Ethanol gasoline detergent and production method thereof

A technology of ethanol gasoline and its manufacturing method, which is applied in the field of fuel additives, can solve the problems of prolonging engine life, reducing consumption, and high added value, and achieves the effects of improving lubricating performance, reducing consumption, and making driving easier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

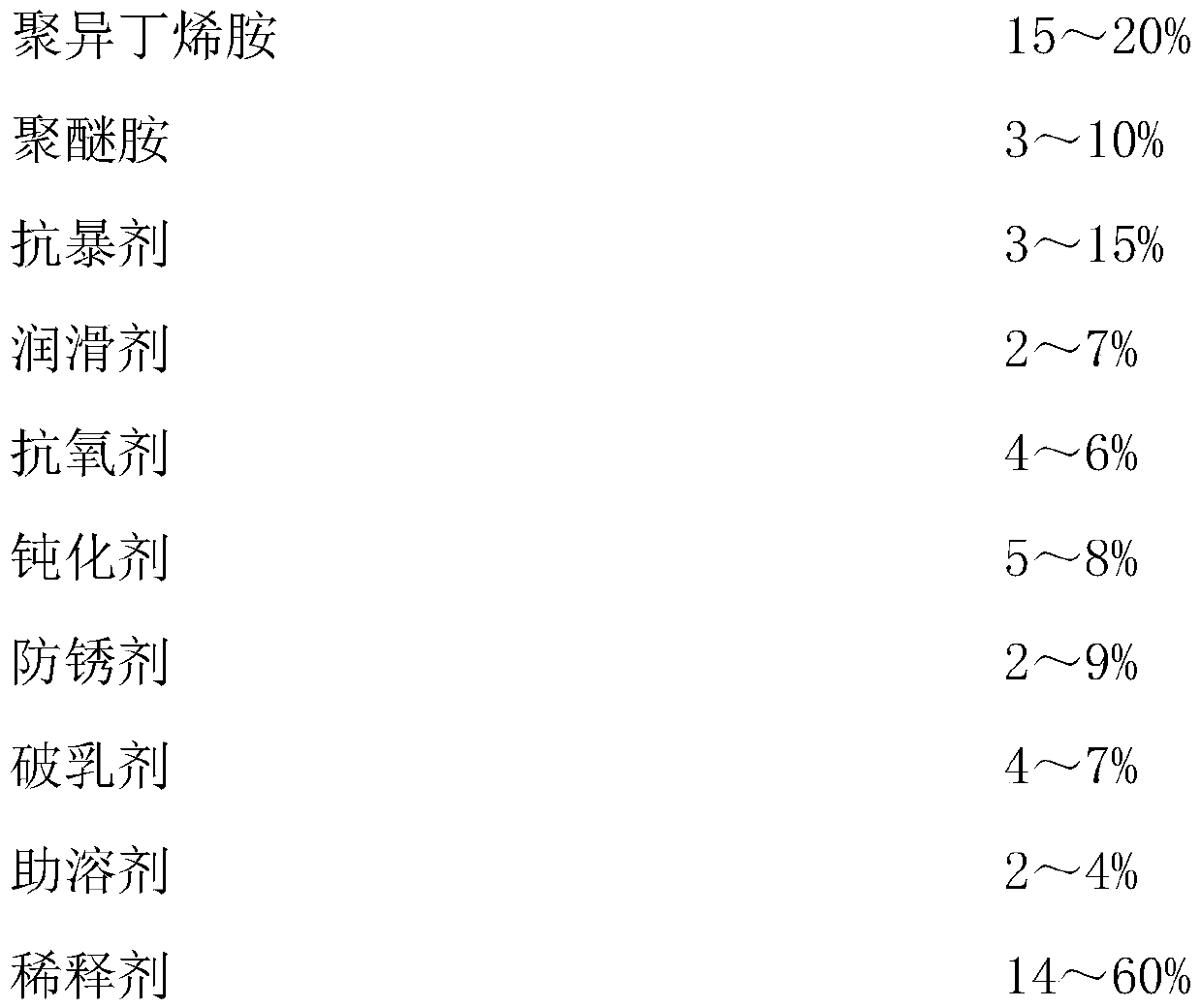

[0033] A kind of ethanol gasoline cleaning agent, its component and mass parts thereof are as follows:

[0034]

Embodiment 2

[0036] The manufacture method of ethanol gasoline cleaning agent is characterized in that comprising the following steps:

