Extraction method of abelmoschus esculentus pectin

An extraction method and okra technology, applied in the field of okra pectin extraction, can solve the problems of immature process and high cost, and achieve the effects of low cost, quality improvement and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

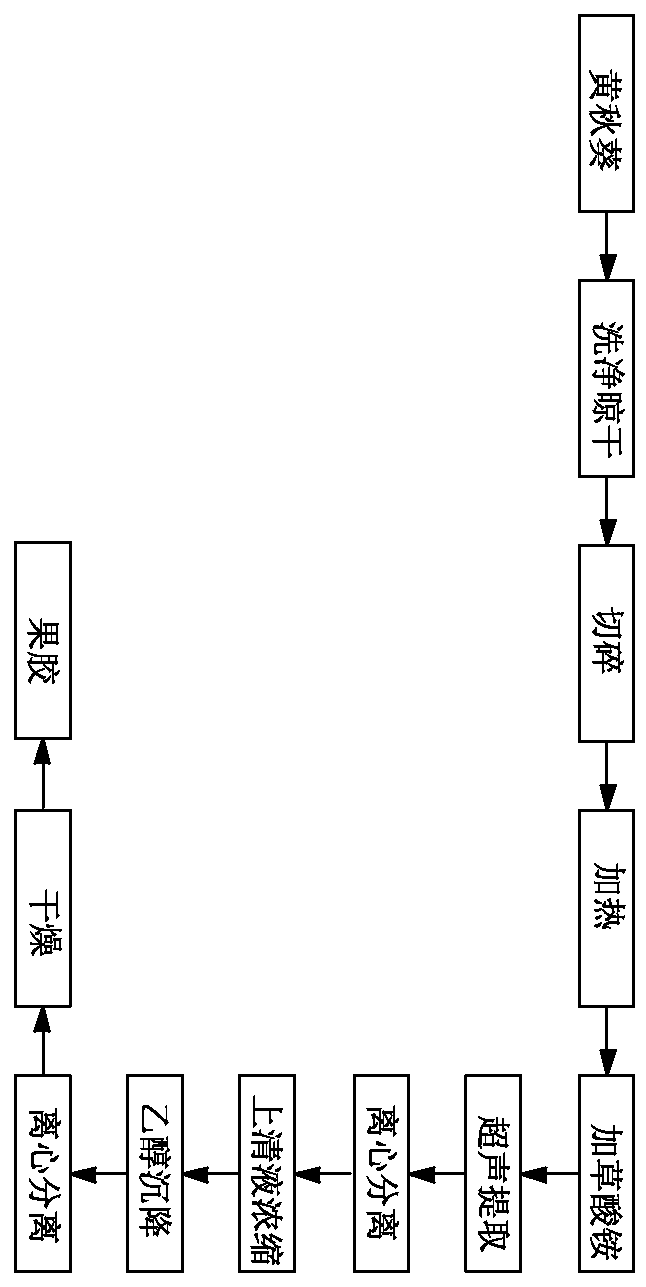

[0013] Below in conjunction with accompanying drawing, the present invention is further described:

[0014] Such as figure 1 A method for extracting okra pectin includes the following steps: (1), okra is washed and dried, then chopped to obtain pieces; (2), adding distilled water to the pieces and heating to boiling; (3 ), ammonium oxalate was added to the boiling liquid and stirred until dissolved; (4), the boiling liquid was ultrasonically extracted to obtain an extract; (5), the extract was centrifuged to obtain a supernatant; (6), the After the above supernatant is concentrated, ethanol is added to settle; (7), the centrifuged solid obtained after the settled liquid is centrifuged is dried to obtain pectin; the boiling time lasts 30 minutes; the solidification of the okra and distilled water The liquid ratio is 1:10; the temperature of the ultrasonic extraction is 80°C; the concentration of the ethanol is 95%; the concentration temperature is 60°C; the concentration of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com