Method for preparing micro-pit structure and super-hydrophobic metal surface in large area on net mask

A metal surface and micro-pit technology, which is applied to the preparation of large-area micro-pit structures on metal surfaces and the preparation of super-hydrophobic surfaces, can solve the problem of gas film being difficult to maintain for a long time, and achieve a wide range of process applications and low cost. Low, the effect of mature preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

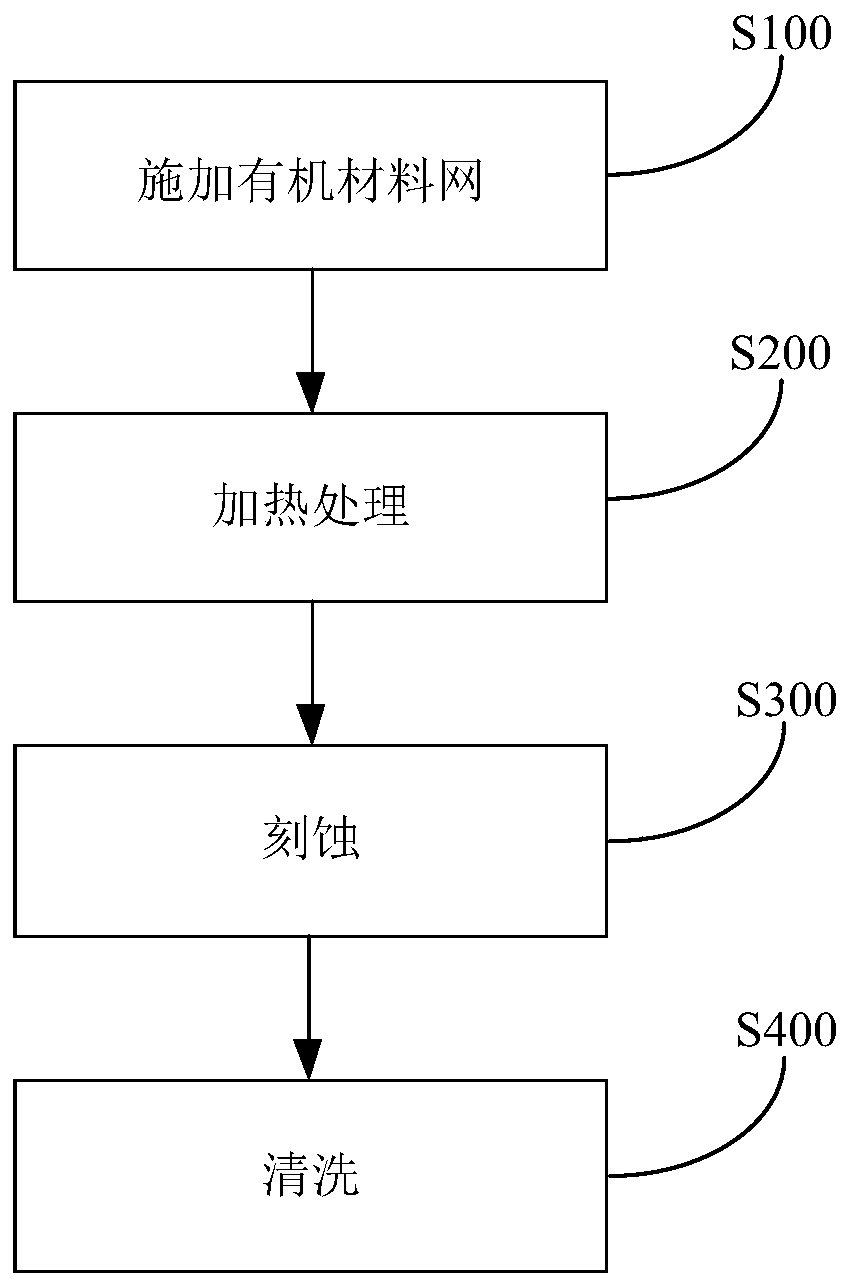

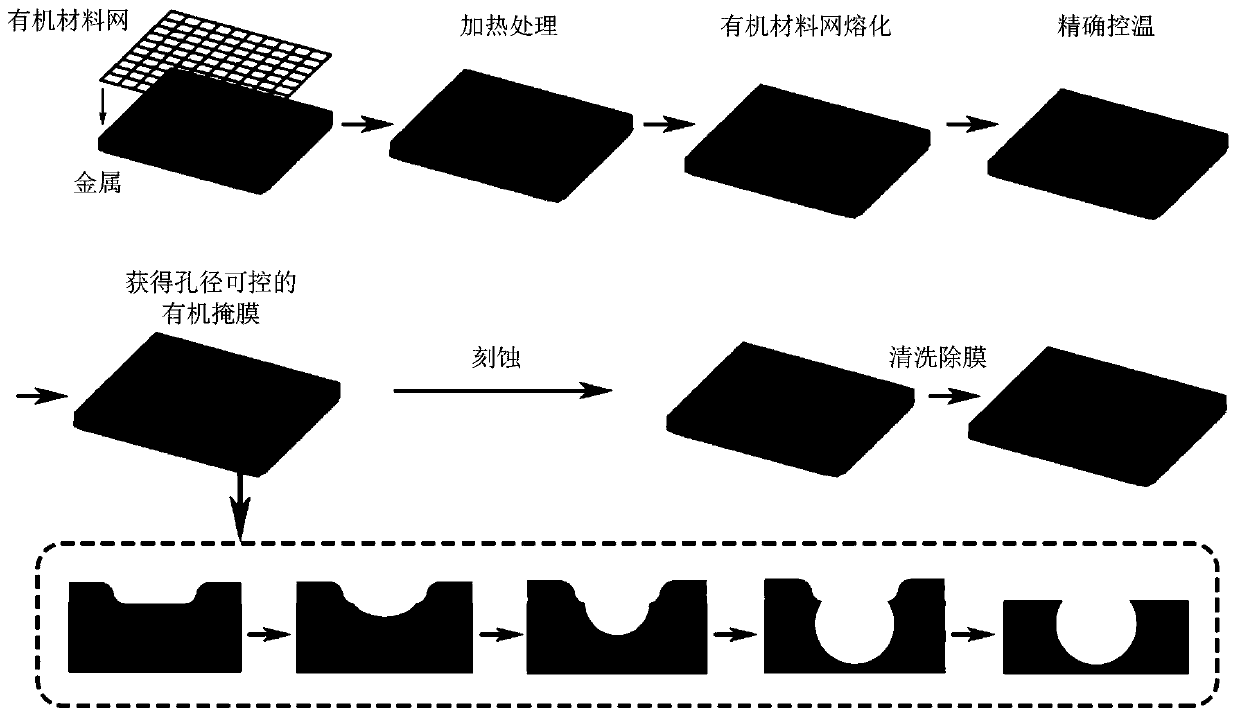

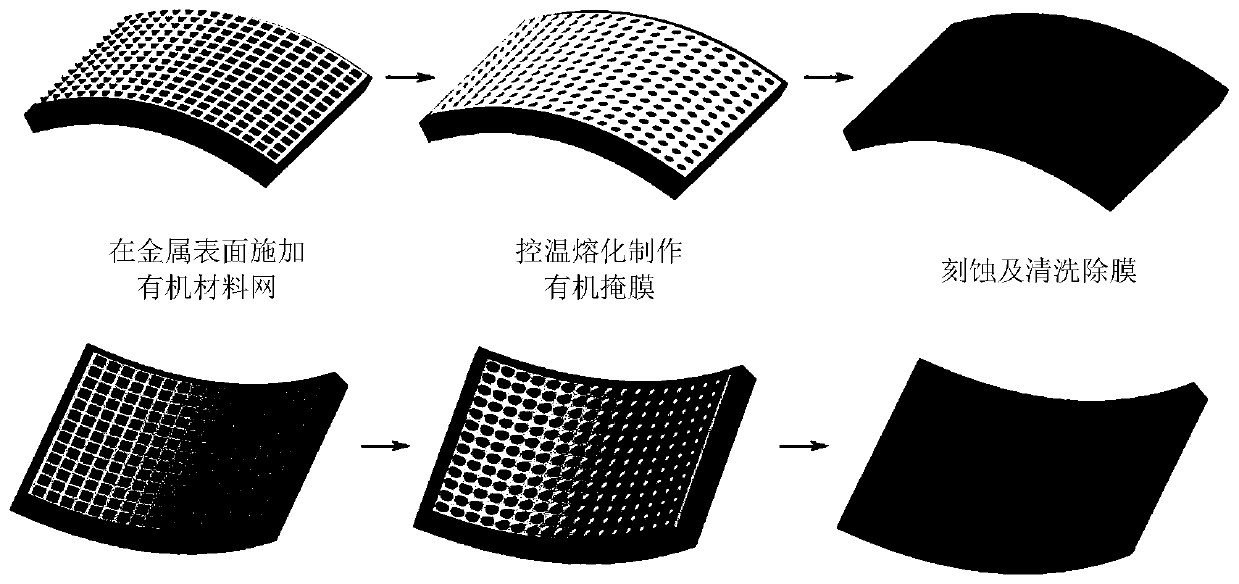

[0059] refer to figure 2 , according to the following steps to prepare a large-area micro-pit structure with superhydrophobic properties on a copper plane:

[0060] (1) Cover the metal surface with an organic material net (60 mesh, formed of nylon material), and apply tensile stress and compressive stress to the organic material net to make the organic material net closely adhere to the metal surface;

[0061] (2) heat-treating the sample obtained in step (1) to obtain an organic mask. The specific conditions of the heat treatment include: the temperature is 236.5°C, and the temperature is kept constant for 10 to 12 minutes; during the heating process, when the temperature rises above 225°C, the heating rate is adjusted to 1°C / min; the surface morphology of the obtained organic mask is as follows: Figure 5 , and its average pore diameter is about 213.8 μm;

[0062] (3) Electrochemical etching is carried out on the metal surface not covered by the organic mask, so as to obt...

Embodiment 2

[0065] refer to figure 2 , according to the following steps to prepare a large-area micro-pit structure with superhydrophobic properties on a copper plane:

[0066] (1) Cover the metal surface with an organic material net (60 mesh, formed of nylon material), and apply tensile stress and compressive stress to the organic material net to make the organic material net closely adhere to the metal surface;

[0067] (2) heat-treating the sample obtained in step (1) to obtain an organic mask. The specific conditions of the heat treatment include: the temperature is 236.5°C, and the temperature is kept constant for 10 to 12 minutes; during the heating process, when the temperature rises above 225°C, the heating rate is adjusted to 1°C / min; the surface morphology of the obtained organic mask is as follows: Figure 6 , with an average pore diameter of about 215.4 μm;

[0068] (3) Electrochemical etching is carried out on the metal surface not covered by the organic mask, so as to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com