Electromagnetic pulse welding system special for PCB welding

An electromagnetic pulse, PCB board technology, used in welding equipment, electric heating devices, printed circuits, etc., can solve problems such as soldering off, device performance degradation, and increased contact resistance, to ensure cleanliness and reduce welding steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

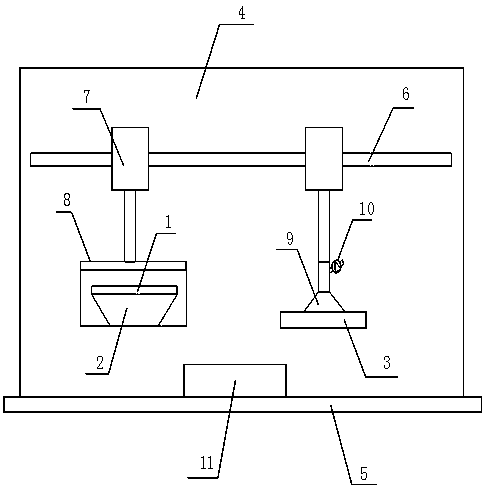

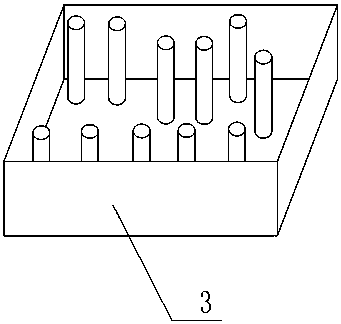

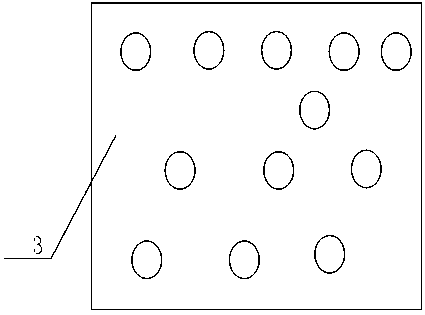

[0024] An electromagnetic pulse welding system specially used for PCB board welding, including a bearing base 5, an electromagnetic pulse welding assembly, and a shielding mold 3. This embodiment defines the PCB board to be welded, that is, the back side of the printed circuit board 12 is provided with a number of solder joints 14 arranged in an array and holes passing through the electronic components, and the electronic components pass through the holes, and the pins of the electronic components 13 is bent to correspond to the solder joint 14 on the back of the printed circuit board 12 , and has a certain distance from the solder joint 14 . Such a PCB board to be soldered is placed on the carrying base 5 with its back facing upwards.

[0025] The electromagnetic pulse welding assembly includes a pulse power supply, a coil 1 and a flat magnet collector 2, and the coil 1 is located above the flat magnet collector 2 and connected to the pulse power supply.

[0026] Specificall...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that a limiting frame or a limiting seat 11 is provided on the bearing base 5, and the boundary of the PCB board can be placed on the limiting frame for support.

[0032] The limit seat 11 is a boss and is provided with a plurality of placement grooves matching the size and position of the electronic components on the PCB board to be soldered.

Embodiment 3

[0034] The difference between this embodiment and Embodiment 1 is that other designs are made to improve the mechanization of the system.

[0035] In this embodiment, the mounting frame 8 is made of non-conductive material, and the mounting frame 8 is an inverted L-shaped structure, and the coil 1 and the flat magnetic collector 2 are bonded to the mounting frame 8 by an adhesive. The supporting base 5 is provided with a support plate 4, and the top of the installation frame 8 is set on the support plate 4 through the electric push rod 7, so that the flat magnetic collector 2 can move up and down, which is convenient for placing and taking out the PCB board.

[0036] Further, the electric push rod 7 is connected with the support plate 4 through the slider, and the support plate 4 is provided with a horizontally arranged electric slide rail 6 for the slider to slide, so that the electromagnetic pulse assembly can move left and right and up and down on the support plate 4 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com