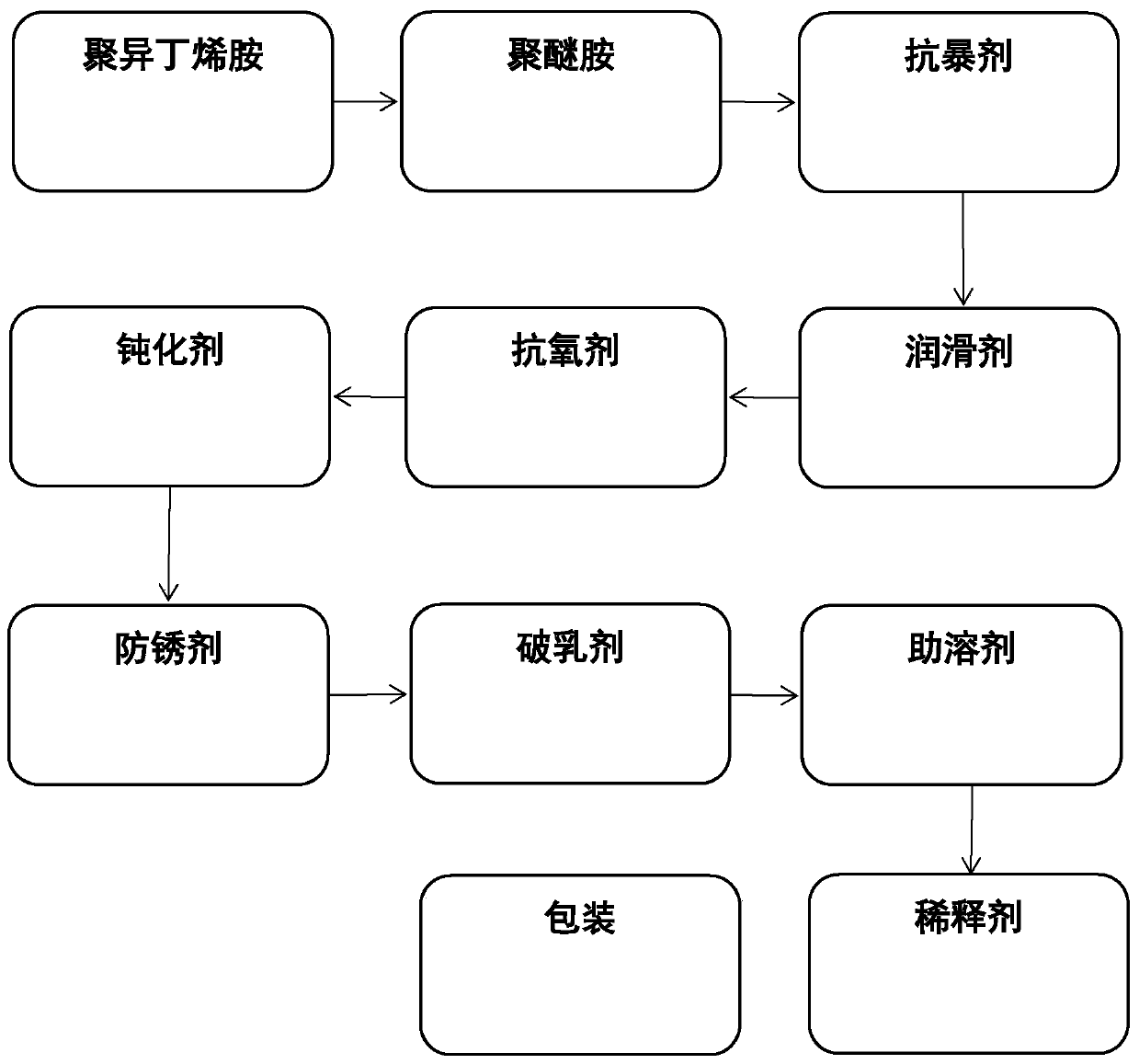

[0037] Step 1: mixing polyisobutylene amine and polyether amine to obtain a primary mixture product;

[0038] Step 2: adding anti-riot agent, lubricant and antioxidant to the mixed product to obtain a secondary mixture;

[0039] Step 3: adding passivating agent, antirust agent and demulsifier to the secondary mixture to obtain the tertiary mixture;

[0040] Step 4: Finally, add co-solvent and diluent to obtain the target product;

[0041] Prepare 1 ton (1000Kg) of the product of the present invention.

[0042] Preparation steps: 150kg of polyisobutylamine, 30kg of polyetheramine, 30kg of anti-riot agent, 20kg of lubricant, 40kg of antioxidant, 50kg of passivator, 20kg of rust inhibitor, 40kg of demulsifier, 20kg of cosolvent, and 600kg of diluent.

[0043] After mixing, the target product is obtained: ethanol gasoline detergent. Put the ethanol gasoli...

Embodiment 3

[0045] The manufacture method of ethanol gasoline cleaning agent is characterized in that comprising the following steps:

[0046] Step 1: mixing polyisobutylene amine and polyether amine to obtain a primary mixture product;

[0047] Step 2: adding anti-riot agent, lubricant and antioxidant to the mixed product to obtain a secondary mixture;

[0048] Step 3: adding passivating agent, antirust agent and demulsifier to the secondary mixture to obtain the tertiary mixture;

[0049] Step 4: Finally, add co-solvent and diluent to obtain the target product;

[0050] Prepare 1 ton (1000Kg) of the product of the present invention.

[0051] Preparation steps: 200kg of polyisobutylamine, 100kg of polyetheramine, 150kg of anti-riot agent, 70kg of lubricant, 60kg of antioxidant, 80kg of passivator, 90kg of rust inhibitor, 70kg of demulsifier, 40kg of cosolvent, and 140kg of diluent.

[0052] The target product is prepared according to the method in the claims. Use the same car to driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com