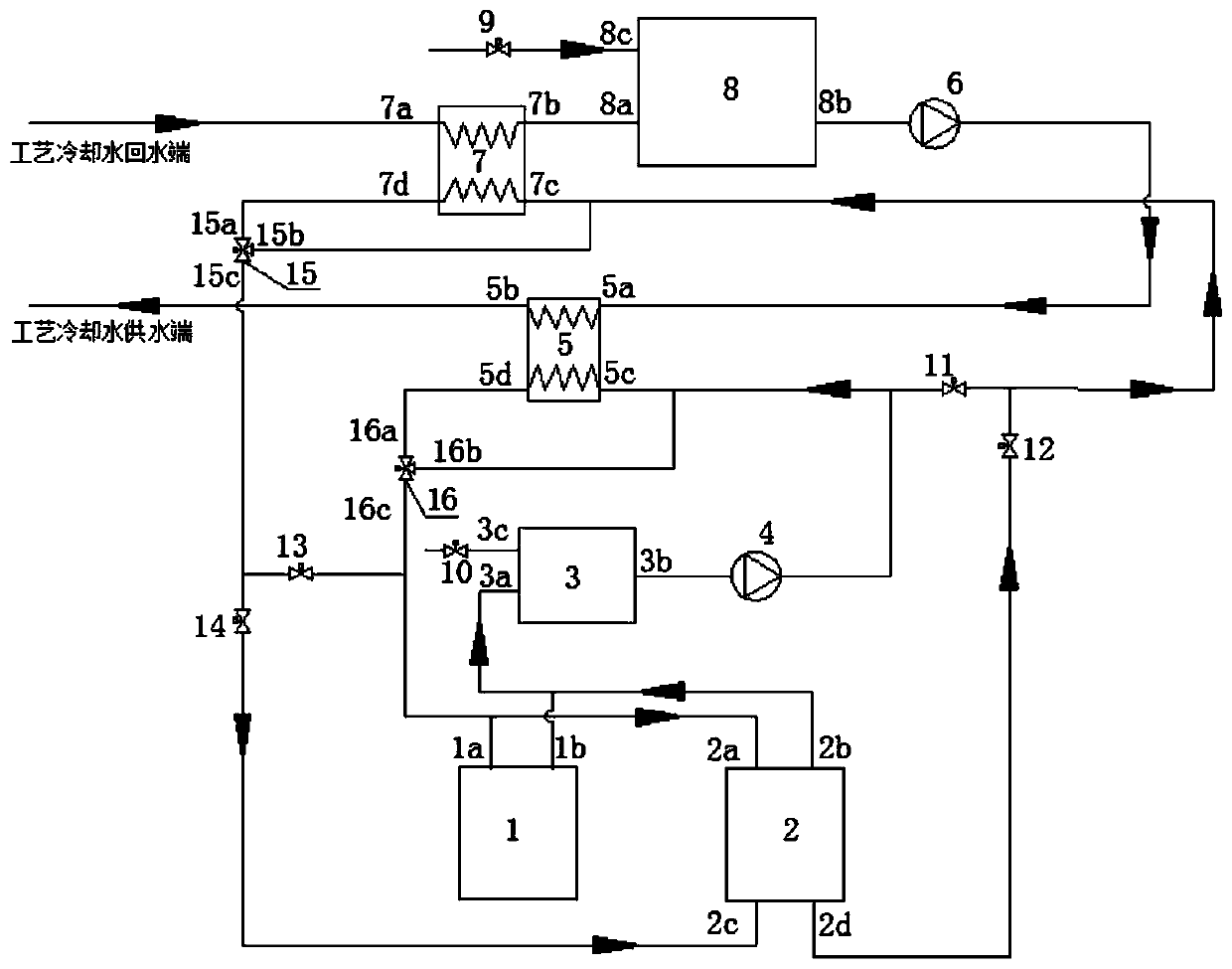

[0021] In the present invention, the plate heat exchanger for cooling and the plate heat exchanger for temperature control in the conventional mode chilled water circuit are connected in parallel, so as to realize the separate regulation and control of the cooling water temperature and the temperature control of the process cooling water. The chilled water from the first outlet of the first refrigerator enters the buffer water tank and the chilled water pump in turn. The chilled water at the chilled water pump outlet is divided into two paths, one enters the plate heat exchanger for temperature control, and the other passes through the third solenoid valve into the plate type for cooling. The second input end of the heat exchanger flows out from the second output end, and is mixed with the chilled water at the second output end of the plate heat exchanger for temperature control through the fifth solenoid valve, and enters the first water return port of the air conditioner refrig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com