Cylindrical battery thermal parameter quasi-steady-state measuring method and device

A cylindrical battery and measurement method technology, applied in the direction of material thermal development, etc., can solve the problems such as the inability to directly measure the radial thermal conductivity and specific heat of the cylindrical battery, the lack of direct measurement of battery thermal parameters, and the difficulty in ensuring the measurement accuracy. Fast, direct and fast measurement, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

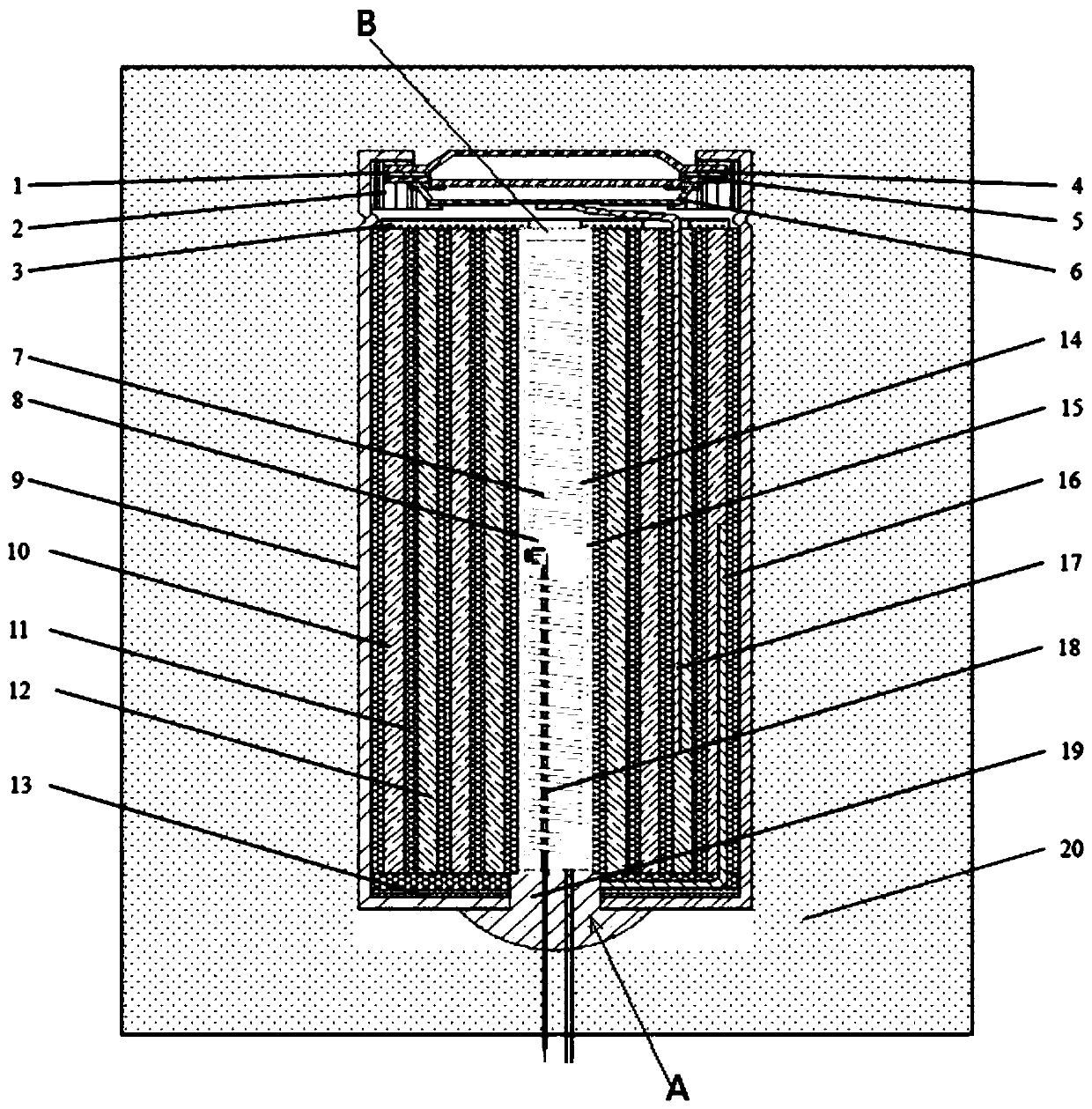

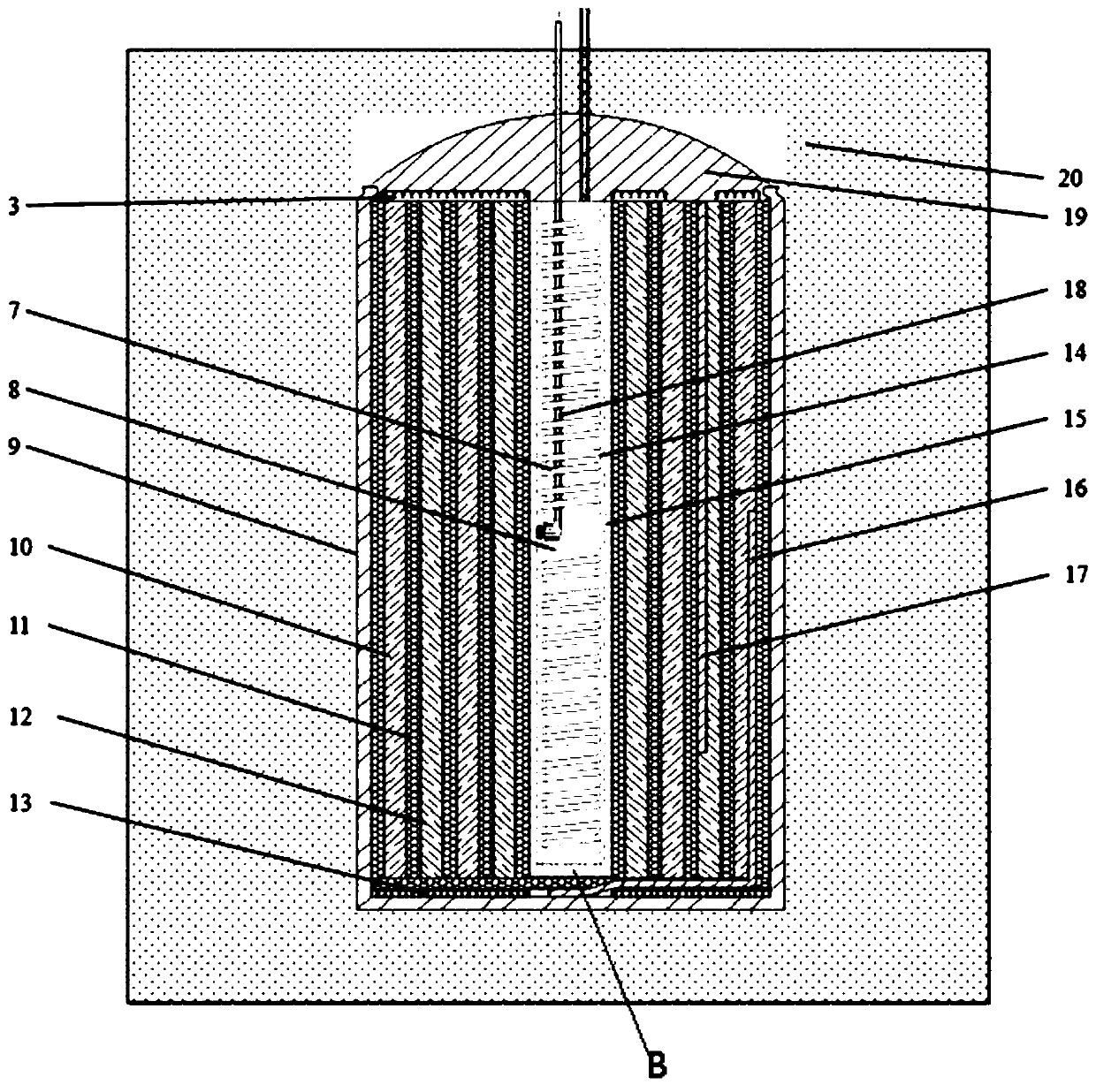

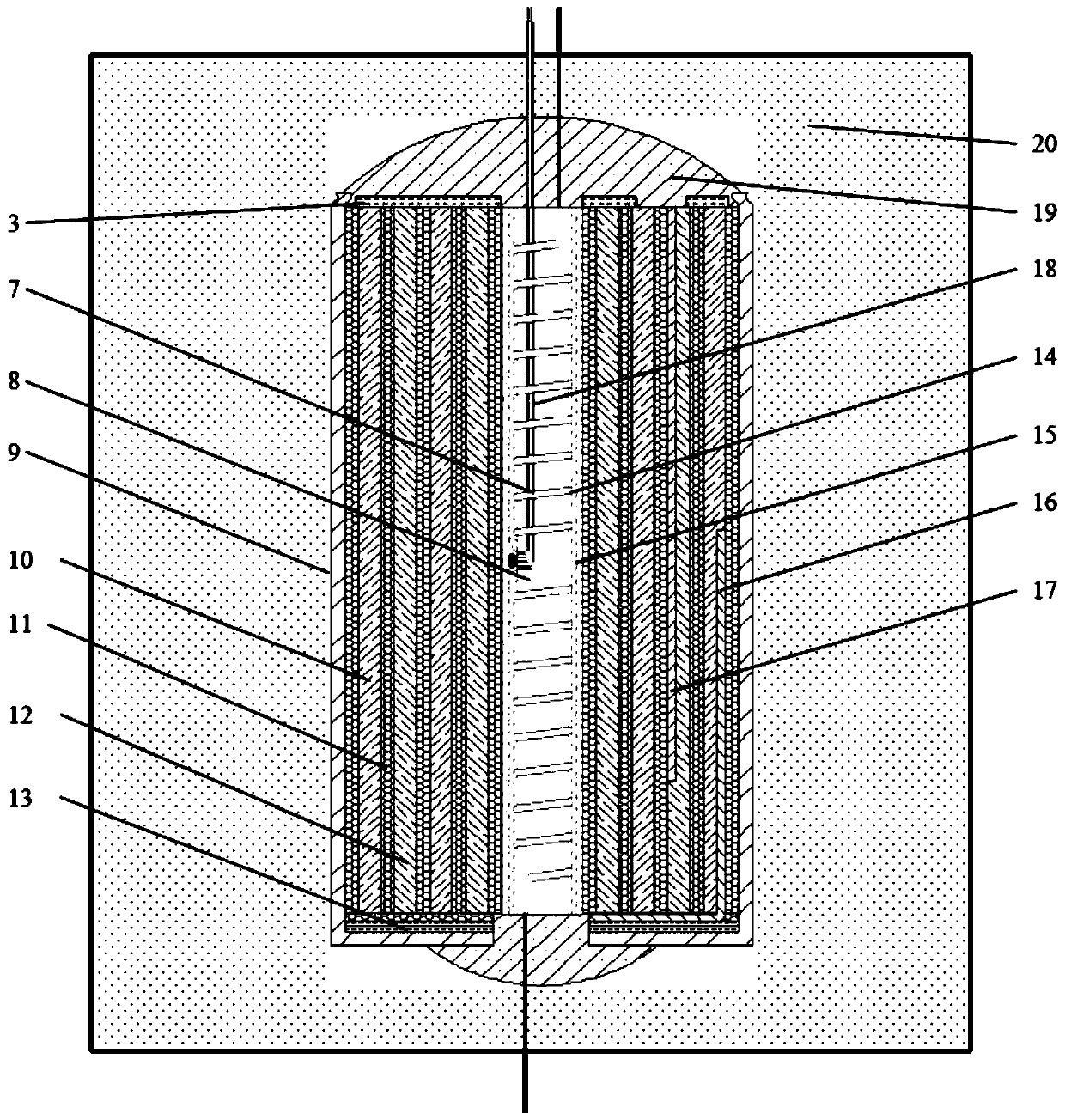

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. According to the following description, the purpose, technical solution and advantages of the present invention will be more clear. It should be noted that the described embodiments are preferred embodiments of the present invention, but not all embodiments.

[0047] In this embodiment, a commonly used Panasonic 18650 cylindrical battery is used. The positive and negative electrodes are lithium cobaltate and graphite, respectively, with a diameter of 18.2mm and a length of 65mm.

[0048] combine Figure 1 to Figure 4 Shown, a cylindrical battery thermal parameter quasi-steady-state determination method, comprising the following steps:

[0049] S1. Discharge the cylindrical battery 24 to be tested to the cut-off voltage, that is, the state of charge is 0, and then cut the positive end cap at the neck of the positive end cap to remove t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com