Integrated battery charging and discharging equipment

A charging and discharging equipment, charging and discharging technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of crossing and misalignment of charging and discharging cables, low overall efficiency of equipment, high energy loss, etc., to avoid wiring errors, Reduce electricity costs and reduce space occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

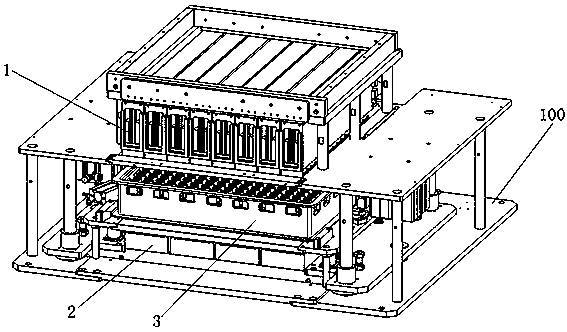

[0034] A kind of integrated battery charging and discharging equipment of this embodiment, its overall structural diagram sees figure 1 As shown, it includes a machine tool 100 , and a positive electrode module 1 and a negative electrode module 2 arranged on the machine tool 100 . The positive module 1 and the negative module 2 correspond to each other, and the positive module 1 and the negative module 2 are arranged on the worktable of the machine tool 100 through guide columns, and can be closed or separated from each other. Between the positive electrode module 1 and the negative electrode module 2 is a three-dimensional station for battery charge and discharge testing. Temperature and smoke detectors can be installed in the test station to sense fire safety hazards. Moreover, in some embodiments, the negative module 2 and the positive module 1 can be highly integrated, that is, the negative module 2 is integrated on the positive module 1. At this time, between the positive...

Embodiment 2

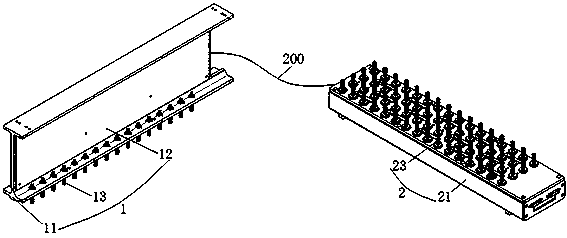

[0046] This embodiment is the same as Embodiment 1, the difference is that, see Figure 4 As shown, the common power supply PCB of the positive power supply part 12 and the negative power supply part 22 is fixedly installed on the positive pole module support body 11, and one end of the chuck of the positive pole clamp part 13 of the positive pole module 1 is in contact with the positive pole of the power supply PCB. .

[0047] And, specifically, the negative electrode module support member 21 is a housing, one end of the chuck of the negative electrode clamp part 23 is installed on the negative electrode module support part 21, and the other end extends out of the negative electrode module support part 21, and the negative electrode clamp part 23 The collet is connected to the negative interface of the common power supply PCB on the positive module 1 through the connection line 200 . Therefore, the integrated arrangement of the power supply part and the mechanical fixture pa...

Embodiment 3

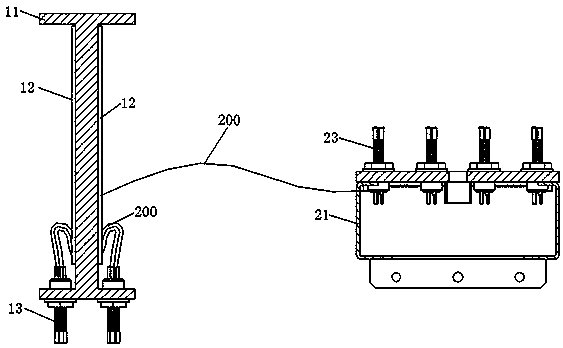

[0049] This embodiment is the same as Embodiment 1, the common power supply PCB of the positive power supply part 12 and the negative power supply part 22 is fixedly installed on the positive pole module support body 11, the difference is that, see Figure 5 As shown, on the positive electrode module 1 , the collet of the positive electrode fixture part 13 is fixedly installed on the positive electrode module support body 11 , and the positive interface of the common power supply PCB is connected and installed on the collet of the positive electrode fixture part 13 .

[0050] And, specifically, the negative electrode module support member 21 is a housing, one end of the chuck of the negative electrode clamp part 23 is installed on the negative electrode module support part 21, and the other end extends out of the negative electrode module support part 21, and the negative electrode clamp part 23 The chuck of the clamp is connected to the negative pole of the common power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com