Intelligent platform for live operation inspection of transformer substation

A substation and platform technology, applied in the power grid field, can solve the problems of reduced cable insulation, inconvenient operation and maintenance personnel, signal errors, etc., to ensure safety, achieve complete real-time acquisition, and real-time effective and accurate acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

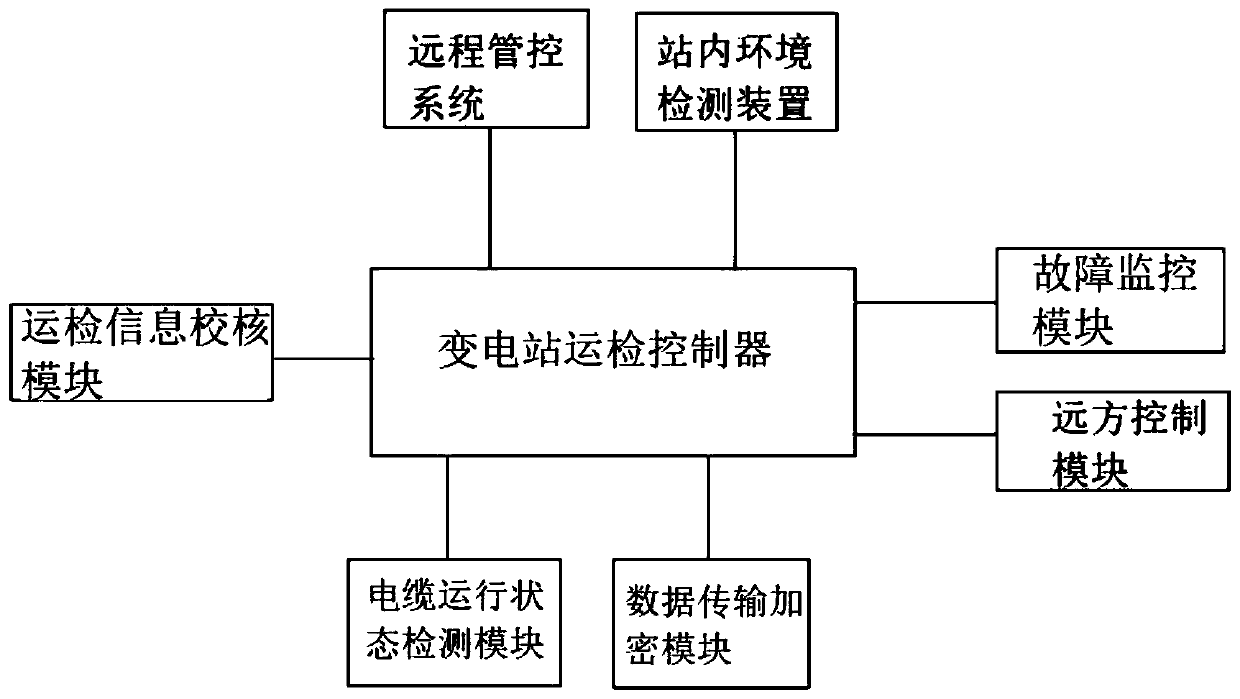

[0050] An intelligent platform for live inspection of substations disclosed in one or more embodiments, such as figure 1 As shown, it includes: the substation operation inspection controller, which communicates with the remote control system, the station environment detection device, the remote control module, the fault monitoring module and the cable operation status detection device respectively through the communication cable;

[0051] This embodiment designs a cable structure, including: a protective layer, a buffer layer, an armor layer, an aluminum foil layer, an insulating layer, and a conductive core arranged sequentially from outside to inside; several buffer units are uniformly arranged on the buffer layer, The buffer unit is a hollow structure arranged along the direction of the cable; the conductive core includes a copper wire and an aluminum wire, and the copper wire and the aluminum wire are twisted to form a conductive core.

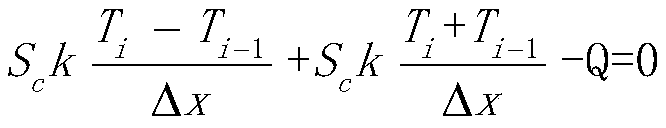

[0052] Among them, the processing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com