Crystalline glaze and preparation method thereof

A technology of crystalline glaze and glaze paste, applied in the field of ceramic glaze, can solve the problems of inconsistent shape and size of crystal flowers, inability to mass-produce, product bursting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

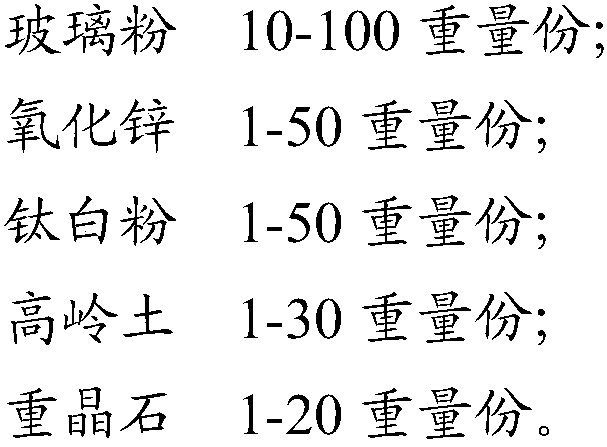

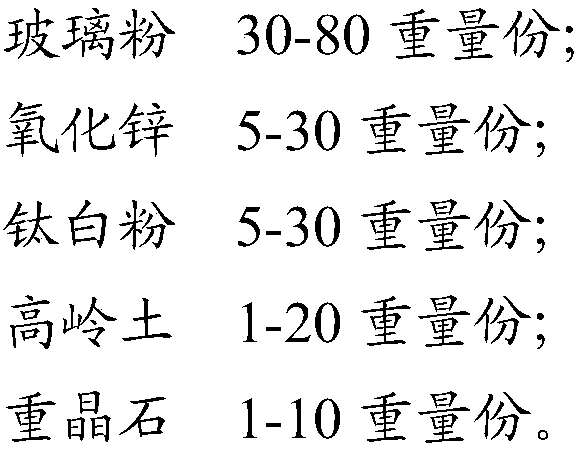

[0057] The present invention also provides the preparation method of above-mentioned crystalline glaze, comprises the following steps:

[0058] 1) taking glass powder, zinc oxide, titanium dioxide, and kaolin by weight as raw materials, adding water to grind the glaze slurry;

[0059] 2) Add barite in parts by weight and mix well;

[0060] 3) Apply glaze to the body and fire it.

[0061] Preferably, ball milling is used to grind the glaze slurry. In step 1), the ratio of the raw materials, balls and water is 1:2-5:0.5-2.

[0062] Preferably, in step 2), after barite is added, the concentration of the glaze slurry is 35-50 degrees Baume.

[0063] Preferably, in step 3), the firing process is carried out under an oxidizing atmosphere, the firing temperature is 1200-1300° C., and the firing time is 6-10 hours.

[0064] The present invention also provides a preparation method of the above-mentioned crystalline glaze. Firstly, each raw material except barite is weighed by weight...

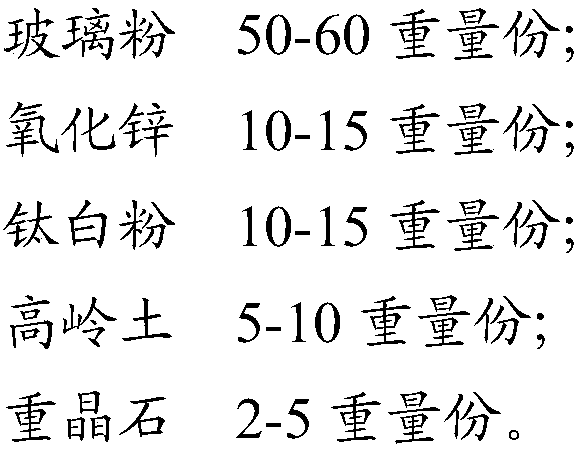

Embodiment 1

[0067] 50 parts by weight of glass powder ground by medical colorless glass

[0068] Zinc oxide 10 parts by weight

[0069] Titanium dioxide 10 parts by weight

[0070] Kaolin 5 parts by weight

[0071] Barite 2 parts by weight.

[0072] Preparation:

[0073] 1) Weigh glass powder, zinc oxide, titanium dioxide, and kaolin as raw materials according to the above parts by weight, add water, and use ball milling to grind glaze slurry. The ratio of raw materials, balls, and water is 1:2:0.8;

[0074] 2) Add barite crushed to 60 mesh according to the above weight parts, mix well, and the concentration of the prepared glaze slurry is 35 degrees Baume;

[0075] 3) Glaze is applied to the green body by dipping, and fired in an oxidizing atmosphere at a firing temperature of 1280°C and a firing time of 8 hours.

Embodiment 2

[0077] 55 parts by weight of glass powder

[0078] Zinc oxide 13 parts by weight

[0079] Titanium dioxide 13 parts by weight

[0080] Kaolin 8 parts by weight

[0081] Barite 5 parts by weight.

[0082] Preparation:

[0083] 1) Weigh glass powder, zinc oxide, titanium dioxide, and kaolin as raw materials according to the above parts by weight, add water, and use ball milling to grind glaze slurry. The ratio of raw materials, balls, and water is 1:2:0.8;

[0084] 2) Add barite crushed to 80 mesh according to the above parts by weight, mix well, and the concentration of the prepared glaze slurry is 40 degrees Baume;

[0085] 3) Glaze is applied to the green body in the way of pouring glaze, and fired in an oxidizing atmosphere with a firing temperature of 1260°C and a firing time of 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com