automobile windshield forming simulation method based on COMSOL Multiphysics

A simulation method, the technology of automotive glass, is applied in the field of molding simulation, which can solve the problems of incomplete molding, high dependence on engineer experience, long production cycle, etc., and achieve the effect of simple and convenient operation, reducing experiment time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0037] The present invention provides a COMSOL Multiphysics-based GT molding simulation method for automotive glass, comprising the following steps:

[0038] Step S1: build a simplified heating furnace model and a flat glass original sheet model;

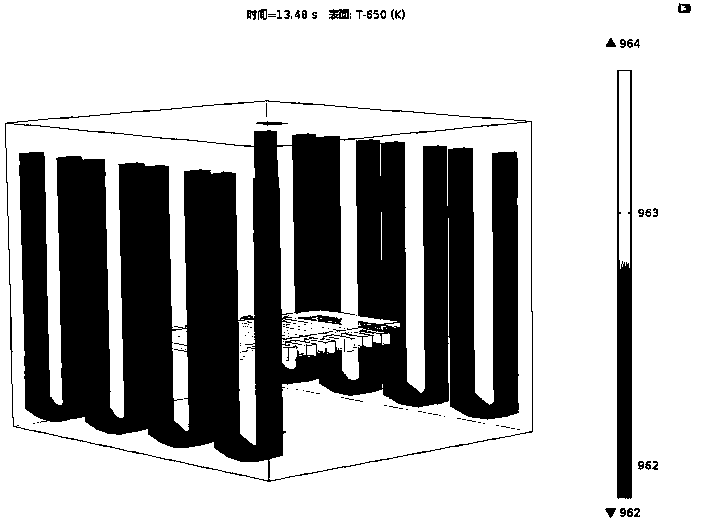

[0039] Step S2: According to the heating furnace model obtained and the flat glass original sheet model, the temperature field and the stress field are simulated by COMSOL Multiphysics software to simulate the glass heating and softening process;

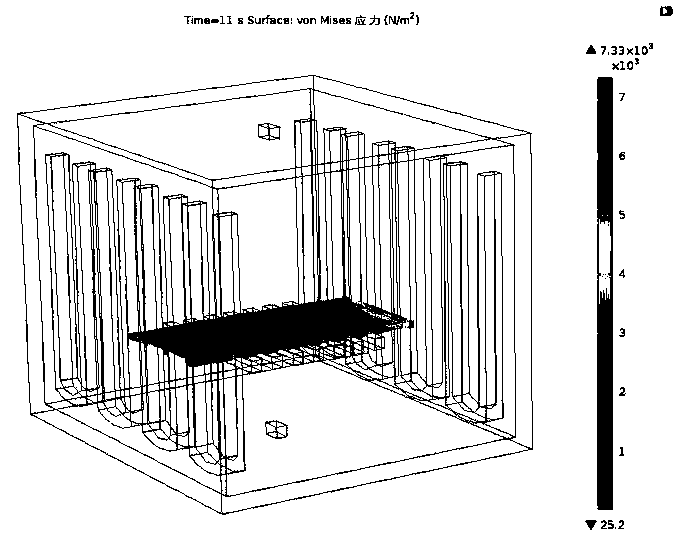

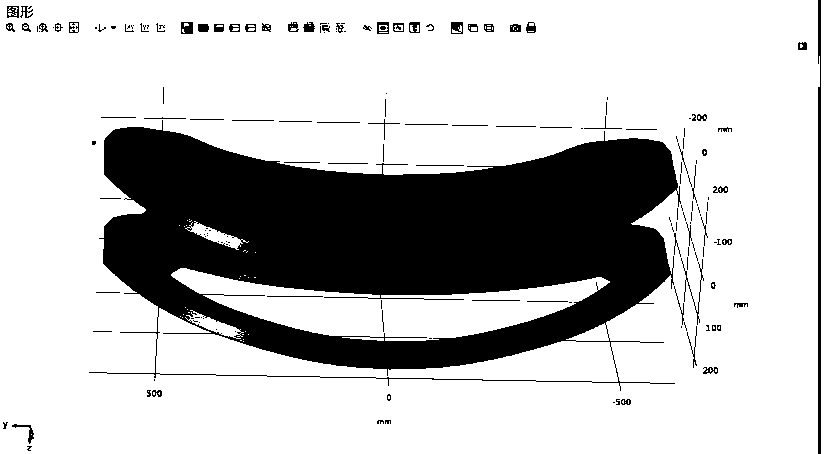

[0040] Step S3: Construct the male mold, the thermoforming ring and the flat glass geometric physical model, and simulate the stress field and temperature field through the COMSOLMultiphysics software to simulate the hot bending forming stage;

[0041] Step S4: After the hot pressing is completed, build a cold ring, and use COMSOL Multiphysics to simulate the glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com